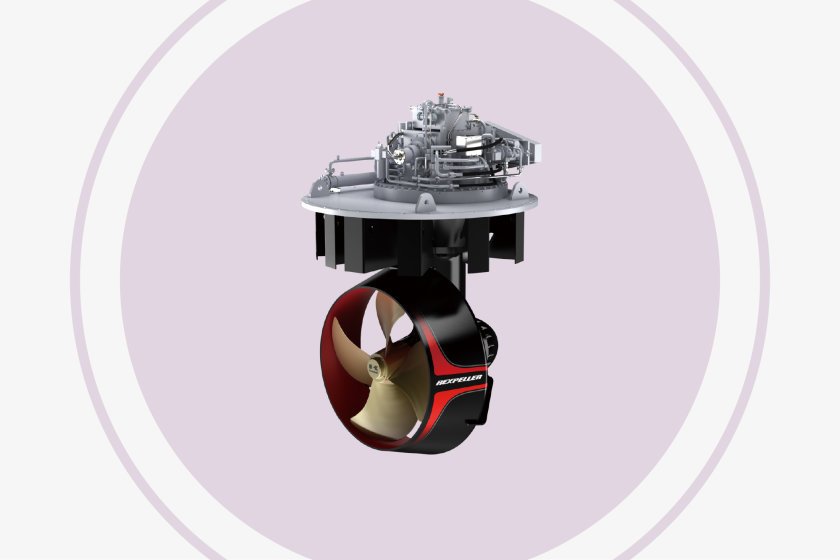

The Rexpeller is an azimuth thruster that enables marine vessels to have precise and agile maneuverability and accurate positioning capability, which are essential requirements for operation in severe nautical conditions. Thirty-five years after receiving its first order, Kawasaki is ready to make a further leap forward in the evolution of the Rexpeller.

The Rexpeller is an azimuth thruster which rotates the propeller 360-degrees around the vertical axis so the unit generates thrust in any direction horizontally, to act as propulsor and rudder. Tugboats, offshore supply vessels, drill ships, and cable-layers are major beneficiaries, thanks to its superior maneuverability.

Since 1983, when Kawasaki commenced production of the Rexpeller, more than 1,000 units have been delivered. Culmination of Kawasaki’s comprehensive technologies such as fluid-dynamics for marine propellers, hydraulic technology for accurate control, and reduction gears technology for reliable torque transmission are fully incorporated in the design and are working all over the world.

Kawasaki has an excellent delivery record for the Rexpellers for vessels engaged in offshore oil and gas development, such as drillships that use them in the drilling of oil and gas wells, shuttle tankers that transport oil and gas mined from petroleum wells, and platform supply vessels that transport goods to offshore platforms. The growth in market share achieved by Kawasaki is attributable not only to its highly reliable equipment, which operates stably in harsh environments caused by strong winds and tidal currents, but also to Kawasaki’s ability to accommodate the individual requirements of its clients, and achieve made-to-order customization.

In 2018, Kawasaki launched the E-series Rexpeller into the market, and has already been awarded orders for four units. Deemed a model with the potential to become a new international best-seller, high expectations are placed on the E-series as a driver of increased sales.

First order for the Rexpeller received

The first order was for a tugboat owned by a Japanese company. Production of Rexpellers started at Akashi Works (then Akashi Minami Works, in Akashi City, Hyogo Prefecture), and its all-in-one structure, arranging the clutch and hydraulic machinery on the platform (foundation), drew much public attention as the first such design in Japan.

First delivery of the A-series Rexpeller made

Launch of the A-series dramatically extended the market share of Kawasaki, even though Kawasaki was the last to enter the market for azimuth thrusters in Japan. The A-series pulled a trigger that led to a variety of vessels equipping themselves with azimuth thrusters, other than tugboats.

Six units of a Rexpeller model that was one of the world’s then-largest azimuth thrusters were delivered for the Chikyu, a deep-sea scientific drilling vessel

The Chikyu was the first vessel in history which could drill into the earth’s mantle. Using six units of the coordinated Rexpellers, the Chikyu is able to remain in a specified position in the ocean while using an excavation drill to drill the seabed, without any anchors and/or mooring lines. Such stability of position is possible for as long as a year, even under challenging conditions where wind speeds of up to 23 m/s, waves 4.5 m-high, and currents moving at 3-4 knots are seen.

First order for the retractable Rexpeller for shuttle tankers received

A shuttle tanker is a vessel used for transportation of oil from an offshore production platform to an onshore oil stockpile base. The Rexpeller, which provides omnidirectional thrust, is instrumental in offshore operations, as they require accurate maintenance of positions. The retractable Rexpeller can be retracted into the hull by hydraulic means, allowing the vessel to sail at high speed by reducing hull resistance during transportation.

New factory completed to increase production capability

For extended demand of azimuth thrusters in the growing oil and gas related offshore development market, a new factory was built at Harima Works (in Kako County, Hyogo Prefecture) and production commenced.

First order received for the E-series Rexpeller – our newly-developed azimuth thruster

The E-series, which offers energy savings through improvements of propulsion efficiency, ease of onboard maintenance, and environmentally friendly performance, was launched. Four units were ordered, which will be installed onto tugboats to be operated by China's Port of Tianjin, and the operation will start from the latter half of 2018.

Kawasaki has an excellent delivery record for the Rexpellers for vessels engaged in offshore oil and gas development, such as drillships that use them in the drilling of oil and gas wells, shuttle tankers that transport oil and gas mined from petroleum wells, and platform supply vessels that transport goods to offshore platforms. The growth in market share achieved by Kawasaki is attributable not only to its highly reliable equipment, which operates stably in harsh environments caused by strong winds and tidal currents, but also to Kawasaki’s ability to accommodate the individual requirements of its clients, and achieve made-to-order customization.

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment