High-Performance, Twin-Engine, Multipurpose Helicopter BK117 D-3

Medical service helicopters rush to transport victims in an emergency. Firefighting helicopters are dispatched to fire and disaster sites any time of day or night. The BK117 multipurpose helicopter series, which plays an active role in a variety of areas, was the first of its kind in Japan produced by Kawasaki in 1982. The technology incorporated in the D-3, the latest model in the series, is revealed.

Significantly Increased Useful Load and Reduced Vibration Achieved

The BK117 D-3 is the latest model of the BK117 Series of multipurpose helicopters, jointly developed by Kawasaki and Airbus Helicopters. The D-3 has recently been awarded a type certificate by the European Aviation Safety Agency (EASA) and the first domestically-produced helicopter is expected to be ready for delivery in the spring of 2021.

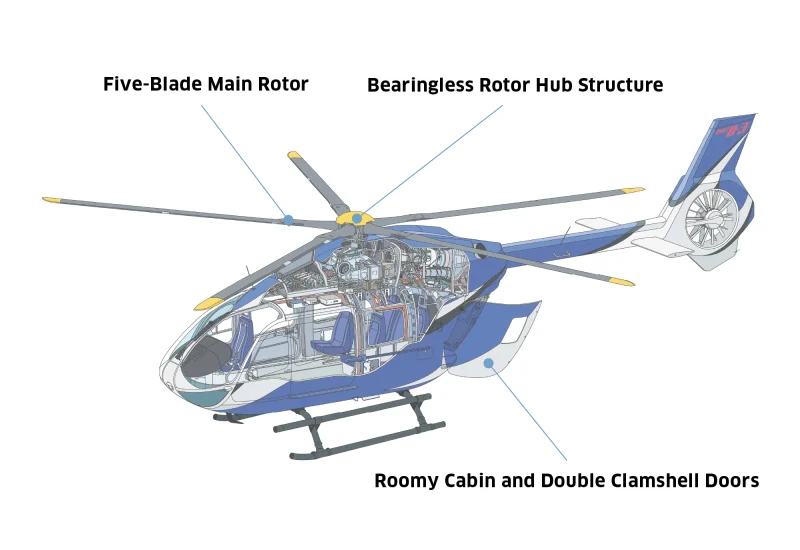

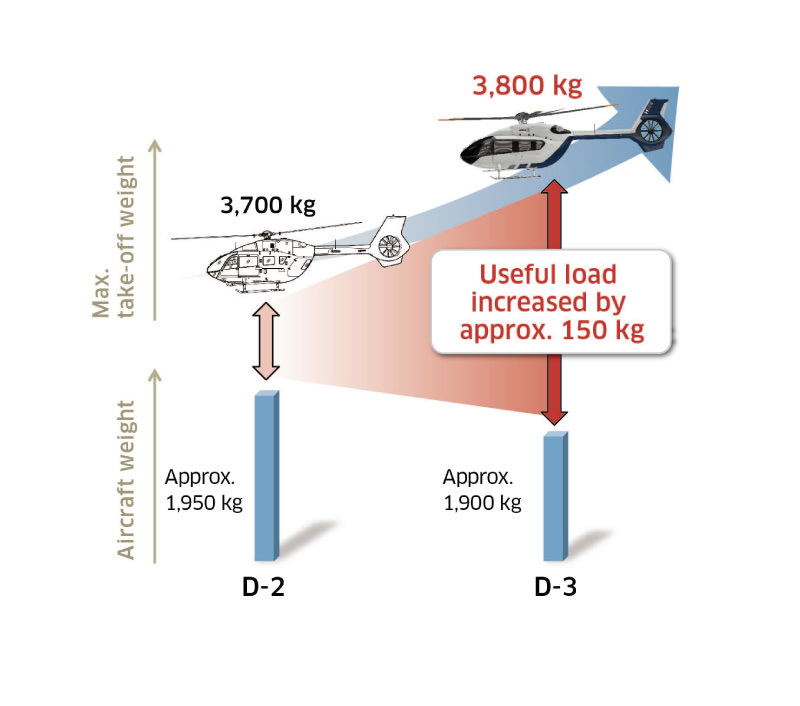

While the D-3 inherits excellent high-altitude hovering performance and state-of-the-art avionics (electronics) from the previous model, the D-2, the following functionality improvements have been made: 1) An increase in the number of main rotor blades from four to five, 2) Adoption of a bearingless design for the rotor hub, and 3) An increase of 150 kg in the useful load.

The five-blade main rotor achieves reduced vibration of the aircraft, and the simpler, bearingless hub structure allows for longer intervals between inspections/maintenance. This design has also reduced the aircraft weight by almost 50 kg, which, coupled with a 100 kg increase in the maximum take-off weight, has increased the helicopter’s useful load by 150 kg. Such improvements translate into an increased capacity for transporting people and goods, resulting in significant benefits to operators and customers.

Since delivery of the first BK117 in 1983, the rotorcraft has undergone a series of upgrades, making it a product of high technological value and reliability that can be utilized in a wide range of missions, including emergency medical services (EMS), firefighting, and disaster relief. This medium-size, twin-engine BK117 Series has become a global best-seller, with deliveries made by Airbus and Kawasaki combined surpassing 1,600 units.

Five-Blade Main Rotor Reduces Vibrations and Improves Flying Comfort

The revolution of rotor blades creates distinctive vibrations, with the principal vibration frequency of the helicopter per revolution determined by the number of blades.

In addition to adopting a new rotor system, the increase in the number of blades from four to five — thus changing the vibration frequency — has optimized the helicopter’s vibration and attained improved flying comfort. Pilots also give high ratings to its maneuverability.

The five-blade feature, which comes from foundational research done by Airbus, contributes greatly to reducing total weight. Thanks to this feature, the D-3 is free of the anti-vibration device which is found under the cabin floor of the D-2.

Foldable Rotor Blades for Compact Storage

Currently under development is a new optional feature that allows for the five rotor blades to be folded, so that the helicopter's width and length can be reduced to fit in a small hanger.

Simple Yet Robust Bearingless Rotor Hub Structure Enables Easy Maintenance

In designing the BK117, bearings were adopted for the rotor hub mechanism, which rotates the main rotor by transmitting to it the power of the engine. The lubrication provided by these bearings allows the angle of the rotor blades to change, in order to generate aerodynamic lift. However, the D-3 adopted a bearingless rotor hub, reducing the number of parts while achieving reduced vibrations with its five-blade rotor design.

With this new design, a soft but high-strength structural element called the “composite flexbeam” is installed at the inner end of each rotor blade. This element allows the angle of the rotor blades to change as needed to generate aerodynamic lift.

With no bearings, the hub became structurally simpler, requiring no lubrication system or disassembly process for maintenance. This helps extend the intervals between inspections and maintenance, as well as reducing the helicopter's weight. Another Kawasaki helicopter which has already adopted the bearingless design is the OH-1.

BK117 Series’s Signature Roomy Cabin and Double Clamshell Doors

The optimized structure of the frame and skin panel allows for seamless configuration of the cabin and cargo room, realizing a fully-flat floor and a roomy passenger space. The electrical wiring, oil pipes, etc. are installed behind a thin wall - a prominent design technique of Kawasaki. Easy access to the cabin through the double clamshell doors at the rear is a feature highly rated by EMS helicopter operators.

Useful Load Increased by 150 kg

The D-3 has achieved an increased maximum take-off weight (the weight allowable for flying, including the aircraft itself, passengers, and other items) of about 100 kg. In addition, its total weight was reduced by about 50 kg, thanks to adoption of the new hub design, resulting in an overall increase of 150 kg in useful load.

This improvement enables the D-3 to rescue more people during disaster relief, and to carry more medical equipment and healthcare professionals on EMS missions. It also allows for more fuel to be loaded, providing operators with greater operational flexibility.

Future Helicopter Project Section

Future Helicopter Project Planning Department

Helicopter Project Group

Aerospace Systems Company

Kawasaki Heavy Industries, Ltd.

Future Helicopter Project Planning Department

Helicopter Project Group

Aerospace Systems Company

Kawasaki Heavy Industries, Ltd.