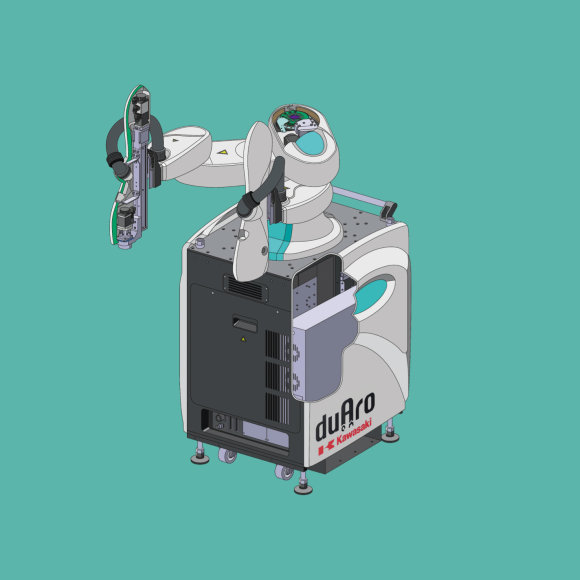

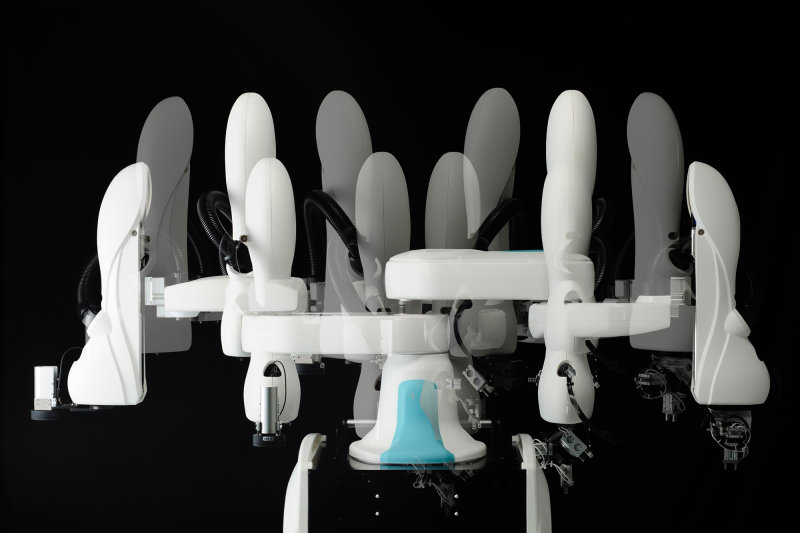

duAro A Dual-arm SCARA (Selective Compliance Assembly Robot Arm) Robot that Achieves Human-Robot Coexistence

The duAro, a dual-arm SCARA robot that operates alongside humans, was launched in 2015, based on Kawasaki’s experience as the first company to commercially manufacture robots in Japan. The debut of this robot marked the company’s commitment to pioneering a new era of coexistence and collaboration between robots and humans.

Pioneering Robot Applications in Areas Previously Deemed Unfeasible

As Japan faces an ever-shrinking workforce, manufacturing sites in dire need of replacing that vanishing manpower with industrial robots are increasing. However, introduction of robots at companies such as those in the electrical and electronics industries has been hampered by unjustifiably low cost-effectiveness, given the short life-cycle of their products and the lengthy preparation period required for their introduction.

Another negative factor contributing to reservations felt by small and midsized companies, which make up the majority of Japan’s industry – the very groups most in need of robot applications – has been their lack of expertise in robotics.

