What is Carbon Neutrality for Japan? Efforts for Decarbonization Boost Growth.

Following the 2050 Carbon Neutrality Declaration of the government of Japan, many companies have now accelerated their activities for decarbonization. The Kawasaki Heavy Industries Group has been expanding business in mobility, energy, the environment, and industrial equipment for more than 120 years since its foundation. This article shows Kawasaki’s motivation and advanced activities to serve in the realization of a decarbonized society by integrating its technologies and knowledge.

Not to Eliminate CO2 to Zero. But a Balance between Carbon Emissions and Absorption for Carbon Neutrality.

In October 2020, Prime Minister Suga Yoshihide declared that Japan intends to reduce greenhouse gas emissions to net zero and make Japan a carbon-neutral, decarbonized society by 2050. Suga also announced Japan’s new target of a 46% cut in CO2 emissions by fiscal year 2030 compared to 2013. Accompanied by this high goal, the Green Growth Strategy by Achieving Carbon Neutrality in 2050 was formulated to encourage dynamic innovation from private companies and assist them in accepting the challenges of a new era. This has gradually caused new business development and a change of course for controlling greenhouse gases in the private sector.

What exactly does carbon neutrality mean? Carbon is a component of CO2, and neutrality means not taking sides. However, note that Suga mentioned “greenhouse gases.” The carbon neutrality that the Japanese government targets not only relates to CO2 but also the greenhouse gases that include methane, N2O (nitrous oxide), and fluorinated gases. In addition, pay attention to the statement, “to reduce emissions to net zero.” “Net zero” means that emissions of greenhouse gases balanced by absorption and removal are to be zero. In other words, the amount that has to be absorbed or removed to achieve net zero, since it is technically difficult to completely suppress greenhouse gas emissions. This is the carbon neutrality promoted by the Japanese government.

CO2 originally exists in the air, on the earth's surface, underground, and in water. While carbon is discharged in the form of CO2 into the air from the respiration of organisms and the burning and decay of organic matter, plants take in CO2 during photosynthesis, and the oceans absorbs CO2 from contact with the air. Carbon is circulating, and the quantity in each state is stable. There are the fossil fuels of oil, coal, and natural gas underground. Since human beings mine and use them for energy, discharging carbon into the atmosphere, the carbon level in the air rises and causes global warming.

Tatsuya Watanabe, president of Energy Solution & Marine Engineering Company, says, “What we aim at is not carbon zero but carbon neutrality. A certain amount of CO2 is necessary for living things. It is important to modify our actions to limit excessive emissions or, speaking of extremes, to recycle the carbon. Though hydrogen energy attracts attentions now, the production process emits CO2. The crucial point is to use hydrogen in a CO2 neutral condition.” The annual CO2 emissions in Japan are equal to 1,213 million tons (in fiscal 2019, according to the National Institute for Environmental Studies). How can we decrease this huge volume of CO2 emission? A lot of issues remain to be solved.*1

*1 See the Agency for Natural Resources and Energy of the Ministry of Economy, Trade and Industry (METI), “What is ‘Carbon Neutrality’ all about? (Part 1) - Who will realize it, and when?”

Carbon Neutrality Forwarded by Kawasaki. Actions to Become CO2 Free in Business Processes

The Kawasaki Heavy Industries Group operates in diverse fields that include rail cars, aircrafts, energy- and environment-related products, industrial equipment, and motorcycles. Its environmental management activities began with the formulation of the first Environmental Management Activities Plan in 1994, followed by the Environmental Charter in 1999, which defines the basic philosophy and code of conduct guidelines, and the Environmental Report, which was the first in the heavy manufacturing industry.

Subsequently, in the context of the increasing requirements for global warming worldwide, including the Paris Agreement that was effectuated to mitigate climate change, and the Sustainable Development Goals (SDGs) adopted by the United Nations, Kawasaki Global Environmental Vision 2050 was prepared to set higher objectives. The Company specifies key strategies to realize CO2 Free (low-carbon society), Waste Free (recycling-oriented society), and Harm Free (society coexisting with nature), and advances further environmental management to achieve the Group Mission of “Kawasaki, working as one for the good of the planet.”

The 10th Environmental Management Activities Plan (fiscal years 2019 to 2021) particularly promotes activities that emphasize the realization of CO2 Free by working to significantly cut CO2 emissions through further reductions in CO2 emissions from business processes and the expanded provision of low-CO2 products.*2

Since purchased electricity accounts for a large portion of energy consumption by Kawasaki, proactive use of onsite power generation facilities, the use of renewable energy from solar power generation facilities, and energy-saving activities are principally promoted.

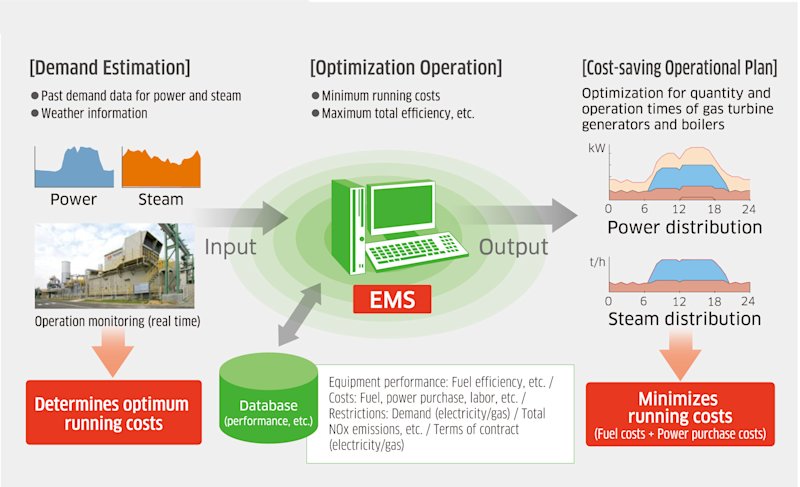

Yoshihito Ando, Senior Manager of the Environment and Energy Management Department, says, “Presently, onsite power generation facilities are in operation at the Akashi Works, Kobe Works, and Gifu Works. At the Akashi Works, the Factory Energy Management System (FEMS), which was developed in-house, has been introduced. The actual use of power is recorded and analyzed in the system for efficient use of electricity throughout the year.”

The Energy Management System (EMS) is a complex energy facility that consists of gas turbines, gas engines, boilers, and different types of equipment to optimize the output distribution and operation pattern for each piece of energy equipment, which minimizes running costs. The system of the same type for factories is called FEMS.

Moreover, solar power generation facilities have been installed at the Seishin Works of Kawasaki as a Power Purchase Agreement (PPA) model. PPA is a contract for the direct sales of electricity between electricity retailers and users. In Japan, the term “PPA model” often refers to a business model for the free installation of solar power equipment. The owner of a photovoltaic system installs it on the roof of a business operator without charging for the costs, and the operator purchases the generated electricity.

Ando talks about the effect, “Presently, 3% of the electricity used at the Seishin Works is covered by photovoltaic power generation. Though it is still a small amount in consideration of the total energy consumed at the plant, the point is the power is generated with completely zero CO2 emissions. The model is highly advantageous in terms of the costs because of the low initial investment and reduced electricity bills, and other works are examining the implementation of the model.”

In addition, the internally developed energy visualization system (K-SMILE) was introduced to major works to promote energy savings. Ando explicates, “Our Company is an early player in energy-saving activities. Implementation of K-SMILE allows us to comprehend the actual status and find waste and uneven use of facility operations. It is also possible to detect signs of future system failure.”

From now on, the configuration of energy suppliers will be optimized with guaranteed safety based on S+3E (Safety, Energy security, Economic efficiency, and Environment).

Kawasaki switched the electricity used at the Kobe head office to CO2 free in July 2021. The power is supplied by Kawasaki Green Energy, Ltd., a Group company of Kawasaki, to Kobe Crystal Tower, which houses the Kobe head office. Essentially, the power becomes 100% renewable energy-derived and compliant with the RE100*3 criteria, achieving net zero carbon emissions from power use at Kobe Crystal Tower and an estimated 2,000-ton reduction in CO2 per year.

In addition, energy optimization across multiple plants using the Multisite Energy Management System (MEMS) is encouraged instead of studying it per plant as in the previous era. Furthermore, the establishment of the internal carbon pricing (ICP) system, where the CO2 emissions reduced by introducing energy-saving equipment is evaluated by determining the price, is also considered. This helps overcome the tendency for investment in the equipment directly linked to production to be prioritized over energy-saving items.

Ando describes the desire for environmental conservation activities, “The American Indian proverb says, ‘We do not inherit the Earth from our ancestors; we borrow it from our children.’ We enthusiastically work to protect the environment for the future children as if we were members of the Earth Defense Force.”

*2 See the press release of Kawasaki Heavy Industries, “Kawasaki Establishes Global Environmental Vision 2050 - Pursuing Three ‘Frees’: CO2 Free, Waste Free, and Harm Free” on August 9, 2017.

*3 Stands for Renewable Energy 100%. It is a global corporate initiative with the goal of sourcing electricity used for business activities entirely from renewable energy sources.

Reducing CO2 Emissions via Product-Based Contributions. In-house Ranking of Products Satisfying Internal Standards.

Kawasaki seeks to realize a low-carbon society by providing products that generate low CO2 emissions during use. Ando says, “Our products emit more than 100 times greater quantities of CO2 during operation than our business activities. It is also a weighty responsibility to release low-emission products into the world.”

There is a program to boost the environmental performance of products and accelerate the reduction in the environmental impact caused by associated manufacturing processes. The products selected for this program must meet self-established criteria and are categorized as either Kawasaki Green Products or Kawasaki Super Green Products. The products are then labeled as compliant with ISO 14021, and the list is made public. In addition, the Company recognizes products for the Kawasaki Environmental Award from among all registered products of the Kawasaki Super Green Products that have received external evaluations related to the environment and contributed significantly to business management during the target period. In 2020, the M5A-01D Gas Turbine won the award for achievement of world’s best power generation efficiency and environmental performance in the 5 MW class.

The rules for calculating CO2 emission reductions through product-based contributions have been specified, and the calculations based on these rules showed that CO2 emissions reduction through products sold by Kawasaki in fiscal year 2019 was about 23.14 million tons.

Kawasaki Green Products - a part of registered products in 2020

Advanced Technologies of the Front Runner in the Arena of Utilization of the Ultimate Energy, Hydrogen

Now, hydrogen attracts great attention as energy to realize a decarbonized society. Kawasaki, a leader in the hydrogen energy industry, promotes technological innovations.

Watanabe says, “Many conventional primary energy sources, such as oil, coal, solar, and wind, cannot be stored after conversion into secondary energy. For hydrogen, surplus power is used in the electrolysis of water into hydrogen, and this power-to-gas process enables storage and travel in terms of space and time. In addition, hydrogen gas as an energy source becomes water after use while oil and coal will generate CO2 and other gases after burning and are no longer convertible. Hydrogen is the ultimate energy in that it is recyclable by transforming into water.”

Kawasaki develops hydrogen energy technologies in the processes of production, transportation, storage, and utilization. Kawasaki initiated the world’s first demonstration tests to produce hydrogen from brown coal from Australia and transport it to Japan via liquefied hydrogen carrier; supplied both heat and power to urban areas using a gas turbine fueled by 100% hydrogen; started combustion testing of gas turbines compatible with 100% hydrogen; promoted research and development of combustors for hydrogen-fueled aircraft; and developed other progressive activities to lead the world.

In May 2021, a carrier capable of transporting liquefied petroleum gas (LPG) and ammonia was constructed. The demand for ammonia is expected to grow in the energy sector because it does not emit CO2 during combustion.

Watanabe comments, “Energy carriers for efficient storage and transportation of hydrogen include liquefied hydrogen, ammonia, and organic hydrides. I think these three will be used in a different manner in the future. Ammonia is used in agriculture as fertilizer, as well as in other industries, and transportation techniques are already established. It is possible that the technology to use this substance as a hydrogen energy carrier will rapidly develop from now.”

Watanabe also mentions the future style of manufacturing, “I believe the foundation of manufacturing will never change, no matter how fast information technology develops. For example, when you want to keep liquefied hydrogen at -253°C in a carrier or a tank with a large capacity, the technology is always important. What could be improved with the use of information is the efficiency of production and the speed of delivery to the customer. We continue to inherit the secret of manufacturing that can be realized only by Kawasaki while, for other aspects, it is necessary to cooperate and build alliances with other companies. The attempts to make everything by ourselves will lead to the loss of international competitiveness and domestic market share, resulting in another case of the Galapagos syndrome. Strategies from a global viewpoint become more and more important.”

Activities for CO2 Separation, Capture, Effective Use and Storage. Remarkable Energy Reduction by Means of Solid Sorbents

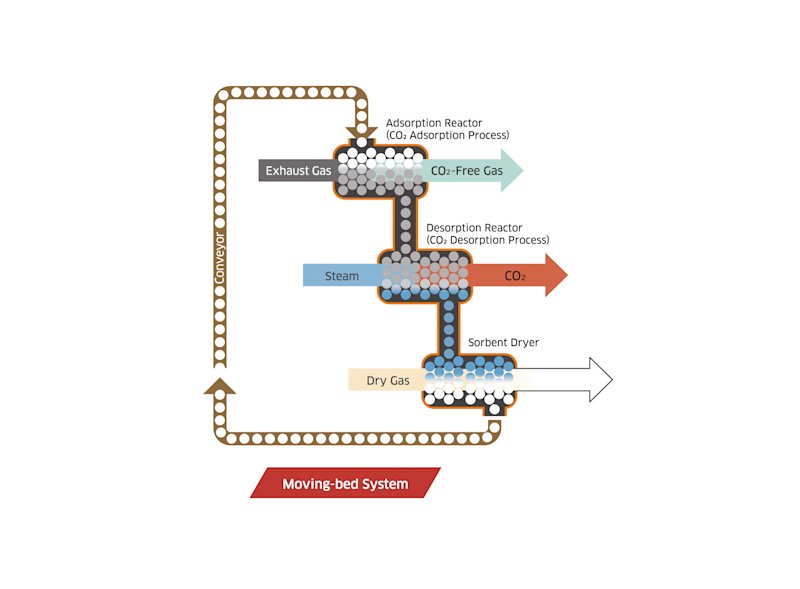

With regard to the CO2 generated by plants, the establishment of the Carbon dioxide Capture, Use, and Storage (CCUS) system is also necessary now. Kawasaki is involved in the research and development of a CO2 separation and capture system. The Kawasaki CO2 Capture (KCC) moving-bed system with the use of solid sorbents was developed and modified to improve the separation and capture performance of CO2. This was carried out together with the Research Institute of Innovative Technology for the Earth (RITE) as a project commissioned by the METI in fiscal year 2015 titled Research of Carbon Dioxide Recovery Technology for Commercialization, which has been administered by NEDO since fiscal year 2018.

The system verified at the Akashi Works was extended, and pilot-scale testing facilities were constructed with the aid of the Kansai Electric Power Company (KEPCO) at its Maizuru power station. The experiments to separate and capture CO2 in the combustion emissions generated from the coal-fired power plant will start in fiscal year 2022.

Hiroyuki Kashihara, manager of the Thermal System Research Department, Technical Institute, Corporate Technology Division, explains, “CO2 separation and capture technology has been common in chemical plants for a long time. What we are developing is a system to achieve energy savings at low cost. Though amine solutions have been used conventionally, CO2 desorption requires sufficient energy to heat to 120ºC to 130°C, which is higher than the boiling point of water. Since solid solvents do not contain water, 60°C is enough, and the low-temperature thermal energy that has been discarded can be used. This solid sorbent system is expected to achieve energy reduction by more than 40% compared to traditional methods.“

Technical development and other activities to realize carbon neutrality and a decarbonized society are being accelerated. The actions for global warming were considered restrictions on economic growth in the previous era, which has ended, and we are gradually coming to understand the restrictions as opportunities for companies to develop from a long-term perspective.

Kawasaki reduces CO2 emissions through business processes and during the use of its products, and develops the technology to separate and capture CO2 as well. Thus, aiming at realization of decarbonized society, the Company solves environmental issues, contributes to economic revitalization, and pioneers a sound future.

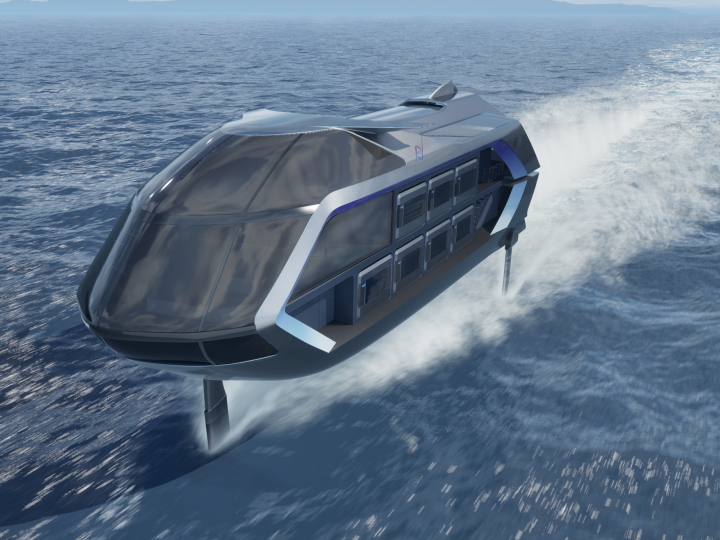

Energy Solution & Marine Company

Kawasaki Heavy Industries, Ltd.

Environment & Energy Control Department

General Administration Division

Kawasaki Heavy Industries, Ltd.

Thermal System Research Department

Technical Institute

Corporate Technology Division

Kawasaki Heavy Industries, Ltd.