Unleashing clean hydrogen power

The past two years have seen skyrocketing interest in hydrogen fuel. According to the Hydrogen Council, more than 1040 large-scale hydrogen energy projects, equivalent to $320bn in direct investment through 2030, have been announced as of May 2023, an increase of 53 per cent since September 2022.

Driving these trends is the growing concern over climate change and mounting pressure to transition away from fossil fuels to renewable energy, which can be stored, transported and then later used in the form of hydrogen. Equally significant are heightened concerns about energy security. With LNG prices surging and geopolitical tensions unlikely to ease soon, governments are scrambling to diversify their energy sources. Hydrogen is a key candidate.

In March 2022, the EU raised targets for renewable hydrogen deployment in the bloc by 2030, from 5.6m metric tons to 10m metric tons of renewable hydrogen produced domestically and another 10m metric tons of imported clean hydrogen. Governments elsewhere have announced their support as well. For example, the US is allocating $9.5bn in funding to develop hydrogen hubs and scale up electrolyser technology, while Japan is investing ¥2tn ($13.5bn, 1 USD= 148 JPY) to support liquefied hydrogen value chains, among other technologies.

Despite such momentum, the actual deployment and use of hydrogen power is lagging. Two key hurdles remain: establishing reliable, global supply chains of hydrogen fuel at scale and demonstrating effective technologies for its use, particularly in power generation.

Enabling hydrogen power generation

For both challenges, Kawasaki Heavy Industries (Kawasaki), a Japanese technology company and founding member of the Hydrogen Council, has leading-edge answers.

At the beginning of 2022, the world’s first liquefied hydrogen carrier successfully transported liquefied hydrogen across continents. The carrier, named Suiso Frontier, was built by Kawasaki as a member of the CO2-free Hydrogen Supply-chain Technology Research Association (HySTRA).

The ship’s return voyage from Hastings in Victoria, Australia, to Kobe in Japan was supported by the Japanese government and a consortium of companies backed by the Australian government. This groundbreaking inaugural journey was part of a pilot project to build a liquefied hydrogen supply chain, including large-scale production and transport for global markets.

Kawasaki’s goal is to demonstrate the technical feasibility of such a supply chain by the late 2020s and aim for commercialisation around 2030.

Besides carriers, the company is developing liquefiers, loading systems, storage tanks and other technologies for producing, transporting and storing hydrogen. It is also pioneering new technologies to generate electricity and heat from hydrogen fuel.

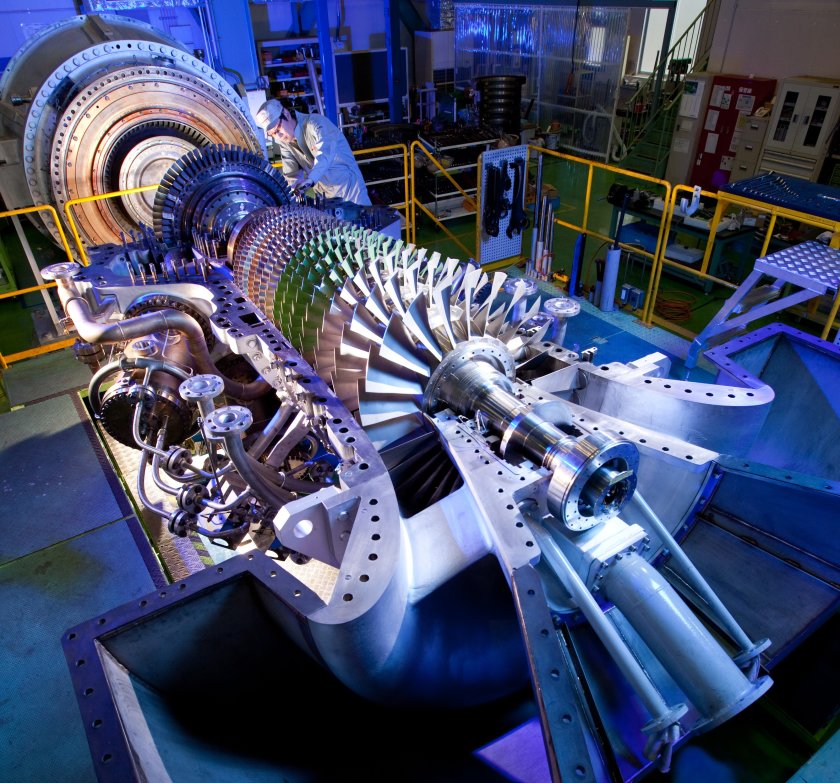

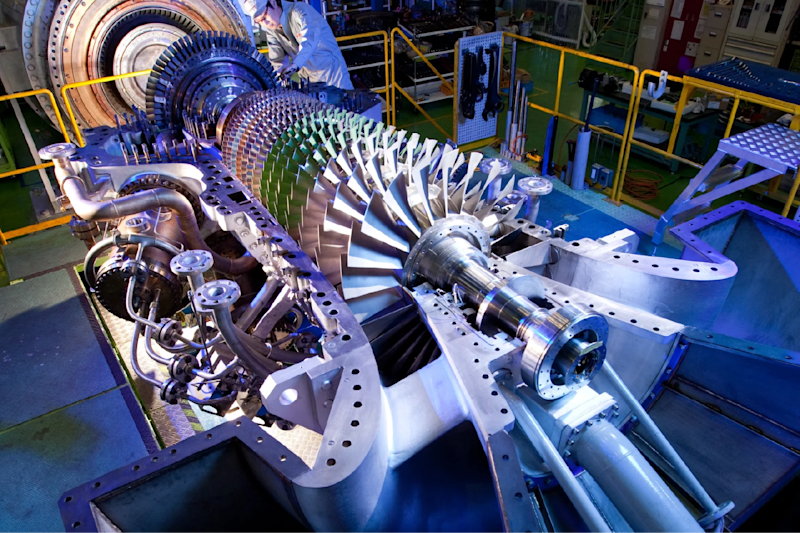

The company realised early on the importance of using hydrogen and has been developing hydrogen gas turbine technology. For this reason, it has developed two main strengths. Firstly, it has moved ahead of other companies in the low nitrous oxide (NOx) technology used in hydrogen-powered gas turbines. Secondly, it has pioneered technology that allows it to flexibly change the mixing ratio of hydrogen and natural gas, allowing users to adjust according to the amount of hydrogen available.

Kawasaki successfully demonstrated these two unique technologies in the world's first operation of a 1MW-class gas turbine cogeneration system using 100 per cent hydrogen in the urban environment of Kobe, Japan, in 2018. The company conducted the demonstration as a NEDO (New Energy and Industrial Technology Development Organization) grant project.

The next step is to demonstrate the feasibility of hydrogen power generation at scale. In 2026, Kawasaki plans to start a demonstration test of a 30MW-class hydrogen power plant at a site in Lingen, Germany, in partnership with European energy giant RWE. The experiment will demonstrate the feasibility of the mixed combustion of hydrogen and natural gas fuel as well as combustion using only hydrogen fuel. Kawasaki has been conducting investigations for the demonstration project with support from NEDO.

“RWE acknowledges Kawasaki’s leading role in the hydrogen business across major areas, including hydrogen combustion, shipping and processing,” says Gregor Herklotz, senior asset developer, RWE Supply & Trading GmbH. “Past operation successes of its combustion technology and the teams behind it make Kawasaki a very attractive partner for us.” Reflecting such successes, Kawasaki was awarded the German Gas Industry Innovation Award in 2022 for its state-of-the-art Micromix H2-capable combustion system.

Kawasaki chose to partner with RWE because it has a strong interest in the hydrogen business, including the commercialisation of hydrogen gas turbine power generation technology, in line with Kawasaki’s business aims and strategy. Over the years, the firm has established a reliable partnership with RWE through its Germany-based energy business subsidiary.

Supplying hydrogen gas turbines

Kawasaki believes its hydrogen gas turbines are suitable for powering electricity grids for in-house industrial use. In the first case, hydrogen can be used as an energy source when renewable energy sources stop generating power, such as at night or when the wind stops. In the second case, hydrogen gas turbines can provide large energy savings in cogeneration use by supplying thermoelectricity as a distributed power source.

Another potential market is for Kawasaki to retrofit existing Kawasaki-manufactured gas turbines with a hydrogen combustor, enabling the turbines to burn mixtures of up to 30 per cent hydrogen and natural gas. Around 650 gas turbines, used mainly for factories and power plants worldwide, can be modified this way. The company estimates that the cost of converting an existing gas turbine generation facility to a hydrogen fuel-fired facility will be about 25 per cent of installing a new one.

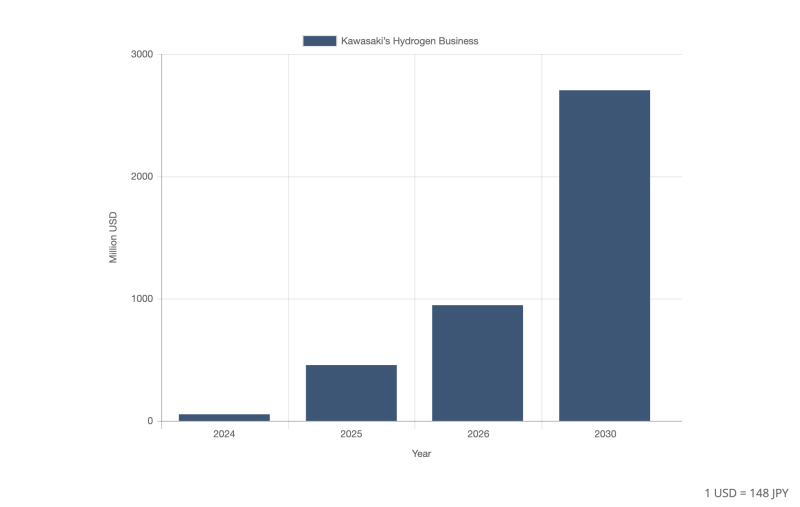

Kawasaki is developing its capabilities across the supply chain. The company is expecting to generate ¥68bn ($459mn) in 2025, ¥140bn ($945mn) in 2026 and ¥400bn ($2.7bn) by 2030 from its hydrogen business.

By mid-century, the company hopes to capture ¥2tn ($13.5bn) of an estimated ¥12tn ($81bn) in demand for hydrogen chain-related technologies.

Longstanding vision for a hydrogen future

The ongoing disruptions to energy markets have been accompanied by increased enquiries from potential customers about Kawasaki’s hydrogen technologies, including its power generation solutions. As the world accelerates efforts towards decarbonising economies, the company’s longstanding vision for carbon neutrality with hydrogen remains unchanged.

Kawasaki believes it can contribute to the realisation of a hydrogen society by creating a liquefied hydrogen supply chain and stably transporting hydrogen in large quantities. From here, it says its next step is to promote the use of hydrogen gas turbine power generation made in its company in Europe, followed by gradual deployment in other parts of the world.

The company says its ultimate aim is to contribute to the realisation of a carbon-neutral society around the world.

This content was paid for and produced by Kawasaki Heavy Industries in partnership with the Commercial Department of the Financial Times.