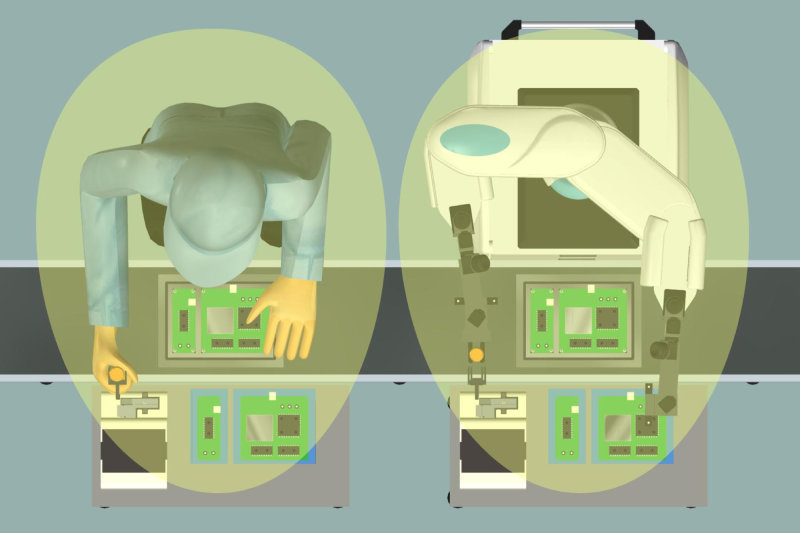

The duAro was developed to resolve these challenges. Standing up to 170 cm tall, and weighing 200 kg, the duAro is installable in the working space of a single human worker. It can be taught easily by the simple means of step-by-step direct teaching, or by using a tablet. Its two arms can perform separate tasks, and with its collision detection features, the safety of collaborative operations with humans is assured. The duAro also comes with a price tag that is reasonable enough to make it a viable option for implementation, which has been contributing to its popularity more than any other factor.

