Kawasaki’s MINATOMAÉ system enables a suburban sea culture that delivers farm-fresh fish to city dwellers

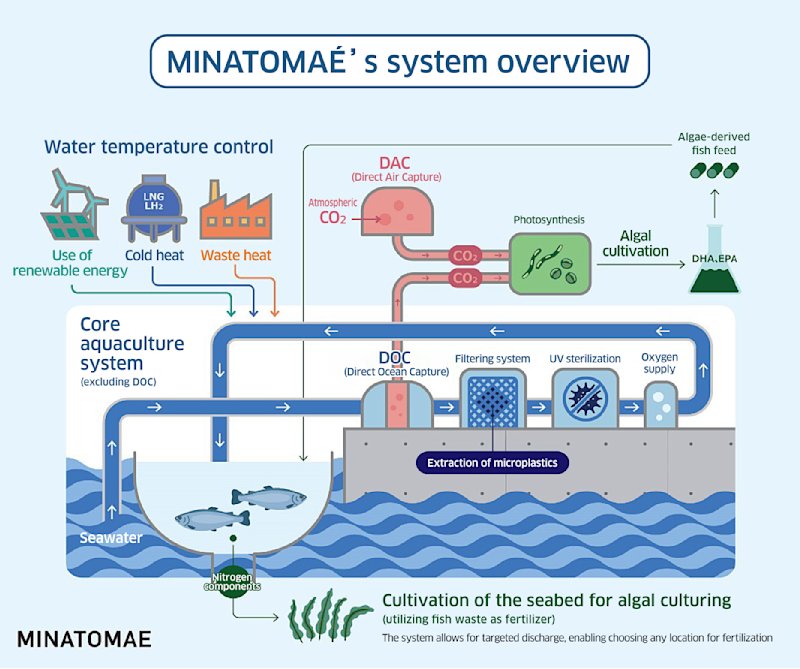

The global population is continuing to grow and is likely to reach 10 billion people in the near future, posing an enormous challenge to the world’s food security. To help solve this issue, Kawasaki is promoting sophistication of aquaculture systems by capitalizing on its expertise built up while developing a diverse spectrum of products over the years, thus contributing to sustainable development of the fisheries industry.

Advancing effective and reliable seafood supply systems

In the context of food security, securing protein resources by promoting aquaculture development is an overriding theme. Kawasaki took an innovative approach to addressing this theme and has developed the MINATOMAÉ system, which is seeing good prospects for commercialization.

MINATOMAÉ* system features technologies that enable fish farming at locations near ports in suburban areas. In order to establish these technologies, Kawasaki launched a demonstration experiment in January 2025, receiving assistance from Maruha Nichiro Corporation, a leading fisheries company. In the experiment, test farming was conducted to grow 900 trout salmon in the sea near the site of Kawasaki’s Kobe Works. Salmon is globally popular for its use in sushi. Particularly in Norway, it is one of its most important export items, with the government actively promoting large-scale fish farming of this species.

*"MINATOMAÉ” is a coined term derived from the Japanese words 'minato' (port) and 'mae' (in front), signifying the concept of conducting aquaculture in close proximity to the port.

