From Industrial Robots to Humanoid Robots Tomorrow’s Robots Pictured by Kawasaki

Hearing the term “robot,” each person imagines something different. Some people think about human-like androids and others remember the gigantic robots in sci-fi movies. Anyway, the word robot is accompanied by the image of future machines. However, in reality robots have always supported our everyday activities behind the scenes for this half century. Moreover, they will possibly be a closer part of our lives.

Conversion From Industrial to Comprehensive Robot Manufacturer

You may notice that many robot technologies are used around us, including industrial robots, service robots for logistics and medicine, and robot vacuums and household appliances with artificial intelligence (AI) features. This technology is already an essential component of our daily lives and is predicted to make further inroads into our society.

Japan's Robot Strategy, as proposed by the Ministry of Economy, Trade and Industry in 2015, states that Japan should try to become the world’s best showcase for robot use by focusing on the development of robots useful in the fields of manufacturing, services, nursing and medical care, infrastructure and disaster preparedness, construction, and agriculture. In particular, the robot market is expected to grow and even accelerate in the post-COVID-19 era. In order to minimize physical contact between persons, autonomous service robots work in the areas of medicine and security while at industry sites, the reduction in human resources using remote control and collaborative robots is a major issue. In addition, because online shopping is spreading, the logistics industry is about to start making significant changes for the implementation of automatic delivery robots in addition to robots for tasks within warehouses.

The leader in industrial robots, Kawasaki, is going to be reborn as an all-around robot manufacturer. For more than 50 years, Kawasaki has produced working robots for manufacturing tasks during the period of rapid economic growth in Japan. What robots will Kawasaki make with its experience and technological skills? Discover what robots will be like in the new epoch by finding clues from the history of Kawasaki robot production.

Kawasaki, a Pioneer in the History of Industrial Robots in Japan

The history of industrial robots in Japan started with Kawasaki. In 1969, Kawasaki released Kawasaki-Unimate, the first Japan-made industrial robot. At that time, Japan was experiencing rapid economic growth. Gigantic construction projects, including expressways and major office buildings, were established one after another everywhere in the cities, and automobiles rapidly became even more popular. While people were excited during the Izanagi economic boom, industry suffered a serious labor shortage.

Unimate, the world's first industrial robot, was born in such a context. Unimate was made in public in 1962 by the American engineer George C. Devol and Dr. Joseph F. Engelberger, who was an engineer and businessperson regarded as “the Father of Robotics.” The company they formed was called Unimation, and the world's largest automobile manufacturer of that time, General Motors, first employed Unimation’s robots in their plants.

Convinced of the future possibilities of industrial robots, Kawasaki started discussions with Unimation about technological cooperation. The sophisticated engineering of Kawasaki and its excellent expertise in hydraulic components capable of control with micrometer precision was appreciated, and the negotiations with Unimation were successful, finally leading to the conclusion of the technical license agreement in 1968. After one year of technical training in the United States and investigation of a sample machine at a Kawasaki plant in Japan, the Kawasaki-Unimate 2000, the first domestically manufactured industrial robot, was completed.

The automotive industry, where productivity was required to improve, had especially great expectations for the Kawasaki-Unimate, and the units were deployed in the welding process, which was regarded as the so-called 3D jobs (Dull, Dirty and Dangerous). The name Unimate comes from “working mate with universal capability.” Kawasaki independently developed the Kawasaki-Unimate 2630 to reflect customer needs. Many factories then employed this model as new active mates in their manufacturing workplaces.

Kawasaki Robots Overcome Challenges and Change Society

The history of Kawasaki industrial robots is continuously recorded together with the industry after the emergence of the Kawasaki-Unimate. Japanese vehicles stood out during the new period because of the oil crises, and the establishment of the Muskie Act (Clean Air Act) in the United States made people interested in energy-efficient cars and energy savings. While Japanese car manufacturers worked to realize product diversification in response to rapidly changing consumer demand, Kawasaki robots provided support by performing the various operations of welding, handling, and painting. Furthermore, when the tech boom began and the precision equipment market became the most prosperous in the 1990s, Kawasaki developed and manufactured cleanroom robots capable of serving in semiconductor and liquid crystal factories. While the trend for manufacturers to expand business into Asia accelerated around the year 2000, Kawasaki robots spread to every corner of the world. In recent years, they have entered the field of medical care with advanced and more complex diagnostic techniques and treatments. Kawasaki robots have advanced together with the voices of manufacturers and the eras.

