Kawasaki’s Electro-hydraulic Steering Gear

An electro-hydraulic steering gear controls a ship’s rudder, which is the ship’s turning mechanism.Kawasaki boasts the world’s largest market share in this sector, with their products installed on a cumulative total of 20,000 vessels, reflecting the deep confidence customers have placed in its product.

Such a large number of deliveries is the result of Kawasaki’s commitment to resolving the challenges presented by each successive era, resulting in superior steering gears being adopted by vessels of the largest class built during that period.

Development of the electro-hydraulic steering gear was a technological revolution that changed the landscape of the sector, which had previously been dominated by steam-pressure-driven gears. To capitalize on this innovative technology, Kawasaki decided to partner with the U.K.’s John Hastie & Co. Ltd. and the Hele-Shaw Company in 1916, to utilize the Hele-Shaw type electro-hydraulic steering gear in its products.

The first vessel equipped with this steering gear was the merchant ship Florida Maru, completed in 1925, followed by the cruiser Kinugasa in 1926. (Kawasaki also began manufacturing Hele-Shaw pumps in 1924.) At that time, the most popular hydraulic power source for steering gears was the electric-motor-driven pump, and it remained so for a long time as it was possible to change the discharge rate as well as the direction of the oil flow.

In 1964, Kawasaki started to manufacture large "BV Type" electro-hydraulic steering gears, using the B Series axial piston pumps of the German firm Bruninghaus, with whom Kawasaki entered into a technological tie-up. This steering gear was adopted by successive mega tankers, with each one breaking the world record for capacity. In the process, Kawasaki continued upgrading the product in terms of reliability, durability, accuracy, and torque characteristic suitable for actual rudder load ― the mandatory features of steering gear.

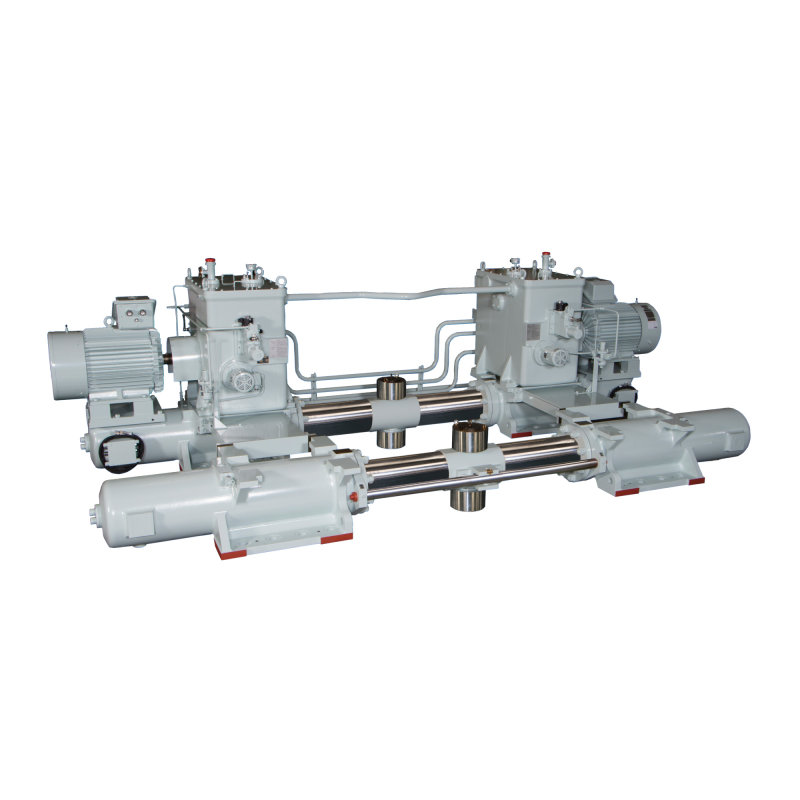

Because pumps are key to operating electro-hydraulic steering gears, Kawasaki developed the “LV Type” steering gear in 1987, for which their proprietary L Series bent-axis-type axial piston pump was adopted. This was another technological innovation in the marine equipment sector.

The company’s journey of innovation continued: in 2016, it launched the “LV Type 20 Series” which achieved higher hydraulic pressure and lighter weight compared to the LV Series, while ensuring equivalent reliability.

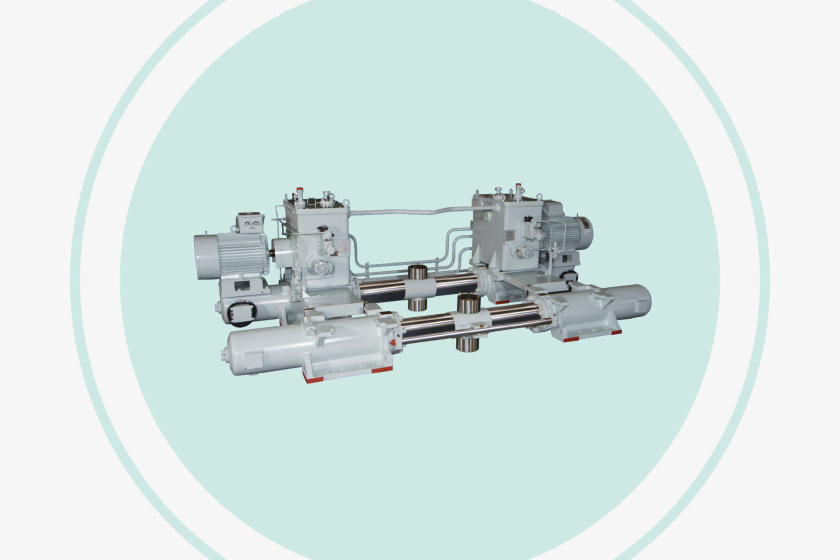

Hele-Shaw Type

The first domestically-produced electro-hydraulic steering gear using technology obtained through partnerships was installed on the merchant ship Florida Maru, followed by the cruiser Kinugasa in 1926, and the aircraft carrier Hiyo in 1942. After WWII, Kawasaki also developed a compact Hele-Shaw steering gear for fishing boats, contributing to the modernization of fisheries in Japan.

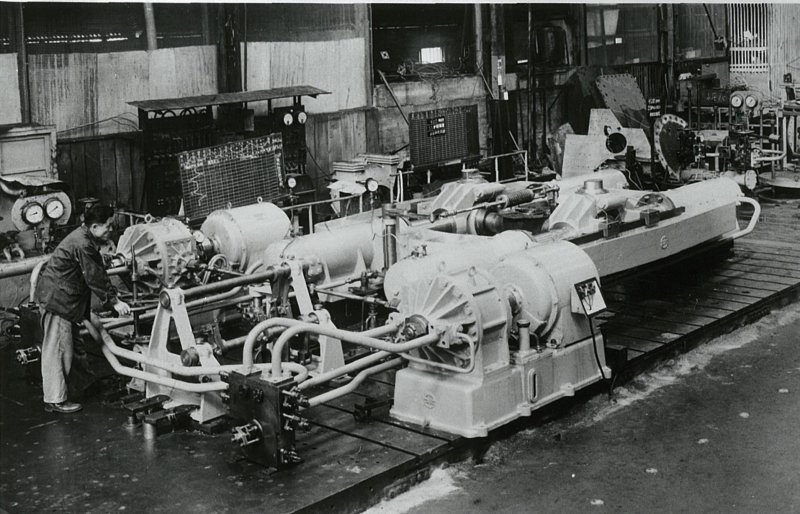

BV Type

The FD-85P, with its BV axial piston pump developed by the German firm Bruninghaus, was installed on the tanker Tenryugawa Maru in 1964, closing out the era in which large Hele-Shaw pumps had typically been used. This innovation achieved a significant cost reduction through increased hydraulic pressure and rotational speed not possible with the Hele-Shaw pumps. Many mega tankers broke capacity records by adopting the BV Type, and these development efforts helped Kawasaki strengthen its technological foundation.

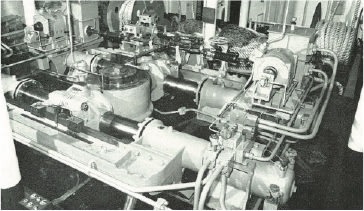

LV Type

Kawasaki developed the “LV Type” large steering gear using its L Series bent-axis-type axial piston pump and other proprietary technologies. Adoption of the high-pressure, long-lasting L Series pump dramatically increased the steering gear’s hydraulic pressure and durability, as well as its response capability and steering angle accuracy achieved via the development of a continuous control system. These features worked together to maximize the energy-saving autopilot’s performance.

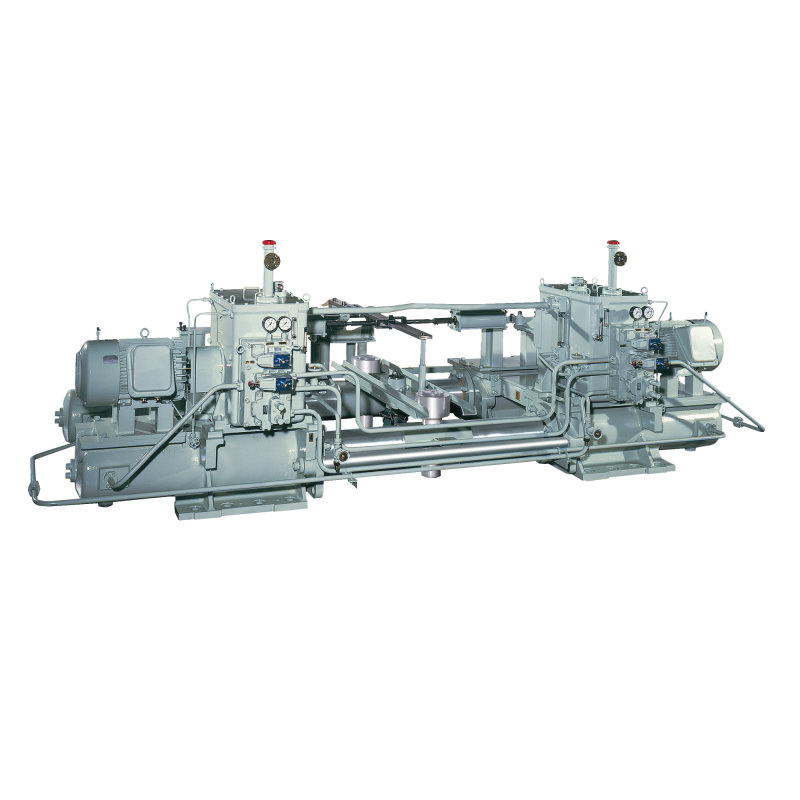

LV Type 20 Series

This series, with its redesigned steering gear actuator which realized higher hydraulic pressure, reduced weight, and a more compact size than the LV Type, provides enhanced competitiveness while maintaining the Type’s reliability. Compared to the initial model of the Hele-Shaw pump developed nearly a century ago, power density per unit weight has increased six-fold.

Furthermore, in 2018, in conjunction with Mitsui O.S.K. Lines, Kawasaki launched a project to develop steering gear technologies which would provide energy-saving operations and failure prediction resulting from new sensing capabilities and big data analysis. Kawasaki is sure to lead the industry in the coming era, too, when steering gears will be equipped with intelligent features.