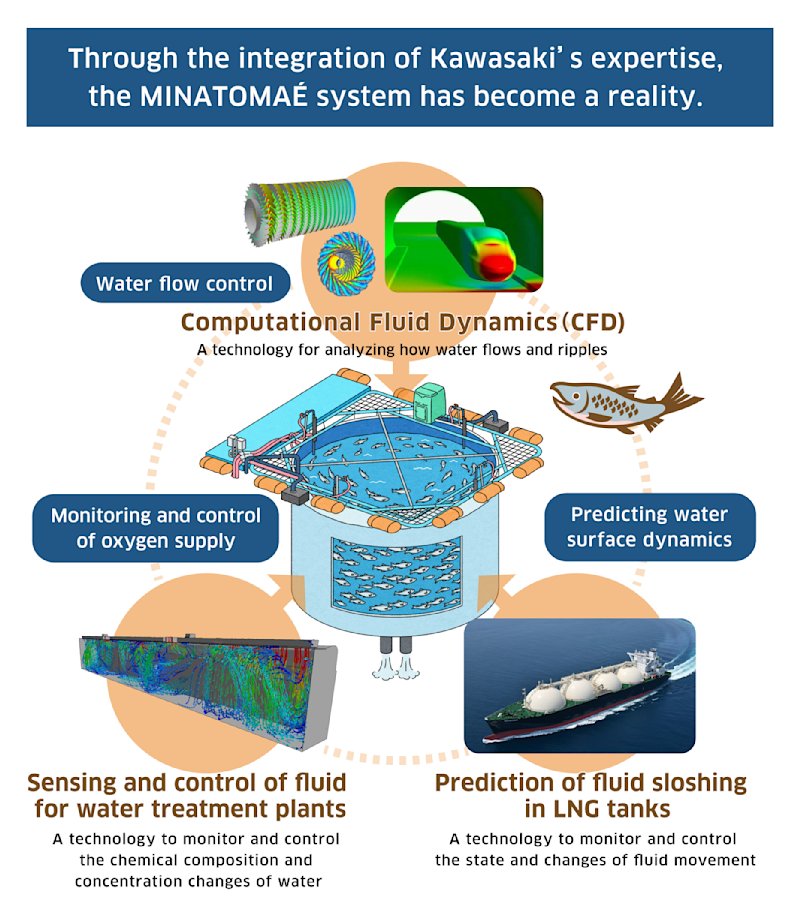

Why is Kawasaki, a company known for its expertise in heavy industrial manufacturing, promoting an aquaculture project? The answer is explained by the good applicability of technologies developed by the heavy industry to creating aquaculture systems. The MINATOMAÉ system specifically was developed by bringing together various technologies related principally to: 1. computational fluid dynamics (CFD) analysis and simulation (used for gas turbines and railroad vehicles); 2. dissolved oxygen level measurement and analysis (for water treatment plants); 3. purification (for water treatment plants); and 4. fluid sloshing control (LNG tanks).

Atsushi Sano, manager of the MINATOMAÉ project and Food Security Solution Project Manager at the Corporate Technology Division, described the reason for the company deciding to undertake the project as follows: “Fish farmers are experts in growing fish in sea culture, but they have little expertise in creating an optimal sea culture environment. Looking at this situation, we thought we could create a comfortable fish farming environment by combining an array of sophisticated technologies that we built while working on many plant engineering projects.” In this innovative system, as just described, various technologies have been utilized to build a new form of infrastructure to support food supply channels.