In the period of industrialization in the 1960s and the 70s, robots played a part in the so-called 3D jobs of spot welding, painting, and die-casting at automobile factories. The areas of application eventually expanded thanks to the features of high speed, precision, capacity to handle heavy loads, and operation in extreme environments that only robots could achieve. In the late 1990s and afterwards, the digital society brought by progress in information technology sharply increased the demand for cleanroom robots. Using its knowledge and expertise in manufacturing, Kawasaki developed cleanroom robots that could operate in cutting-edge facilities at high precision and low vibration in large work areas in order to essentially eliminate manual operation that had the risks of contamination by dust and dirt and could cope with the rapid increase in the size of wafers and liquid crystal glass. This underpinned the familiarization of PCs and communication devices and thus contributed to the IT revolution.

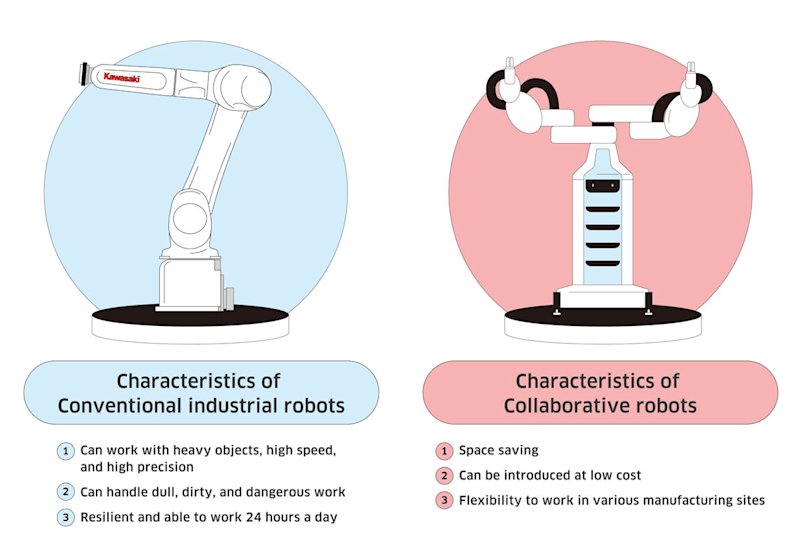

The need for robots increasingly diversified in recent years, and a new era arrived for the use of robots in huge automobile plants and semiconductor facilities but also by putting the right robots in the right place. The type that especially attracts attention now is the collaborative robot.

Intrinsically, machines at production sites, such as industrial robots, have a rigid body and can move fast with strong power, possibly causing severe accidents in the event of a collision with a human. From the safety perspective, protective fences were required between persons and industrial robots. However, with advances in sensor and software technologies, robots and people might work together without barriers if safety measures were implemented. Humankind and artifacts can work side by side, which should lead to the understanding that collaborative robots are our new colleagues.

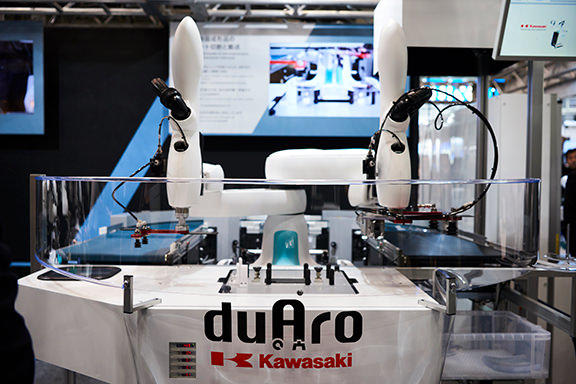

In 2015, Kawasaki released the duAro dual-arm collaborative robots capable of operating in the same workspace as persons. The duAro is an advanced version of the SCARA robots and uses two arms for fine operation on the same line as humans, including dispensing foods into lunchboxes, washing dishes, and assembling precision devices. A variety of workplaces are implementing plans to deploy them as partners, achieving allocation of the right persons and robots in the right place and further improvement of production efficiency. Moreover, Kawasaki developed the remote collaborative robot Successor in 2017. Workers operate the robotic arm remotely, and the robot learns and replicates the delicate, fine control of humans. This feature is expected to transfer expert skills to other engineers and to promote remote work in manufacturing.

The largest market in the robot industry comprises industrial robots. The need for human substitutes as labor in factories has increased since the 1970s, and industrial robots are now installed in many plants. As of 2020, more than 2.7 million industrial robots work throughout the entire world. Because of accurate, efficient production and the competitive product prices required in manufacturing, the need for industrial robots will continue to grow.

Challenges of Kawasaki Robots for a True Universal Society

Robots are not just convenient tools that provide labor in place of humans but are partners in the establishment of a fulfilled society. To realize a universal society with greater safety, more comfort, and more ease of living for everyone, what role will robots play in the near future? Take a view of the society along with the stories of Kawasaki robots.

