Crushing Technology that Revitalizes the Earth

Crushing and pulverizing technologies that are used in many industries are now being applied to the utilization of plant biomass. These technologies are behind the activation of microbes that are reviving the power of the good earth.

Compost that Revitalizes Soil and Supports Organic Farming

The Notsu District of Usuki City in Oita Prefecture is known as “a village of Kicchom Minwa (folktales about a witty man named Kicchom) and Kakure Kirishitan (underground Christians).” Here, Hiromi Fujishima, whom we interviewed in mid-June, owns a farm where we observed many cabbage butterflies hovering around his early summer vegetables.

“Because we don’t use agrochemicals, they flock to the crops. In organic farming, insects are part of the cultivation cycle, but we limit crop damage by using agricultural nets and other means of control that do not require agrochemicals. It’s labor-intensive work, but the resulting crops are tasty and full of nature’s blessings,” comments Fujishima.

His organic farming is supported by a matured compost called Usuki Yume Taihi (“Usuki Dream Compost”), produced by the Usuki Soil Manufacturing Center which is run by the Usuki City Ecological Agriculture and Forestry Promotion Public Corporation. He annually uses about two tons of this compost per 1,000 m2 for his 7,500 m2 farm.

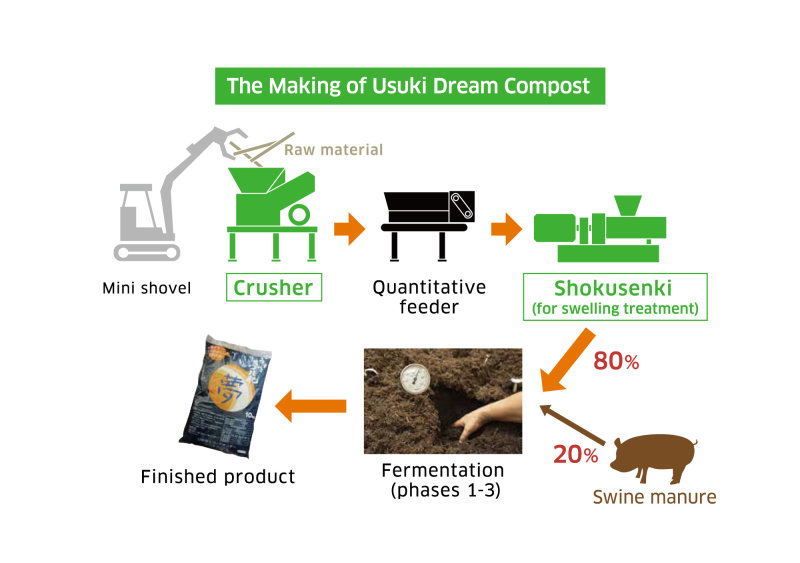

Most compost is made of livestock manure, but 80% of the Dream Compost derives from pruned trees and other plant biomass. In the compost-making process, the plants’ main element, carbon, is turned into humus via microbial decomposition, greatly enhancing the soil’s ability to nourish crops. This process restores the soil to its natural, original state, or what Usuki farmers call “real soil.”

The texture of the soil mixed with this compost is free-flowing, without the stickiness typical of soil amended with compost made from livestock manure. “You can tell that the compost’s aggregate structure is changing the property of the soil. In this soil, vegetables grow stress-free,” Fujishima says laughingly.

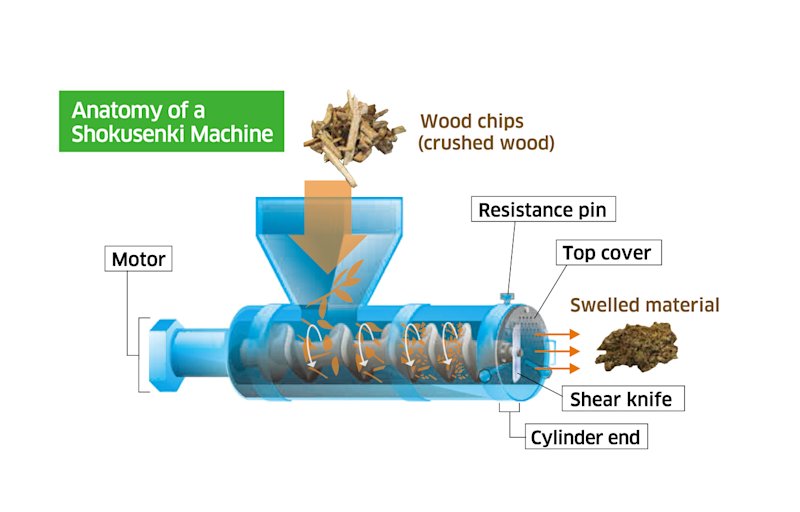

The manufacturer of the crushing/swelling system used for producing this compost is EARTHTECHNICA, a member of the Kawasaki Group. For the swelling treatment, the company offers a proprietary machine, the "Shokusenki," which is capable of applying pressure, mixing, crushing, heating, and expressing the moisture contained in plant biomass. In the final stage, this machine releases the pressure and fluffs up the material so that it will be an optimal environment for microorganisms.

Although plant biomass has long been recognized as a nature-friendly, useful resource, many unresolved challenges in treatment methods remained. By using its proprietary swelling treatment technology to resolve them, EARTHTECHNICA became a game changer, turning plant biomass into a multi-purpose resource. At the same time, crushing technology, originally developed for crushing and pulverizing rocks, is now being used by many sectors as people- and eco-friendly applied technology.

What It Took to Make Hommamon (“Real”) Products

As to why Usuki City is committed to producing compost, even to the point of establishing a dedicated facility – Usuki Soil Manufacturing Center – Yasuhiro Nakao, assistant manager of the Ecological Agriculture and Forestry Promotion Public Corporation, explains that it was because they realized that supporting the production of good soil was a prerequisite to promoting organic farming.

Asked why Usuki City decided to launch organic farming initiatives in the first place, he said that the city had two reasons. One was to source healthy vegetables for school lunches. The other was to provide the local community with vegetables full of flavor and “vitality,” and free of agrochemicals.

Shinsuke Hirose, Deputy Director of the Organic Farming Promotion Office of the Agriculture and Forestry Promotion Section of Usuki City, comments, “We have been working for more than 10 years to produce organically-grown hommamon farm products in order to revitalize farming in the city.” Currently, about 60 households are practicing organic farming to produce hommamon products. Participating farmers use the Dream Compost and the city conducts annual analyses of their soil. Once certified, producers are allowed to put on their farm products stickers with the character “HO” (for HOmmamon) in white on a gold background as proof that they have met the city’s criteria.

Hirose explains that sweet potato is among the highest value-added products, in regard to which the growers were able to launch a brand they call Kanta-kun (“Mr. Sweet”). Another star product is bell pepper, with some farmers shipping an amount worth 30 million yen (USD 285,000) annually.

Every year, Usuki City accepts four to five people who wish to begin farming for the first time. Two types of trainees are solicited for this program: Chiiki Okoshi Kyoryoku-tai (city revitalization team members) who undertake a three-year course to become independent professional farmers and Agri Kigyo Gakko Kenshusei (agricultural startup trainees) who take a one-year bell pepper cultivation course to become professional growers. The number of trainees is unusually high compared to other cities with similar programs, proving that the trainees’ vision of farming and the city’s organic farming strategy “resonate” beautifully.

While the city offers the Dream Compost at 5,000 yen (USD 46.00) per ton, it purchases a ton of raw material (pruned tree branches) at only 300 yen (USD 2.80) per ton. During our interview, a local welfare organization brought in a truckload of pruned tree branches. They said that selling the raw material has been helping fund their activities. The city’s organic farming efforts are therefore creating an eco-system through which various entities are connected.

The Method of Crushing and Cutting Determines the Quality of Soil Made

It takes six months for the Dream Compost to be ready for distribution, as the raw material needs to undergo crushing, swelling, and three-phase fermentation processes. Annually, Usuki Soil Manufacturing Center manufactures 1,600 tons of the compost. In more detail, the compost-making has four stages: 1) Crushing, 2) Air Separation, 3) Quantitative Feeding into the Shokusenki, and 4) Swelling. EARTHTECHNICA’s system is used for the entire cycle.

Pruned tree branches delivered to the Center by forestry associations and other groups are fed into a crusher with rotating double-sided blades to become 5-cm-long wood chips.

Koki Takeo of the Center comments, “The raw material – pruned tree branches – comes with different vegetative properties unique to that locale. We’ve spent about a year testing, trying to figure out an optimal method of crushing for each location, as the composition of the raw material varies from place to place. Some biomass has a high percentage of bamboo; others may contain a large amount of trees with soft fibers.”

After crushing, wood chips go through the air separator where foreign objects such as stones and materials with a heavy specific gravity are removed. The chips are then transported to a quantitative feeder before entering the Shokusenki, which determines the quality of the compost. The model used at the Center is the SM30-110 – a motorized, 0.5-m-wide, 4-m-long, cylindrical apparatus which processes 2 tons of raw material per hour.

Inside the cylinder, a large feeding screw is rotating to crush the wood chips, applying high pressure as the chips move from the entry point to the discharge point. Because of the pressure, heat is generated and the moisture in the wood chips evaporates as steam.

Then, the compressed wood chips enter the cylinder end – the highlight of the process in the Shokusenki. The 50-cm-long section has three 15-cm-long resistance pins, which are 5 cm in diameter and are attached to three different points around the circumference, and which further compress and break raw materials into fibers. The chips are then sheared into even smaller fragments by a shear knife rotating near the discharge point and ejected from the discharge holes.

To facilitate fermentation, the Center mixes livestock manure with the discharged material at a ratio of 2:8 before the mixture goes through a three-phase fermentation process. In the first month, the mixture is constantly agitated to promote fermentation. Then, after two more fermentation phases, it is ready for distribution. The entire process takes about six months.

From Technology that Fights Nature to Technology that Revitalizes It

Tokio Kayaba, Manager of the Sales Department at EARTHTECHNICA, who has been in charge of developing and marketing the Shokusenki, comments, “In the compact space of the cylinder end, all actions required for swelling the material take place successively and seamlessly. The quality of the resulting humus is determined by how well these activities go, especially the crushing of the resistance pins, the effectiveness of the shear knife, the way in which the release of pressure affects the swelling, and how the swelled product is broken down into fibers. We have a comprehensive knowledge of all these processes.”

The shear knife is an ultra-hard tool, thermally-sprayed with tungsten carbide. Along with the resistance pins, the performance of the shear knife significantly affects the Shokusenki's overall effectiveness, as the knife is used immediately before discharge.

A certified Compost Manufacturing Manager, Kayaba has long been on a mission to identify the relationship between composts and soil. The process of making plant-derived compost is, in effect, reproducing what a mountain does in creating a mass of leaves over a very long period of time by artificially creating an optimal environment for microbes - the main players in compost-making - to work.

EARTHTECHNICA has been expanding the application of crushing, pulverizing, sorting, and other fundamental technologies to many different fields - from things as large as rocks to ultra-fine products such as copy machine toner. Today, these technologies are indispensable for crushing and pulverizing plant-derived biomass, the material previously deemed difficult to recycle.

Kayaba adds, “A heavy-duty technology developed for crushing and pulverizing rocks and other hard materials - which could be described as “nature-fighting technology” - has been found to be useful for handling vegetation. This technology is now being used to make high-quality compost, creating people- and eco-friendly soil, and supporting organic farming. The real thrill of applying Shokusenki technology is knowing that it can bring about a new eco-cycle.”

Verifying the Usability of Bamboo Powder: Turning a Huge Challenge into an Asset

Because bamboo is one of the hardiest plant species that grows in the fields and mountains of Japan, its removal has been a challenge. In cooperation with Leave a Nest Co., Ltd., a science education company in possession of extensive knowledge in agriculture, EARTHTECHNICA launched a project in May 2019 to pulverize bamboo using Shokusenkis, and to verify its effects on soil and on crop growth/harvest. (The test site is located in Masuda City, Shimane Prefecture.)

It is expected that the test will reveal – physically, chemically, and biologically – the efficacy of powdered bamboo as a soil conditioner. If proven effective, the powder will facilitate the recycling of bamboo and significantly reduce the damage it causes.

Sales Department

EARTHTECHNICA CO., LTD.

Crushing/Pulverizing Serving as a Vital Technology for Environmental Conservation

EARTHTECHNICA develops, manufactures, and markets machines that crush or pulverize various materials. We have delivered our products to operators of mines and quarries where many crushers and pulverizers are used. In recent years, however, technologies for these machines have become recognized as valuable contributors to environmental conservation. For example, crushing/pulverizing scrapped cars, plastics, concrete, and other industrial waste has resulted in the reuse of resources. Currently, our environment-related business is focused on three sectors - scrap steel, plastic packaging, and industrial/construction waste - and it has become one of our pillar businesses.

Against such a backdrop, our company acquired the Shokusenki Machine business of Shinkozoki Corporation in 2017 to reinforce our eco business. Our Shokusenkis, which use swelling technology to convert pruned branches and other biomass into useful resources, have been delivered mainly to local governments in Japan.

We are exploring new applications for the Shokusenkis, and bamboo is now on the top of our list. Bamboo does not biodegrade easily, is hard to reuse, and its encroachment into woodlands near populated areas has been a problem. We are exploring the possibility of using our Shokusenki to turn bamboo into powder for use as a soil conditioner and livestock feed.

Some existing customers of our crushers are considering expanding into the farming sector. We would like to market our Shokusenki widely to these customers. Crushers and Shokusenkis have the potential of expanding our existing customers’ new businesses more than ever. We will continue to improve our products so that the biomass resources they produce will contribute to expanding our customers’ business horizons.

Representative of the Hommamon Agricultural Crops Promotion Network

Agriculture and Forestry Promotion Section

Usuki City

Usuki City Ecological Agriculture and

Forestry Promotion Public Corporation

Environmental Machinery Sales Section

Sales Department

EARTHTECHNICA CO., LTD.

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment