For an Evolved State of Coexistence Between Humans and Robots Attempts by Future Lab HANEDA

On April 20, 2022, Kawasaki launched the proof-of-concept facility for robotics, Future Lab HANEDA. Different from conventional disclosed installations, this is a place of open innovation where the public, researchers, and business visitors communicate with, learn, use, and promote the integrated use and evolution of robots. Kawasaki has taken on the new challenge in order to address social issues with robot technology. The aims and beliefs of the company are reported from the actual site.

Demonstration Experiment at the AI_SCAPE Robot Café

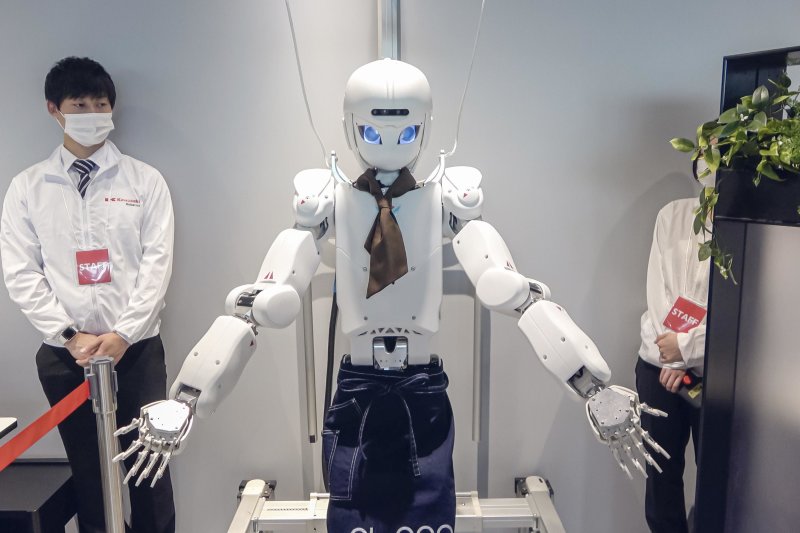

Nyokkey is still a little clumsy, and the robot’s operation is far from smooth. However, when Nyokkey holds a tray with its hand, gently places it on the table, and greets the customer with “Here are your orders. Enjoy,” diners tend to smile and clap their hands. People automatically smile when faced with technologies that offer a sense of the future. ―― This is a scene at AI_SCAPE, the robot restaurant located at Future Lab HANEDA.

Noboru Takagi, general manager of the Robot Business Division, Precision Machinery & Robot Company of Kawasaki, explains,

“AI_SCAPE offers a space for conducting proof-of-concept tests where robots welcome and serve customers as cooks, waiters, and drink servers. AI_SCAPE forms the core of Future Lab HANEDA together with YouComeLab, which is a facility for the research and development of robots by venture-backed companies and research institutions.”

All of the freezer, microwave oven, heating water bath, and trays used in AI_SCAPE are commercial ones used in ordinary restaurants, and the robots must use and control them precisely. What problems may occur and what challenges can arise if humans do not assist the robots? The purpose of the demonstration experiments is for identification and improvement of any issues.

All Tasks Carried Out by Robot Operation

Three models of six original Kawasaki robots are in use at AI_SCAPE: RS007L, duAro2, and Nyokkey. Although the machines to transfer trays from cooking robots to serving ones as a substitute for a belt conveyor to connect the processes are by a different manufacturer now, Kawasaki robots will carry out all operations in the future.

● Cook: RS007L

(1) Grasp frozen rice or bread, place it in the microwave oven, and heat it

(2) Heat boil-in-the-bag food, such as curry and soup, in a water bath, open the bag, and place the food in a bowl

(3) Remove salad from the refrigerator and place it with cutlery onto a tray

These tasks are assigned to the respective robots. One pushes the proper defrost button for rice, bread, and pasta depending on the menu order. Another provides a really fine performance of shaking the food bag after water-bath heating to remove hot water and moving to pour the food from the opened bag into a bowl.

● Drink server: duAro2

Swinging its arms to exhibit skills in the drink area, the duAro2, a dual-armed SCARA robot, shows that it can coexist and collaborate with humans. Each of the two arms is capable of lifting an object up to 3 kg in weight, and as an industrial robot, the duAro2 is dedicated to handling electric and electronic components. At AI_SCAPE, it sets a cap on the automatic beverage machine, pushes a menu button, and serves drinks to a customer.

● Waiter: Nyokkey

Nyokkey can receive a tray with dishes, serve the food, clear the dishes after a meal, and clean the table, as well as show a variety of facial expressions on its liquid-crystal display. The two arms have six axes each for movement, a grip-type hand at the end of each arm, and four wheels for moving: the front two are motored and the rear two are omni wheels. Two 600-watt lithium-ion batteries power the robot so there is no need to replace them during the lunch or dinner operating hours.

“Though it displays only predetermined expressions now, we contemplate modifications to change the look in response to a guest waving a hand.”

Ability to Cover a Variety of Situations Using Robots

The longest step in cooking is heating boil-in-the-bag food in a water bath, which takes about seven minutes after a meal is ordered. If there are a series of subsequent orders, the waiting time for the heating step is decreased, and the orders are ready at intervals of a couple minutes.

“Industrial robots are fastened in exclusively designed areas and work according to the production plan with 100% precision. However, service robots are supposed to be capable of coping with accidents. Immediacy and response to uncertainties are strengths of humans, and we plan to increase the engineering elements to give robots the capability of responding the same as we do. The use of artificial intelligence is considered a matter of course, and we are thinking about cooperating with startups to develop such software.”

YouComeLab Accelerates Open Innovation

Future Lab HANEDA has another installation and mission that should be noted. YouComeLab was established next to AI_SCAPE with the intention of sharing the use of the robots. While AI_SCAPE is for the public, YouComeLab is for Kawasaki’s customers and partners, startups, and academia.

First, Future Lab HANEDA is located at the west end of Runway B of Haneda Airport and the international and domestic terminals are close by. In addition, Ota Ward, where the airport is located, is home to many manufacturers.

“Through this convenience, YouComeLab was established so that many companies and researchers become aware of Kawasaki’s robotic expertise and use this site for demonstration tests. We have loaned robots for the development of robot operation software, and we are now targeting open innovation in maturing software and related technologies based at YouComeLab. Of course, we also encourage engineers from Kawasaki.”

First Unification of Development and Use

The plan is to develop and use not only industrial robots but also a wide variety of dual-armed SCARA robots and humanoid robots like Kaleido and RHP Friends. Then, YouComeLab will be a place of learning for those unfamiliar with robots, as well as a place for business matching, in addition to the development and proof-of-concept tests.

The development and use of robots have been different in the conventional robot industry of Japan. Future Lab HANEDA was established to unify the two with the expectation of promoting the use of robots in domains with little robotization.

“At both AI_SCAPE and YouComeLab, we dare to show the unfinished state, or the present limits, of robots to all visitors and other companies. Though it demands that engineers be determined to accept harsh criticism, this is exactly what is required to evolve robots.”

As robots become more familiar, ideas for applications will develop. Seeing Nyokkey, you might think it is incompetent because of its limited capabilities. However, those who have followed it since the beginning would be surprised, “I’m moved to see it has reached this level. How about trying this motion next?”

Initial Step of Evolution: Let People See What Robots Cannot Do

Kawasaki now runs two robot-related centers: Kawasaki Robostage in Odaiba, Tokyo, to show what robots can do for the public, and Nishi-Kobe Showroom for companies that plan to introduce industrial robots. Additionally, Future Lab HANEDA offers completely different characteristics.

People meet robots, and the use of robots develops through trial and error to address social issues. One should not be embarrassed about their limitations but identify what they cannot do and obtain ideas for tomorrow. Takagi talks about the future vision as follows:

“Our ambition is to someday convert the food courts at major airports and malls into robot restaurants. We will specify the challenges to overcome for that objective at AI_SCAPE and begin improvements. You should leave what robots can do to the robots and do what only humankind can address. I would be happy if you could experience how people and robots coexist at the robotics facilities of Kawasaki.”

Opening Future Lab HANEDA implies the arrival of a new era in Japanese robot history.

Director of Robotics Policy Office

Industrial Machinery Division

Manufacturing Industries Bureau

Ministry of Economy, Trade and Industry

I expect the emergence of robot innovation as the foundation of the resolution of social issues.

While the population is decreasing and developed countries are calling for action with regard to energy savings and automation, the expectations for reliable Japanese robots are increasing. Future Lab HANEDA was opened in such a context. I hope that the facility will further extend the range of robot use.

From my point of view, if people enjoy cooking and serving by robots at AI_SCAPE, they will feel more familiar and attached to robots, which will lead to promoting the spread of robots in a broad area. As YouComeLab serves as an open innovation hub and gathers many people with state-of-the-art technologies and ideas, new projects unique to Japan backed by prosperous robot production will be initiated and help to solve many social issues.

The additional creation of innovation requires connections between people to become fellows, but not in a hierarchical manner, and to use the strengths of each individual. I anticipate that the ideas and expertise of research institutions, companies from different industries, startups, and individuals, in addition to industrial robot technologies accumulated so far, will be assembled, and moreover, made better by listening to the voices of users directly at Future Lab HANEDA, resulting in accelerated innovation.

Access to Future Lab HANEDA

Location

Haneda Innovation City Zone D 2F D2-3 1-1-4, Haneda Airport, Ota-ku, Tokyo

Hours (restaurants and shops)

Lunch: 11:00–14:00 (Last order 13:30)

Dinner: 16:00–19:00 (Last order 18:30)

Closed

Every Wednesday, New Year’s Holidays

*If the Wednesday will be national holiday, we are closed on next day on weekday.

*Since our attribute as demonstration experiment, business hour and closed date might change without notice. Please check before you visit.

Transportation availability

Directly connected to Tenkubashi Station on the Keikyu Airport Line and the Tokyo Monorail Line

Executive Officer

General Manager of Robot Business Division,

Precision Machinery & Robot Company,

Kawasaki Heavy Industries, Ltd.