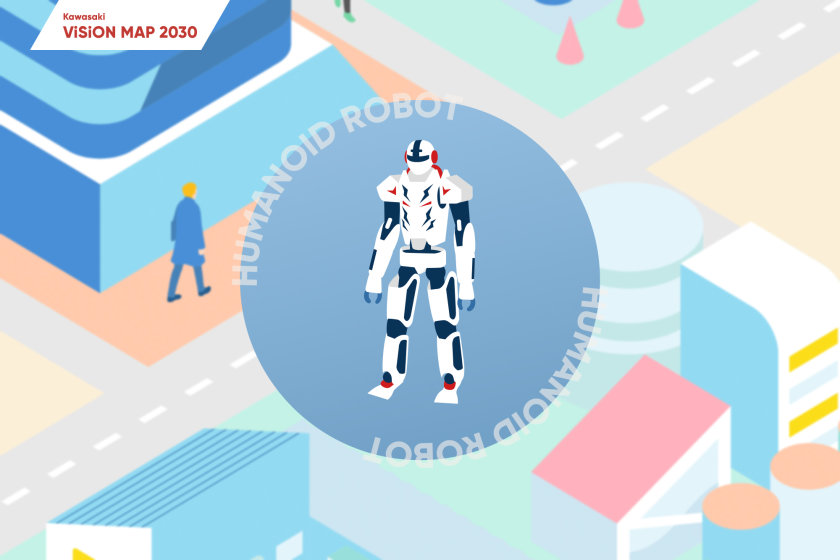

Targeting Practical Use of Humanoid Robots

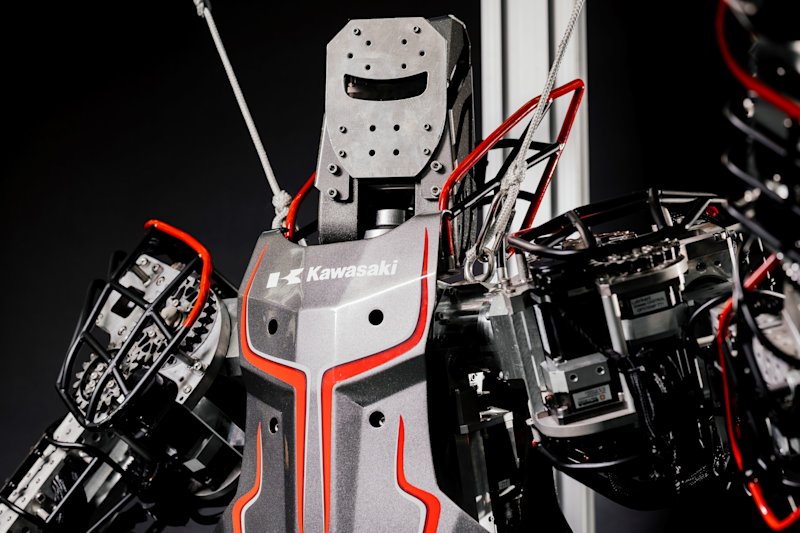

More than a half century has passed since the first Japanese industrial robot was made. Kawasaki has always been the leader in robotics, continuously paying attention to the future of robotics. For example, the Company seriously addressed the human-shaped robot Kaleido for practical use.

Kaleido development started in 2014 based on the concept of a biped humanoid robot that would not break even if it fell. With steady improvement that included a lighter weight body with more durability and integration of the batteries and control units, the series reached its seventh generation in 2021. The most distinguishing idea of this long-established robot manufacturer is to work 24/7 at an accuracy equivalent to or greater than humans. Like quality cars in service for 10 years and 100,000 km or more, robots are being developed for practical use with good durability and maintainability at an economical cost. The objective of Kaleido is to be a real worker, in other words, to help and assist people at dangerous disaster sites and in nursing that requires a physical burden as the ultimate goal.

Emergence of hinotori, a Made-in-Japan Robotic-Assisted Surgery System

Medicaroid was formed as a joint venture of Kawasaki and Sysmex Corporation, which received production and distribution approval for the hinotori™ Surgical Robot System, Japan's first robotic-assisted surgery system, in August 2020. Operations using a robotic-assisted surgery system does not require large incisions in patients, which reduces the physical impact. While the market is dominated by a company from the United States, the well-prepared hinotori endeavors to compete.

Having mustered all robot expertise cultivated over more than a half century, soon after starting development, the hinotori reached the level of dexterity to peel a grape and became a system practically available without fail in clinical use in a short period of about five years. The precise design of the compact body in consideration of the small operating rooms in Japan, high-definition 3D images, the operation cockpit to reduce the fatigue of surgeons, and a double safety system of motion monitoring to prevent the least possible accidents, symbolize the sense of safety and trust typically found in Japanese robots. Furthermore, additional functions are being developed to combine 5G high-speed communication networks, AI, and other next-generation engineering elements with the robotic system. The hinotori continues to evolve for tomorrow where everyone can receive equal quality healthcare services.

Use of Robot Technologies in PCR Testing and the Last Mile Problem

Using robot technologies, Kawasaki has responded to the unparalleled severity of the pandemic. While the spread of the novel coronavirus steeply increased the demand for PCR testing, Kawasaki promptly initiated development of an automated robotic PCR testing system and completed it at the astonishing speed of six months, starting the service of automatic PCR testing system that can handle a massive number of samples in a short time by robots. Since the entire system is designed to fit in a 40-foot container, it can be dispatched to airports, event venues, and other similar locations, and the PCR testing service is actually offered for international passengers at Kansai International Airport.*1

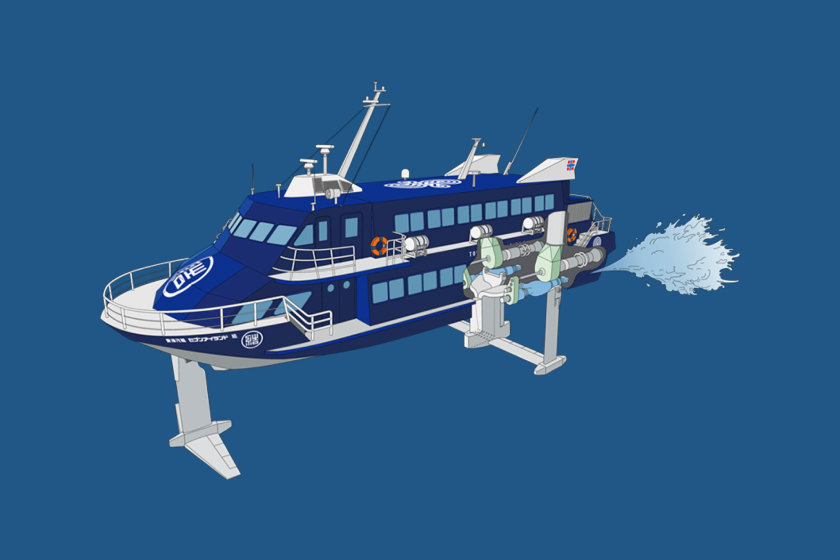

To make a Safe and Secure Remotely Connected Society after the COVID-19 pandemic, Kawasaki will provide new solutions using robot technologies and its extensive expertise to deal with mobility on land, sea, and air. For example, the Company succeeded in a test flight of the unmanned VTOL (vertical takeoff and landing) helicopter K-Racer and is looking for possible applications as transportation that can fill the gap between crewed helicopters and small drones to deliver freight to remote locations. In addition, Kawasaki is aware of the issues of last mile*2 distribution (the last section of logistics to deliver goods to end users). With the use of techniques of utility vehicles and motorcycles, automatic delivery robots capable of traveling even on rough roads and streets with steps are being developed.

*1 Press release of Kawasaki, PCR Test Center Launches at Kansai International Airport

*2 Physical distribution service from the final business base to end users. It does not simply refer to a mile of distance in the ultimate leg but the last part of logistics to deliver products to users.

The word robot fascinates us because it provokes a sense of the future. However, robots already work around us.

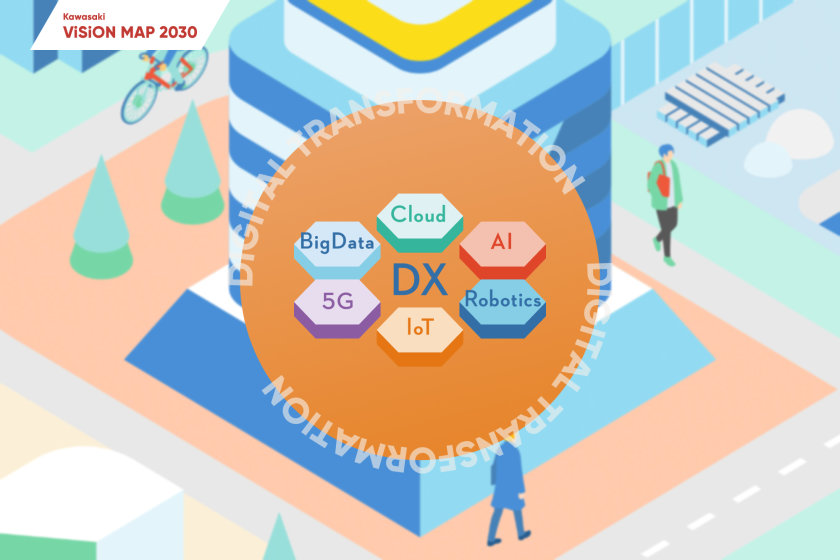

Group Vision 2030, the business policy of Kawasaki announced in November 2020, describes a new remotely connected society integrated with robotics and mobility. Remote factories where robots operate from a safe, distant place, such as your home; care services to follow patients by means of autonomous robots; and unmanned logistics with drones and self-propelled robots—by 2030, robots will become widespread into every corner of society, and the world will look like a future we have dreamed of. In the not-too-distant future, you will see a safe, secure society that allows you to connect to anyone no matter where you are.

Where on earth are robots from?

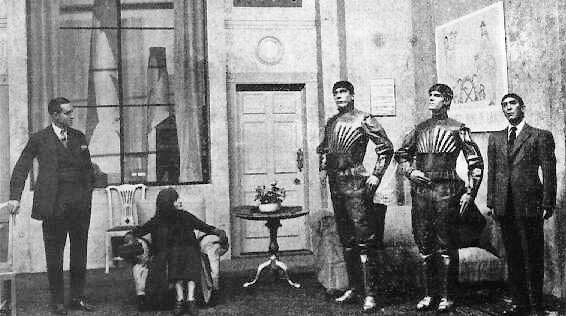

In the first place, the term robot was created from the Czech expression "robota” meaning hard work and labor. The most widely held theory is that the term was first used in R.U.R. (Rossum's Universal Robots), a play written by Czechoslovakian writer Karel Čapek in 1920. The play is animated by the speaking, running, and moving of artificial human beings provide the manual labor, i.e., robots. It is not only that Čapek’s description of robots in an imaginary world attracts many people as unique, key players but also that sci-fi works from all ages and countries, such as novels by Isaac Asimov and Philip K. Dick; films Star Wars, The Terminator, and RoboCop; and anime of Astro Boy, Ghost in the Shell, and Neon Genesis Evangelion, include diverse humanoids, androids, and cyborgs that perform astonishing jobs in multiple fields.

It is true that the concept of mechanical devices capable of complicated motions like humankind existed long before the word robot appeared. For example, in The Iliad, an epic poem attributed to Homer in the 8th century BCE, Hephaestus, the god of fire and metalworking, creates golden handmaidens. In a chapter of Liezi, which was written in the 4th century BCE, an engineer called Yan Shi makes an elaborate human-like robot for the king of the Chinese Zhou Dynasty.

The representation of robots became more concrete in the 12th century. The Muslim inventor Ismail al-Jazari wrote The Book of Knowledge of Ingenious Mechanical Devices, leaving mechanisms and methods of a hand washing automaton and a musical robot band in detailed drawings. Around the year 1495, the genius Leonardo da Vinci drew the design of a mechanical knight, which was able to move its head and arms.

In the 18th century, all artisans in Europe and Japan produced complicated automata (machines without human control). The French inventor Jacques de Vaucanson created an automated duck, which could drink, eat, and even defecate. Meanwhile, Tokyoite Hisashige Tanaka, known as "Japan's Edison” or "Karakuri Giemon,” made greatest karakuri dolls, including the Yumi-Hiki Doji (arrow-shooting boy) and the Moji-kaki doll (letter-writing doll).

Subsequently in the late 1920s, three humanoids appeared in the United States, Great Britain, and Japan. Westinghouse Electric Corporation, an American electronics manufacturer, built Televox to control home appliances remotely. The British duo Captain William H. Richards and aircraft engineer Alan Reffell invented a robot named Eric, which was able to sit and stand. In Japan, biologist Makoto Nishimura created Gakutensoku, and the robot could change its facial expression and write Japanese characters.

Humanoid robots made the leap from a 2D world to a 3D world and finally started to grow in reality. Many robots then emerged, including Waseda University's Wabot, Honda's Asimo, the HRP series of the National Institute of Advanced Industrial Science and Technology, Softbank’s Pepper, and Sharp’s RoBoHoN for interaction with people.

Nowadays, robot technologies are expanding the areas of application to support our lives in the real world, including wearable exoskeleton suits for motion assistance, non-pharmacological therapeutic robots for inner peace, and underwater drones to inspect subsea oil pipelines. Robots, which have been a dream since ancient times, have infinite possibilities.

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment