NICHIJO’s Rotary Snowplow: Achieving Excellence in Overcoming the Challenges of Snow

Japan is a country with regions where the world’s heaviest snowfalls are seen. To protect the lives of people in these regions, many snow-removal technologies have been developed. NICHIJO CORPORATION, a member of the Kawasaki Group, has been leading this innovation, and now holds a 70% market share in Japan.

Heavy Snow Regions Account for 51% of Japan’s Landmass

Japan is undoubtedly the snowiest country in the world. According to the Japanese “Act on Special Measures for Heavy Snowfall Areas,” such areas are defined as “regions where snow hampers economic growth and has an adverse effect on the lives of residents.” Of all regions in Japan, 51% falls into this category, affecting about 20 million people.

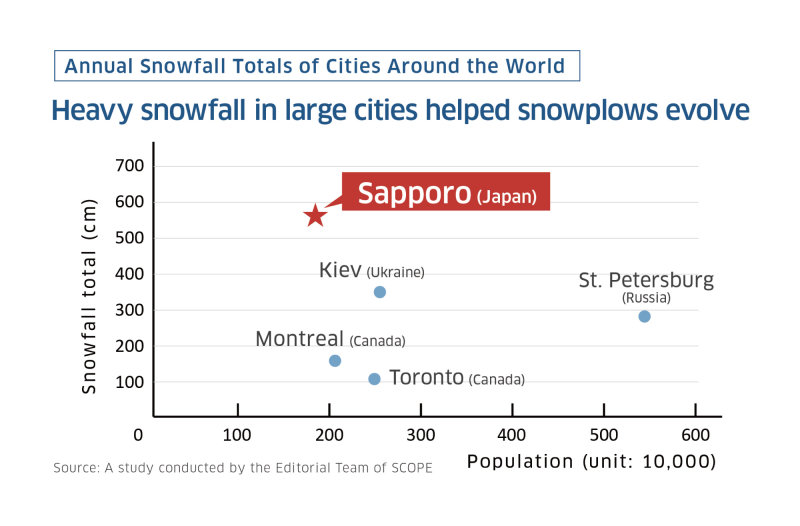

Compared to most other snowy regions of the world, those in Japan are characterized by high population density. Of all cities with a population exceeding 1 million, Sapporo (population: 2 million) tops the list, recording six meters of snow annually ― far more than the two meters of Canada's Montreal, which ranks second in this category.

Snowplowing is a two-phase process: primary removal, in which a road grader (with a scraper-shaped blade) pushes the snow to one side, and secondary removal, in which a rotary snowplow blows the snow into the distance. A rotary snowplow is operated by a pair of people ― the driver and the operator ― who are greatly respected as the operation requires a very high level of skill and experience. The operator uses seven or eight different levers to control the angle of the snow-removal unit and the direction in which the snow is blown. The driver is responsible for controlling the snowplow’s engine output and speed, according to the hardness and depth of the snow. They must function as a single unit.

NICHIJO holds a 70% domestic market share in rotary snowplows. Since its inception 60 years ago, NICHIJO (formerly known as Nihon Josetsuki Seisakusho) has been tackling the challenges of snow removal in Japan, and as such is essentially the source of Japan’s rotary snowplow history. The company has developed and manufactured a variety of snowplows ― from a compact version for sidewalks to a medium-sized one for narrow streets to a giant machine for expressways and airport runways.

The snowplowing industry is not immune to workforce shortages due to an aging population. As the industry leader, NICHIJO is focusing on developing labor-saving technologies to accommodate such emerging societal needs.

A Finished-Product Maker Meeting Demanding Requirements by Manufacturing Parts In-House

NICHIJO first entered the rotary snowplow market at the request of an operator of a mining railway that ran through an area in western Hokkaido with dense snowfall. NICHIJO quickly developed a proprietary auger ― a rotating helical collector installed at the front of a snowplow ― that performed as well as Swiss-made augers, which the company had initially tried to duplicate but failed because of patent issues.

In 1959, NICHIJO successfully launched the first domestically-produced rotary snowplow locomotive, which led the Hokkaido Regional Development Bureau to ask NICHIJO to develop a large vehicular snowplow ― the rotary snowplow ― which was named the “Hydraulic Torque Converter Rotary (HTR).” Since then, “HTR” has been included in the model names of all rotary snowplows manufactured by NICHIJO.

The HTR408 is the latest, most advanced model, dedicated to expressways and major roadways in areas with heavy snowfall. With a dimension of 9 m (length) x 2.6 m (width) x 3.5 m (height), the machine is equipped with a 480 HP engine which powers the 2.6 m x 1.75 m snow-removal unit and the snowblower that ejects the snow from the mouth of its chute to a designated distance of 20 m, 30 m, or 45 m. Its maximum removal capacity per hour is 4,200 tons, the equivalent of a 10-t truck removing 420 loads per hour or one 10-t-truckful of snow every nine seconds.

This model boasts various measures for uninterrupted operation, such as an auger equipped with a device to prevent it from taking up tire chain waste on the road. The center pin that connects the vehicle and the snow-removal unit can articulate to facilitate the turning of the snowplow at narrow intersections.

When the editorial team of SCOPE visited NICHIJO’s Inaho and Akebono Plants in Teine Ward, Sapporo City, in mid-September 2019, production was peaking in preparation for the coming snow season. Masaki Ohta, General Manager of the Engineering Division commented, “In Japan, heavy snowfalls are often seen in big cities where there are many narrow streets, and yet we have a distinctive aesthetic that snow removal must be done in a beautiful manner. Because of these unique requirements, specialized technologies were developed to meet them. These are also reasons why it has been difficult for non-Japanese snowplow manufacturers to enter the Japanese market.”

These distinctive “aesthetics of snow removal” require that the auger be able to take in snow effectively and that the snowblower chute be maneuverable, with the blowing distance easy to change. The auger’s optimally formed helical blade is the fruit of research spanning more than half a century, and it is now capable of handling both light and heavy snow.

In order to achieve the high level of performance required for effective snowplowing, parts are manufactured in-house, except for a few such as engines and tires, making NICHIJO a finished-product manufacturer with high insourcing capability. At the division where the auger’s helical blade is produced, a special device is used to machine thick steel plates into a helical shape and the blade is welded onto the unit. The chassis of the vehicle is also assembled in-house and even the driver's seat mat is manufactured by the company.

President of NICHIJO, Takayoshi Suzuki, explains, “Our customers, including local governments and operators of expressways, have a critical mission to fulfill. In order to meet their sophisticated level of technological requirements, we must work closely with them to develop products which meet their needs and accumulate the necessary expertise. The in-house manufacturing of parts was essential to meeting those needs.”

Developing Automatic Control Technology to Accommodate Labor Shortages

Although we cannot predict when snow will start to fall, when it does, snow removal must be carried out without delay. As a manufacturer with the predominant market share in Japan, NICHIJO runs a network of 80 distributors, to which spare parts are shipped from headquarters all year round, in order to offer 24/7 after-sales services. However, the aging of snowplow operators and an impending shortage of personnel is a challenge at the customer end.

Experience and skill are required for both drivers and operators, but an increasingly lower number of people are willing to assume these posts. The declining operator population suggests that the safety of local populations that had been achieved by snow removal is already being compromised.

To remedy the situation, Ohta says NICHIJO has been developing various technologies to make snow removal easier. For example, now an intuitively operable joystick can run the snowplow, which previously required seven or eight levers. Other innovations include an automated speed control system which adjusts the speed when the load on the snowplow changes due to variations in depth or hardness of snow, and a monitoring/control system that notifies operators of a problem and automatically displays the location and a description.

Ohta comments, “But to fundamentally resolve workforce shortages due to a declining birthrate and an aging population, it is imperative that we establish a technology to achieve autonomous operations.” To that end, NICHIJO has already embarked on a project utilizing GPS data from the quasi-zenith satellite system “MICHIBIKI” to automatically control snow blowing positions based on a concept jointly-developed with the Hokkaido Regional Development Bureau, to which prototypes have been delivered.

The effectiveness of automated snow blowing was proven in a verification demonstration conducted in spring 2019 at Shiretoko Pass, and the Bureau plans to conduct another test in 2020 to verify whether or not GPS can control the entire function of a snow-removal unit to project the snow onto an exact, pre-designated spot.

Ohta adds, “Achieving a single-operator rotary snowplow should contribute significantly to offsetting labor shortages. But to develop a control technology in-house, not only for the mechanical aspect of the snowplow but also the operating programs, is a daunting undertaking and requires an expansion of our design department.”

Aiming to Produce Products that Best Meet Customers’ Needs: Evolving Technological Development at NICHIJO

With the objective of achieving greater ease of operation and reducing labor, NICHIJO developed a monitoring system by which indoor staff are able to check, control, and record ― in real time ― information being transmitted from snowplows in the field. This system is also useful for responding expeditiously to failures and for recovery efforts

An intuitively-operable stick for controlling a snowplow which offers responsive maneuverability (for medium- to large-size snowplows). Before, users had to manipulate seven or eight levers in order to operate a snowplow

Partnering with Customers to Achieve More Sophisticated Technology

In regard to NICHIJO’s approach to product development, Makoto Okada, General Manager of the Corporate Planning and Control Division, comments, “One of the features of our snowplows is their customizability. Our sales reps therefore have interviews and discussions with customers to fully understand their needs and offer products that best meet their requirements.”

In some cases, the snow-removal unit is replaced with another device to increase the operating ratio of the vehicle. For example, during summer, attachments can be substituted, such as cutting blades for clearing roadside grasses or pumps for draining water in flooded areas. Okada adds, “Such examples demonstrate the high applicability and versatility of rotary snowplows to power various types of equipment.”

In 2011, NICHIJO launched a hybrid rotary snowplow but it did not sell well because of its high price tag resulting from the use of a costly battery. However, when a prefecture-

wide blackout occurred in the fall of 2018, following the Hokkaido Eastern Iburi Earthquake, this rotary snowplow could have served as an uninterruptible power source (UPS). Had the earthquake occurred in the winter, people’s lives could have been endangered.

Okada comments, “Considering the critical nature of the mission entrusted to public service agencies, hybrid snowplows are useful as they can generate power using diesel fuel and function as a high-output UPS. But first we must create a business model for them to be used as snowplows. We’d like to contribute to improving the living environment for local communities by providing superior products that reflect our technological prowess. To that end, we plan to focus on autonomous operation, automatic control, and reduced maintenance costs through utilization of AI (Artificial Intelligence) and IoT (Internet of Things).”

To overcome the challenges of snow, NICHIJO is committed to achieving technological innovations and transforming its business models ― all to make living with snow safe and secure.

Expanding NICHIJO’s Brand Presence by Developing Diverse Products Utilizing Our Superior Know-How Cultivated in the North

To sustain its snowplow business, NICHOJO is planning to realize a broader scope of business through its diversification strategy. One of our areas of focus is specialized vehicles, including transporters which transport heavy goods, train cars and dump trucks to carry iron ore to steel mills, etc.

The technologies we have developed for rotary snowplows can be applied extensively to these vehicles, and the technologies are sophisticated enough to meet our customers’ rigorous requirements. Plans to expand our capability in automatic control technology and other mechatronics areas should also benefit our specialized vehicle business.

NICHIJO CORPORATION

Protecting Lifeline Infrastructure and Otherwise

Contributing to Local Communities

NICHIJO developed a rotary snowplow locomotive at a time when graders and bulldozers were the only snowplowing equipment available. When it was completed, the engineers decided to mount the newly-developed product on a truck chassis and created the first rotary snowplow. This achievement was made possible because of our customers’ deep confidence in our development capability, which enabled us to collaborate with them to develop these snowplows and protect the lives of people in snowy regions.

We underwent difficult times when the business environment deteriorated due to curtailed funding for public works and the introduction of tougher environmental standards, but that did not affect the confidence the customers had placed in us. Thanks to their support, we now hold a 70% domestic market share, achieved through the annual manufacture and shipping of about 200 units of rotary snowplows.

NICHIJO and another manufacturer are the only two players left in the rotary snowplow market today. Further increasing our market share takes improvement in our competitive advantage, but it also entails heavier social responsibility, as snowplows are used by customers tasked with highly-critical public missions. We are also committed to developing innovative technologies to meet emerging needs such as the replacement of old snowplows, labor shortages, the aging of operators, and other issues arising at point of use.

My responsibility as management leader is to expand our scope of business by leveraging our snowplow technologies. In addition to an excellent lineup of rotary snowplows, our product portfolio includes snowplow locomotives, antifreeze spraying vehicles,and specialized vehicles such as transporters. We plan to launch a more solid business model so as to achieve stability in our snowplow business, which should help us contribute more to overcoming the challenges of snow.

I am encouraged by the increasing number of young people who express their desire to join NICHIJO in order to work at a local company and serve local communities through locally-developed technologies. I also feel responsible for leading the company to become a great contributor to local communities.

Engineering Division

NICHIJO CORPORATION

Corporate Planning and Control Division

NICHIJO CORPORATION