Centrifugal Compressor “KM Comp” Underpins Vietnam’s Energy Infrastructure and Transition to Hydrogen Energy

Thanh Hoa Province in Vietnam is home to the largest oil refinery in the country — the Nghi Son Refinery, which plays a pivotal role in securing Vietnam’s energy supply. At this refinery, Kawasaki’s centrifugal compressor “KM Comp” is used in the oil refining process. This story features the way in which KM Comp is contributing to the support of Vietnam’s energy infrastructure and the role this product is expected to play in Kawasaki’s initiatives toward achieving a hydrogen-based society.

Nghi Son Refinery — Vietnam’s Largest

The Nghi Son Refinery is the most cutting-edge refinery in Vietnam and also the largest, in terms of size and production capacity. It alone supplies about 40% of the nation’s total petroleum products, thereby making a significant contribution to the economy, the lives of the population, and society as a whole. Speaking on the important role the refinery plays in Vietnam, Hiroaki Honjo, Department Manager of the Administration and Corporate Affairs Department at Nghi Son Refinery and Petrochemical LLC (NSRP) — the operator of the refinery — comments, “Its presence is significant, and the refinery is contributing greatly to the overall development of the country.”

KM Comp’s Pivotal Role at the Nghi Son Refinery

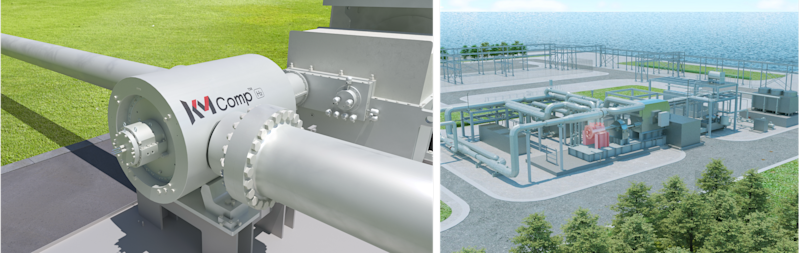

Removing sulfur compounds from crude oil is one of the processes required for refining oil. This desulfurization is achieved via a catalytic reaction between crude oil and catalysts in a highly pressurized hydrogen gas environment, with the KM Comp supplying and circulating the pressurized hydrogen gas. Because failure of a compressor immediately halts oil production, KM Comp is designed with a very high level of durability which achieves minimized downtime due to malfunctions, thereby meeting the needs of customers who consider its reliability to be a crucial feature of centrifugal compressors.

Giving KM Comp a high-performance rating, Nguyen Huu Cuong of the Operations Division at NSRP says, “The KM Comp guarantees outstanding energy efficiency, leading to reduced steam consumption and minimized operational costs. Additionally, its reliable and durable operation enhances overall operational efficiency. This compressor stands out for its ease of operation, control, and maintenance.”

KM Comp’s impressive performance in international markets

A compressor is a machine that compresses fluids such as gases or steam in order to achieve a required pressure and volume. At a refinery, compressors are used for various purposes, such as compressing and separating gases and supplying process gases. The use of compressors significantly increases the efficiency of energy use and improves productivity.

KM Comp is equipped with a rotor powered by a driver (electric motor/gas turbine/steam turbine). Gas, passing through impellers which are attached to the rotor, is progressively pressurized by centrifugal force and then discharged at a higher pressure from the compressor outlet. Notable features of a centrifugal compressor include efficient compression and large-volume fluid processing, as well as quiet operation with reduced vibration.

Since the initial delivery of a KM Comp in the 1970s, the number of deliveries — mainly to India and Southeast Asian countries — has considerably increased. Notably, it is worth highlighting that KM Comp plays an active role in offshore natural gas plants. Compressors at offshore facilities are likely to have erosion or internal corrosion because treated gas near the wellhead contains many impurities. In addition, the volume and pressure of gas change over time. Despite these severe circumstances, compressors, which are the most critical machines in a plant, are required to achieve a high uptime rate without shutdown, considering that it is difficult for specialized maintenance workers to access these plants frequently due to their location. Meeting these stringent requirements, KM Comp was adopted by the Nghi Son Refinery to support its 24/7 operation, which is conducted with the mission of meeting Vietnam’s energy needs.

Global trend toward decarbonization leads to high expectation for hydrogen

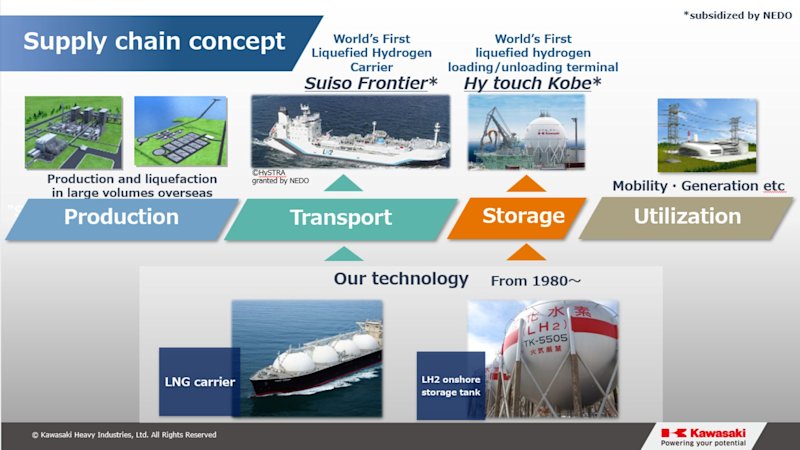

Oil and natural gas are highly-consumed energy sources in many countries and regions, and KM Comp is in operation worldwide at this very moment. However, as climate change and environmental issues have become globally-shared challenges, hydrogen — which produces no CO2 when combusted — is expected to play a vital role as an energy carrier. All divisions at Kawasaki Heavy Industries have been making united efforts to establish a global supply chain of liquefied hydrogen with the goal of realizing a hydrogen-based society.

To accommodate the global trend toward increasing hydrogen use, KM Comp is currently undergoing various upgrades to achieve compatibility with hydrogen. Hydrogen gas delivered through pipelines is challenging to pressurize by centrifugal force because of its lightness. To do so uses approximately 10 times the energy needed for pressuring compared to natural gas. To achieve the pressure ratio expected to be required for hydrogen gas in various fields in the future, compressors must have extremely sophisticated technologies such as a multi-stage structure, high rotational speed, and high pressure.

Combining its hydrogen and KM Comp know-how accumulated over the last 40 years, Kawasaki has been developing the “KM Comp-H2,” which will be able to handle 100% hydrogen gas. Construction of a demonstration plant for the KM Comp-H2 began in February 2025, at its Harima Works. The KM Comp-H₂ will be responsible for the process of boosting the pressure of the hydrogen gas used as the refrigerant for feed hydrogen gas — the raw material for liquefied hydrogen. The knowledge and data gained through the development of this machine will also be applied to the development of centrifugal hydrogen compressors for hydrogen supply pipelines, which are expected to be in greater demand in conjunction with the expansion of hydrogen energy.

Confident of the potential of the hydrogen-compatible KM Comp-H2, Yui Tanaka of the Land Machinery Sales Department of Kawasaki’s Energy Solution & Marine Engineering Company says, “KHI has manufactured, delivered, and strongly supported our customers all over the world, including NSRP. At the same time, Kawasaki also expects to contribute to realizing a next-generation decarbonized society by developing our new type of KM Comp for hydrogen.”

Kawasaki’s contribution to future society

The time-tested performance of KM Comp has been making 24/7 operations possible at the Nghi Son Refinery, which underpins the energy infrastructure of Vietnam. The compressor’s proven durability and reliability, which have withstood harsh environments in Vietnam and other countries, should make KM Comp applicable to hydrogen — the energy of the future. As previously mentioned, new, hydrogen-compatible models are being developed to accommodate the global trend toward carbon neutrality.

When hydrogen becomes the most widespread energy carrier of the future, the new KM Comp-H2 will be working diligently for the world’s network of pipelines and contributing to the realization of a sustainable society.