Revolutionizing construction sites with hydraulic systems for construction machinery

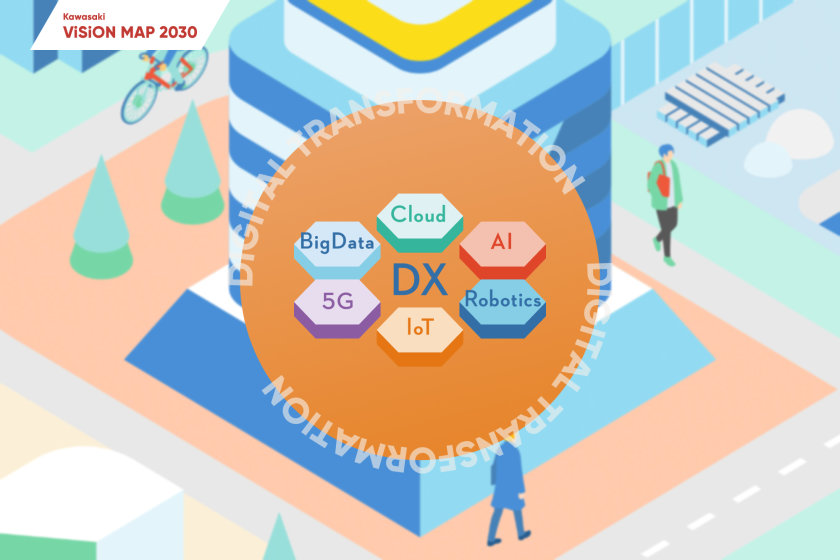

Hydraulic systems play an essential part in automating heavy equipment such as excavators, which aid civil engineering and construction. Solutions to labor shortage, increase in work accuracy, and improvements in safety can be achieved by reproducing the skills of experts and making operation easier. Here is the voice of an employee who engages in their development while feeling passion for what their monozukuri can offer to society. (This article is a part of Kawasaki ViSiON MAP 2030, which imagines the future of the Kawasaki Group.)

Precision Machinery & Robot Company

In 2009, Iwabe joined the company formerly named Kawasaki Precision Machinery Ltd. He has loved automobiles since childhood and even participated in Formula Student competitions. He joined Kawasaki upon realizing that he was interested not in part of a unit, but the machinery as a whole. He is currently involved in developing the hydraulic device control system for construction machinery.

Making heavy equipment easy-to-use to automate construction

My current goal is to improve the usability of hydraulic components mounted on construction machinery at construction and other worksites. What is most important is to achieve the automation and autonomy of heavy equipment. For example, in factories, many operations are automated and perform autonomously. Objects are transferred as programmed and robots take care of production and quality control, which helps resolve labor shortages, raise operational precision, and enhance safety. Construction sites face similar issues, and there is increasing research into the automation and autonomy of heavy equipment. If this goal is realized, experienced workers can transfer their expertise to machines and entrust on-site tasks to the equipment, concentrate on more difficult tasks, and work safely in remote spaces. As a hydraulic equipment manufacturer, Kawasaki intends to remove the complex motions typical of hydraulic devices that affect construction machinery so that the equipment can be made easier to handle.

Transferring the knowledge of skilled workers to machinery

To facilitate the use of hydraulic equipment, I am involved in developing control systems for excavators at construction sites. Oil pressure is used to create both powerful and delicate movements. In addition to the pursuit of higher efficiency, the systems enable automatic, autonomous operation. Existing hydraulic machines depend on human control, including visual checks and lever operation, and some tasks can only be carried out by experienced workers. I am working to reproduce the expert worker's intuitive operate correction on machines and enable anyone to perform precise work rapidly with the aid of electronic control. You may even see excavators operate autonomously at worksites by 2030.

Creating answers for the future through monozukuri (the creation of things)

My passion for monozukuri has not changed since I was a student. When I am able to make machinery move in the way I imagined after trial and error, I feel as if was able to emotionally connect with it. I hope that my work contributes to as many people as possible, which in turn benefits society. Improvements in hydraulic systems support the development of heavy equipment and innovate the field of construction. Beyond their current use, I anticipate that machines can take the place of humans in dangerous areas such as disaster sites. Hydraulic systems can also be used for heavy equipment in diverse areas. I hope that our endeavors to solve present issues will provide answers to the many problems present throughout society.

The information contained in the article is current as of December 2022.

"Kawasaki ViSiON MAP 2030" presents the future we want to realize by the year 2030, presented through the voices of Kawasaki staff working towards our vision. We hope you join us to learn about their efforts in social change, and to imagine the future we can achieve together.

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment