Liquefied petroleum gas (LPG) carriers transport LPG composed primarily of propane and butane, which are byproducts of petroleum refining and natural gas processing. Looking at the history of LPG carriers, one can tell that Kawasaki has always been a pioneer in innovation.

Building a vessel for transporting LPG or liquefied natural gas (LNG) requires sophisticated cryogenic technologies, which include material selection for the tanks, structural considerations, thermal insulation, and treatment of boil-off gas. Such expertise is considered one of the barometers for judging the level of a manufacturer’s shipbuilding technology.

The first Kawasaki-developed LPG carrier, BRIDGESTONE MARU NO.5, was built in 1969 with a structurally novel tank called a “semi-membrane tank.” Installed in the insulated double hull, this cubic tank was made of thin (8-10 mm) low-temperature-service steel plates and had no structural members. This ingenious design resulted in Kawasaki winning The Okochi Memorial Prize, which is considered the highest honor in manufacturing. Since then, the semi-membrane tank has become one of the global standards of cargo tanks.

Moving further, Kawasaki embarked on another innovative challenge in the 1990s. With an eye toward improvements in safety, analytical accuracy for stress on tank materials was improved, and to shorten shipbuilding time, the company switched its design approach to that of an independent tank system. With this tank system, independent cargo tanks are installed in the hold and the load of the cargo is supported by the tank itself. In 2003, Kawasaki adopted a new bow shape, the “SEA-Arrow (Sharp Entrance Angle bow as an Arrow),” and led its LPG carriers into the third generation. The new bow shape reduced wave resistance by half and significantly improved the ship’s propulsive performance.

Today, Kawasaki is going even further, having developed the next-generation LPG-powered LPG carrier, and implemented robust new marketing strategies.

BRIDGESTONE MARU NO.5( - 1983)

This vessel was the first to apply the semi-membrane tank system which was jointly developed by Kawasaki and Bridgestone Liquefied Gas Co., Ltd. (the company’s name at that time). In this tank system, the tank is self-supporting when empty, but when fully loaded, it expands as a result of hydraulic pressure and its load becomes supported by the ship’s hull-a unique design which became one of the world’s leading tank systems. Eight ships have been built by Kawasaki.

PACIFIC HARMONY(- 2003)

Improvements in materials used for cargo tanks and in accuracy of stress analysis made the development of the independent tank system possible. This tank system allows the tank itself to support the cargo’s liquid load. Adoption of the new tank system also proved effective in shortening the shipbuilding period, and the first vessel equipped with the system, Pacific Harmony, was completed in just 19 months. The vessel also achieved an impressive cargo capacity of 84,000 m3. Kawasaki has built 23 ships in the past dozen or so years.

CRYSTAL MARINE( - 2019)

The next innovation added to the independent tank system, and which resulted in our next-generation LPG carrier, was a new bow shape called the SEA-Arrow. SEA-Arrow halved the bow wave resistance and decreased the main engine horsepower by 6-10% compared to conventional LPG carriers moving at the same speed. Characterized by the replacement of the mainstream bulbous shape with an innovative design, SEA-Arrow achieved outstanding propulsive performance. The number of LPG carriers built with SEA-Arrow has reached 24 and is still increasing.

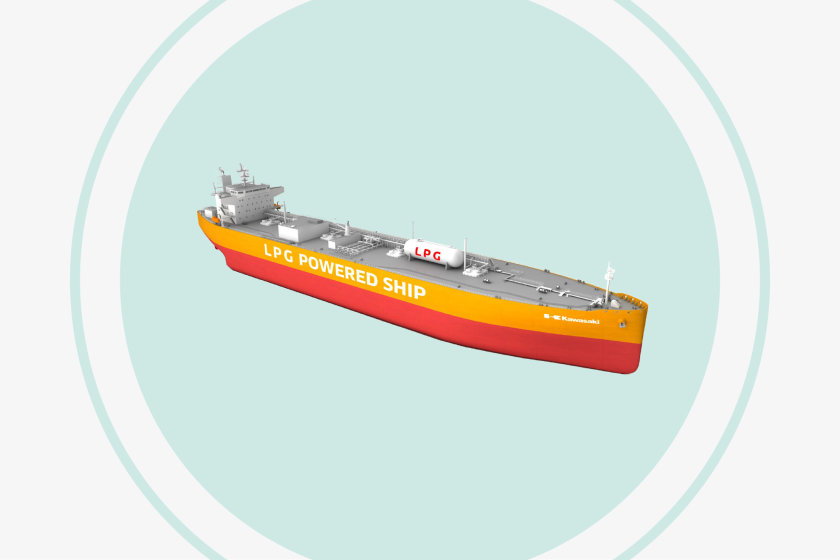

LPG-powerd LPG carrier

The next-generation LPG carrier will be designed to achieve large-capacity transport using LPG as fuel, while fulfilling various marine transport environmental rules and regulations. It should also be able to enter LPG terminals used by existing carriers. Kawasaki has already developed the specifications and basic design, and when completed, the ship will be a showcase of Kawasaki’s shipbuilding expertise. Robust marketing activities for the new ship are already underway.

The next-generation LPG carrier was designed to reduce emissions of nitrogen oxides (NOx) and sulphur oxides (SOx) in marine transport and complies with updated international transport rules and regulations that demand a higher level of safety. In addition, despite the installation of larger tanks, it can enter the same LPG terminals as existing carriers without compromising on capacity-a feature that shippers expected of the new vessel. Kawasaki stays ahead of its competitors by pioneering innovation. This fundamental approach defines our strength in shipbuilding.