Zoom into Details behind the ALICE SYSTEM―Design Concept Committed to Reality Part 1: ALICE Rail designed with Real-World Railway Standards in Mind

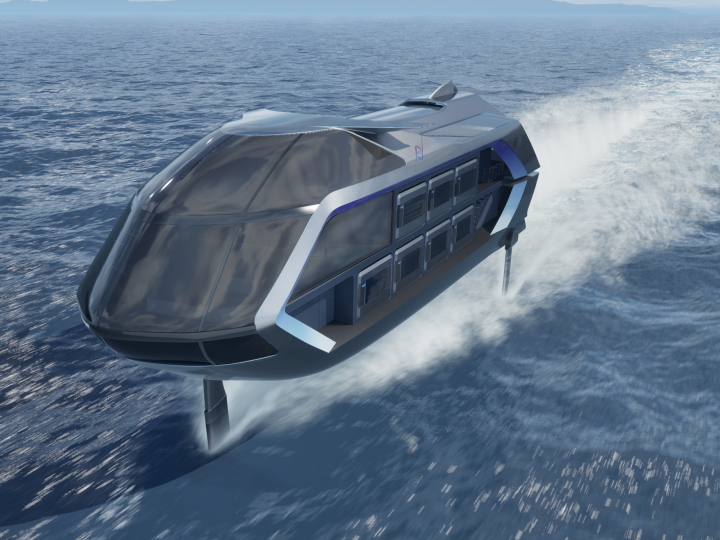

ALICE SYSTEM, showcased at Expo 2025 Osaka, Kansai, Japan, is a futuristic public transportation system model developed by Kawasaki leveraging its robust technological capacity and expertise related to land, sea and air transportation. The overall concept of this system centers on docking for connecting multiple mobility functions, and its design is characterized by a strong commitment to realism.

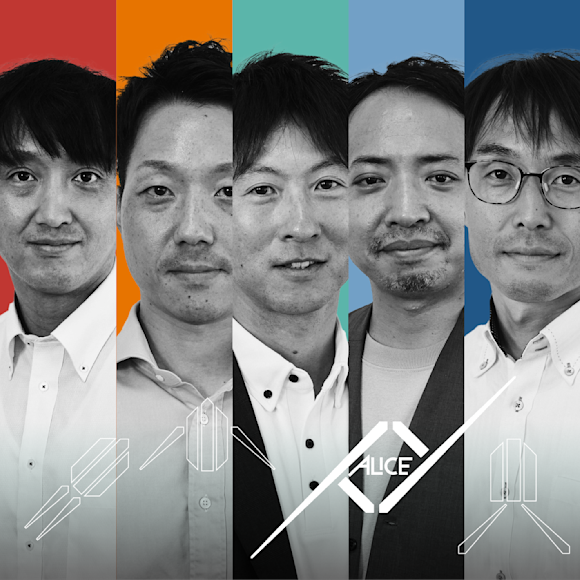

What drives Kawasaki, an expert in comprehensive mobility engineering with deep expertise across the three major mass transportation modes, to pursue development and design concepts for the ALICE SYSTEM that are grounded in realism ? This serial article presents a behind-the-scenes story of the project based on insights given by five engineers in charge of the design for each of the mobility elements of ALICE SYSMEM―ALICE Rail (train), ALICE Aircraft and ALICE Ship―as well as Yoshimoto Matsuda, Executive Officer who played a key role in the design and development of the ALICE SYSTEM’s power generation unit. In Part 1 of this five-part series, we explore ALICE Rail.

Utilize the present capabilities to create a new future

Design thoughts behind ALICE SYSTEM

As a comprehensive mobility engineering expert in land, sea, and air transportation, Kawasaki is knowledgeable about the advantages and limitations of current public transportation systems. New future mobility system plans need to be compatible with existing infrastructure functions for railways, airports, seaports and the like. If they are not, such plans, no matter how ingenious, will be nothing more than a pipe dream, given that the estimated costs for product development and social implementation are likely to become prohibitively high. Noting this, the ALICE SYSTEM project team began to explore approaches to achieving future public transportation systems that delivers an unprecedented level of convenience and comfort, while making effective use of current technologies. To achieve this, the team incorporated a wide range of design concepts aimed at ensuring a smooth and practical transition to future mobility.

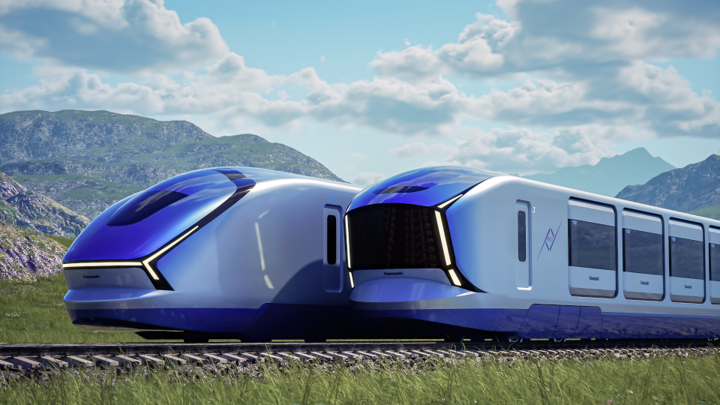

ALICE Rail Based on Existing Railway Gauge and Train Car Specifications

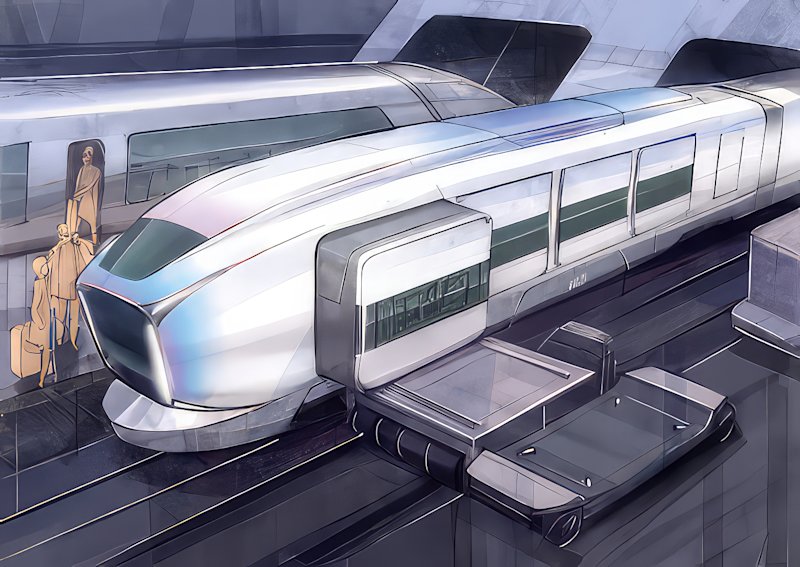

ALICE Rail is a next-generation railway system designed to deliver privacy and comfort comparable to that of private jets and cruisers. This system features spacious passenger cabins, each accommodating up to four passengers, docked directly onto the train. It also includes a dedicated dining car and lounge area exclusively for cabin passengers, while comfort is carefully considered throughout the shared spaces on board. Dimensional designs are based on full-size Shinkansen specifications, and it is powered by a hydrogen-powered engine system that does not emit CO2.

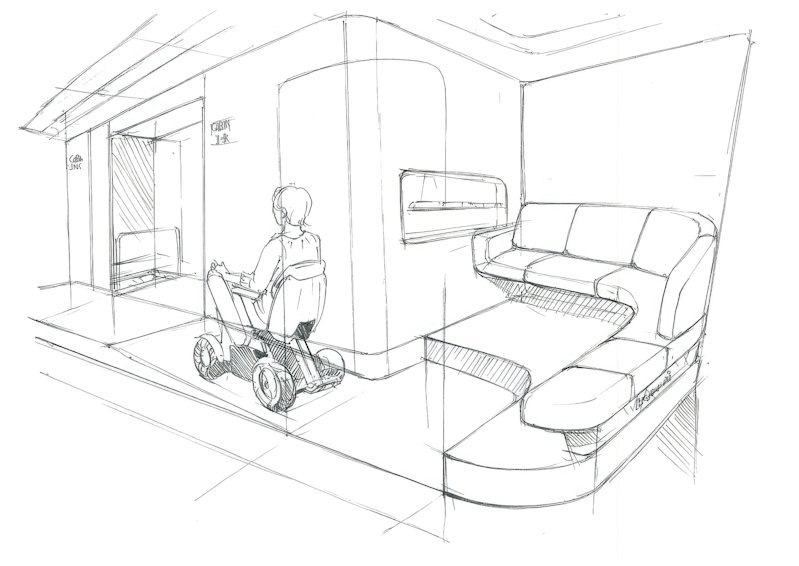

The design process for the entire ALICE SYSTEM began with ALICE Rail. To ensure compatibility with existing rail tracks and train car specifications, the team started by determining the width of the aisle in the train. The goal was to allow passengers to move comfortably, even when the cabins are at maximum capacity. A 90cm aisle width was chosen to ensure that wheelchair users could pass through without difficulty. Based on this standard, the cabin specifications, including dimensions and capacity were determined.

We adopted a barrier-free design for the train car after gathering feedback from wheelchair users working at Kawasaki Heartful Service*. Their insights were instrumental in determining key accessibility features, including aisle width, entrance dimensions and routing to and from the dining car and restrooms to ensure easy accessibility. One notable example is the sunken kitchen in the dining car, which minimizes discomfort for wheelchair users when ordering meals and enables comfortable interaction with staff at eye level.

*Kawasaki Heartful Service Co., Ltd.: a special purpose subsidiary of Kawasaki Heavy Industries, which promotes employment of people with disabilities.

A key consideration in designing the cabin docking process was minimizing interference with conventional railway operations. One solution was to design the cabin interface so that docking occurs from the side of ALICE Rail opposite the platform, allowing general passengers to board and disembark from the platform as usual without disruption.

We are considering the possibility of separating train stations for cabin docking from those for use by general passengers. Since the docking station does not necessarily have to be nearest or most frequently used station by cabin users, we could select less busy stations with simpler layouts and renovate to serve as dedicated to cabin docking facilities. This might be a more practical solution.

Kawasaki Railcar Manufacturing Co., Ltd.

Kawasaki Railcar Manufacturing Co., Ltd.

To be continued in Part 2: ALICE Aircraft Featuring New-concept Lounge Areas