A shift from road transport to other means — a so-called modal shift – has been gaining momentum in recent years, and locomotives are top of the list as beneficiaries of this shift. A pioneer of domestically-produced locomotives, Kawasaki’s journey in locomotive manufacturing is the history of the Japanese locomotive itself, which began in the early 20th century with the introduction of steam locomotives.

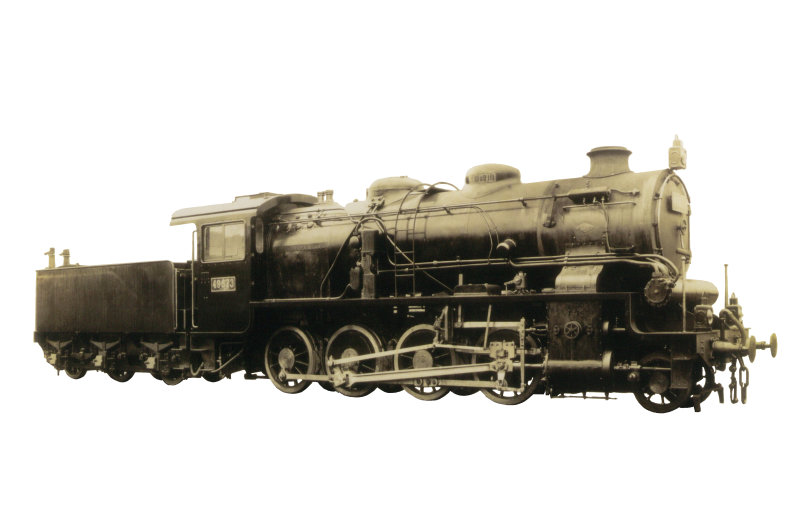

Type 9600

A standard steam locomotive used for freight in the first half of the Taisho Era (1912-1926). Nicknamed “Kyu-Roku” (Nine-Six), it was mass-produced and used across the country until the use of steam locomotives terminated in the Showa Era. By 1925, Kawasaki had manufactured 686 of the 784 domestically-produced Kyu-Rokus.

Type EF65

A direct-current electric locomotive which became the standard for electric locomotives in Japan. The high-speed 500 series which was added to this family of industry-leading locomotives had a maximum speed of 110 km/h and was equipped with an electromagnetic brake command device.

Type DE10

A mass-produced switcher locomotive equipped with a 1,250 hp engine and a set of switchable low/high hydraulic transmissions (an improved version of its predecessor, the DD51). Compared to preceding switchers, the DE10 has a smaller axial load, making it possible for it to haul cars on branch lines, yet the weight was increased so that it achieves higher switching performance.

Type DF200

A new type of diesel-electric locomotive which operates on non-electrified sections of rail in Hokkaido Prefecture. Its power output is 1.5 times that of conventional types, enabling it to operate at high speed. In addition to cold and snow resistance features, the DF200 employs a GPS-based acceleration detection device — the first ever for locomotives in Japan.

Type EF210

Developed to replace the Type EF65, which was the most mass-produced locomotive for Japanese National Railways (predecessor of the Japan Railway companies), the EF210 is used mainly for hauling container cars that can withstand high-speed operation on the Tokaido and Sanyo Lines. With a power output of 3,390 kW and maximum speed of 110 km/h, this locomotive is capable of hauling 1,300 t of goods.

When government-run factories began producing locomotives in the early 20th century, they had no choice but to source many of the parts from other countries. An ever-increasing amount of import expenses was a headache for the government, which was curbing imports at the time, so a 100% domestically-produced locomotive was an imperative. In response, Kawasaki and Kisha Seizo Co., Ltd. committed themselves to tackling the challenge.

However, with the merger of the two companies in 1972, the main role of manufacturing locomotives domestically was entrusted to Kawasaki. With Hyogo Works as its manufacturing site, by December 2018, Kawasaki had reached a milestone of 5,000 Japan-made units.Various types of locomotives, both large and small, have been designed in order to haul cargo and passenger cars of different weights. These efforts at accommodating individual needs helped Kawasaki advance in the production of more sophisticated, high-performing locomotives.

With respect to commercial steam locomotives, their production in Japan ended in 1953 with the “25tC for Kawasaki Seitetsu” as the last type to be produced, heralding the era of electric locomotives. Because Japan is a country with many steep mountains, electric locomotives are expected to have the power to climb steep slopes and the capability of operating at high speed, on par with passenger trains, so that they do not disrupt passenger train schedules.

A number of challenging situations compelled Kawasaki to develop many advanced features.These progressive steps culminated in the EF210, an advanced locomotive, one of which was crowned with the honor of being the 5,000th unit, and which serves as the main freighter for Japan Freight Railway Company which has received over 100 of the Kawasaki-made units. The EF210 is capable of hauling goods weighing more than 1,000 t at 100 km/h. Watching this locomotive zooming by, spectators undoubtedly realize that the technologies behind it are extremely sophisticated.

A shift from road transport to other means — a so-called modal shift – has been gaining momentum in recent years, and locomotives are top of the list as beneficiaries of this shift.

A pioneer of domestically-produced locomotives, Kawasaki’s journey in locomotive manufacturing is the history of the Japanese locomotive itself, which began in the early 20th century with the introduction of steam locomotives.