Creating a farming environment with less stress on fish

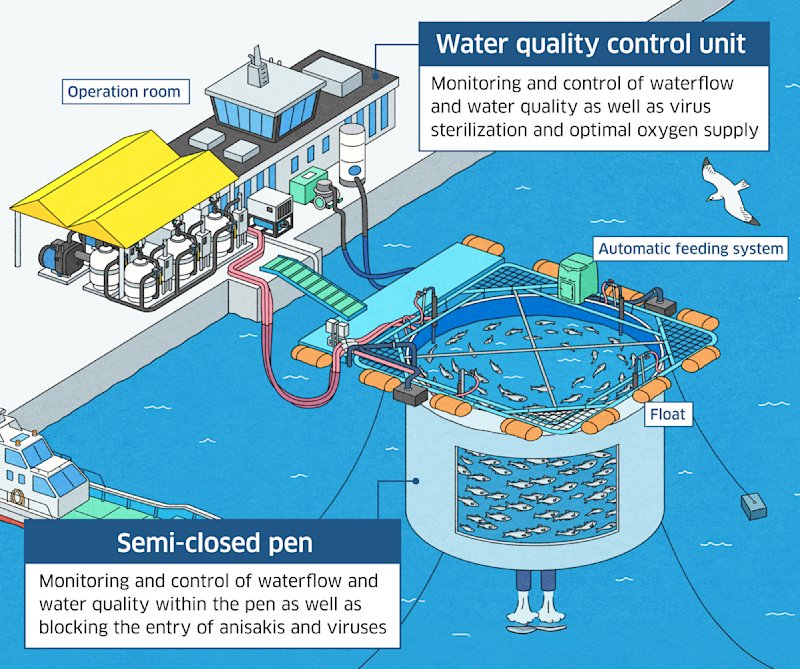

MINATOMAÉ adopts a closed pen with an inflatable pool-like structure. In this base framework, a range of functions, such as seawater pumping and filtering and UV sterilization, are installed in order to reduce stress imposed on fish in this environment.

Achieving Japan’s highest-ever fish farming density at 6%

The MINATOMAÉ project started demonstration experiments from 2022 by conducting four aquaculture tests while receiving support from Maruha Nichiro and using the company’s aquaculture site. This was followed by a fifth test in the period between mid-January to late-April 2025 in the sea near the site of Kawasaki’s Kobe Works, in which trout salmon were cultured with a farming density of 60 kg (of fish)/ton (total fish weight of 1.7 t per 30 t of seawater), the highest level in Japan for this target species. The fish, which grew to weigh 2 kg each on average, were harvested for shipping. The farmed fish grew generally at the expected rate, although some grew faster, even exceeding 3 kg, when harvested, indicating good results. It should be particularly noted that this successful demonstration confirmed the system’s capability with regard to large production capacity from high-density farming, and this has significant implications for the possibility of operating aquaculture sites utilizing the sea near ports and coasts, seeking to reduce transportation costs and energy usage while ensuring stable supply.

Scaling-up facilities toward full-fledged commercialization around 2027

Following the trout salmon culture test farming conducted near the Kobe Works’ site, a test culture of yellowtail was carried out. At present, the MINATOMAÉ project is preparing to perform verification for scaling-up the pen facilities with an eye toward starting full-fledged commercialization by fiscal 2027. Having established its strong capacity to more than fully satisfy the two key requirements for good quality cultured fish, namely good physical growth and fish odor control, the project is aiming to achieve 10 billion yen in sales by around 2040.

Corporate Technology Division

Kawasaki Heavy Industries, Ltd.

MINATOMAÉ brings technological innovation to aquaculture operations

The very beginning of the whole plan was when I attended an international conference on oceanography, where I happened to be present at a session on offshore aquaculture. This inspired my interest in the possibility of applying Kawasaki’s technologies to develop a project in this field, and I took initial steps to submit a related proposal to the company. I was very happy that the proposal was approved, and the project was able to receive support from Maruha Nichiro and successfully conduct test farming near Kobe Works. The global population is continuing to grow and will likely reach 10 billion people in the near future, giving rise to concerns over a possible protein crisis and a threat to food security, while aquaculture operations are suffering from severe damage due to red tides and increasing seawater temperature. By improving the availability of quality controlled, locally sourced seafood even in urban areas, the MINATOMAÉ system is capable of offering a solution to these issues, which has significant social implications. I’m looking forward to seeing many people commonly enjoy fresh fish from farms enabled by Kawasaki’s technologies.

Environmental System Research Department

Technical Institute,

Food Security Solution Project,

Corporate Technology Division

Kawasaki Heavy Industries, Ltd.

We can create a uniform aquaculture environment regardless of species

As an engineer specializing in the chemistry field, I have been engaged mainly in the development of sewage treatment plants. I am proud to be part of the MINATOMAÉ project, the purpose of which is to develop a new aquaculture plant system by mobilizing Kawasaki’s plant engineering capabilities, with the aim of enabling the creation of an optimal fish farming environment in urban areas close to consumption centers regardless of species. I like to see fish growing in the facility environment created from our development capabilities.