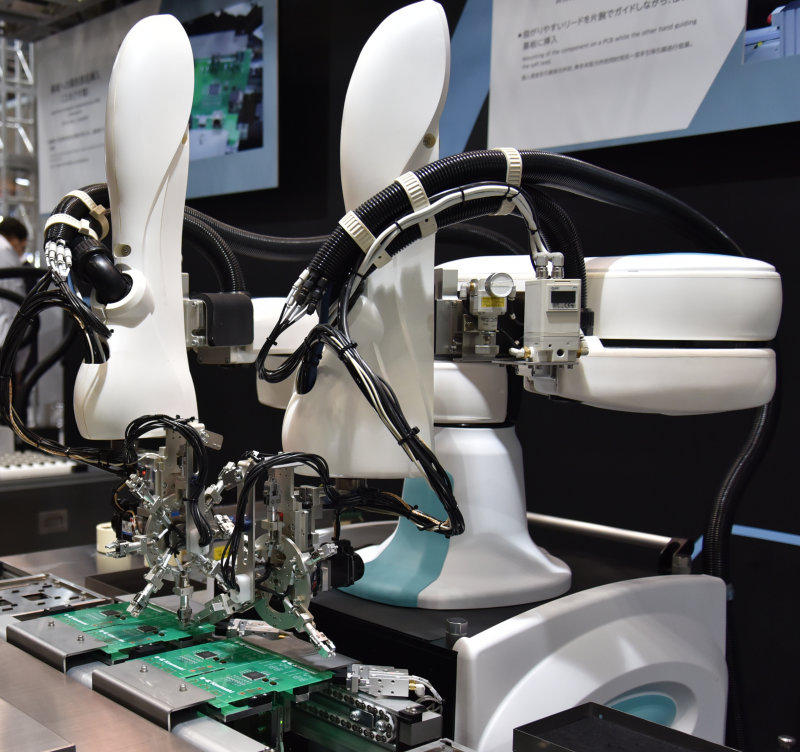

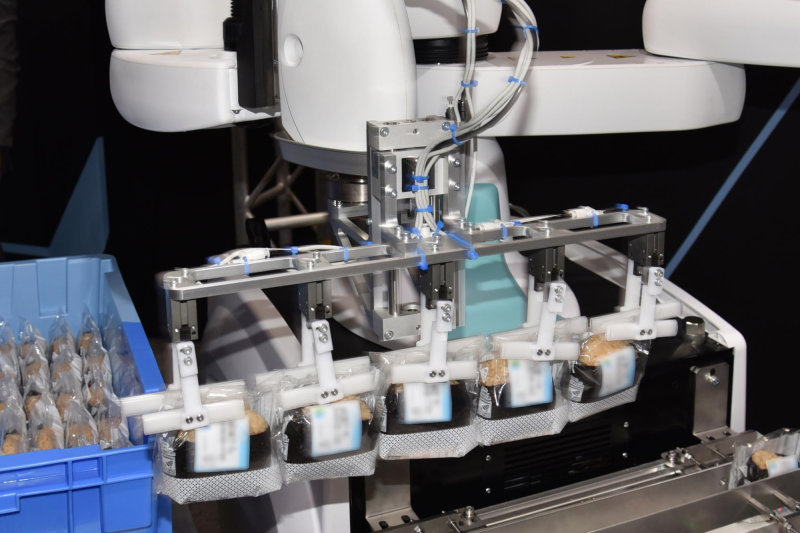

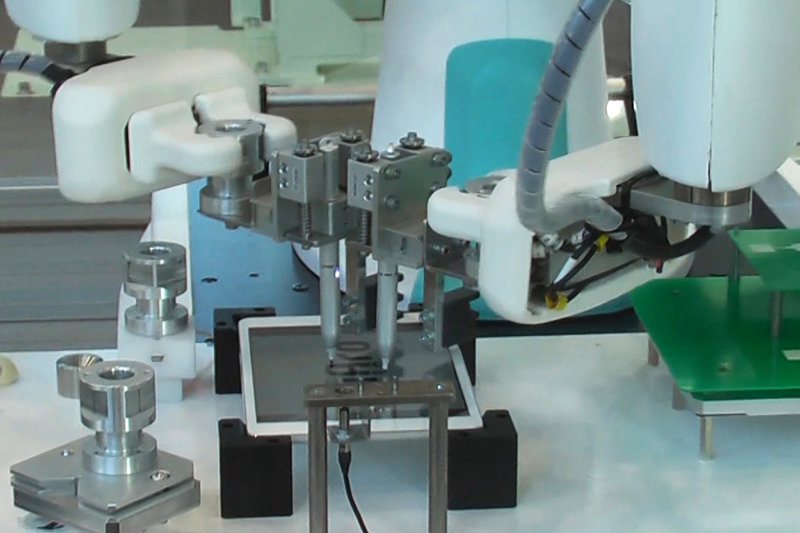

Since its launch, these benefits have been expanding the horizon of duAro’s applications. From the fastening of screws for printed circuit boards (PCBs), to the picking and placing of rice balls into food trays, the duAro is an innovation that is sure to become a key contributor to the future growth of the manufacturing and service industries in Japan.

Diverse Tasks Can be Robotized as Needed

Various tools are attachable to duAro’s arms, enabling the robot to perform a wide range of tasks. Past applications include the mounting of parts on PCBs, the placing of rice balls in food trays, and inspections of functions and response capabilities of touch screens, to name a few, and many more are likely to be added.

An impressive lineup of options is available for customization.

The duAro can remedy increasing labor shortages.

Dual-Arm Feature that Mimics the Marvelous Dexterity of Human Hands and Arms

The duAro is capable of accurately reproducing human arm and body movements. Each arm, 76 cm long when fully extended (152 cm when both arms are extended), was designed based on the average working space of a human worker. By using simple “hands” (effectors) attached to the end of each arm, the duAro is able to grasp a large workpiece and move it (Fig. 1), and thanks to its coaxial configuration, the robot can also reach equipment at its back (Fig. 2). The arms can also perform separate tasks (Fig. 3). For example, when working on a PCB, the left arm can hold the PCB while the right arm tightens a screw. This results in shortened takt time (cycle time) and simplified production systems, because tools to hold the PCB are no longer necessary.

Flexible Direct Teaching Features

The controller for the robot arms is housed in a wheeled, box-shaped platform which is easily moved to a desired location, allowing the robot to perform tasks in any part of the production line.

There are two simple ways to teach the duAro: direct teaching or via the Android-based tablet. In the former, the operator performs a task holding the robot arms to make it reproducible by duAro. In the tablet-based method, the operator configures the required movements by inputting numerical values. Both are very simple means, requiring no specialized knowledge.

With its weight accounting for 75% (145 kg) of the entire robot, the platform provides needed stability for the duAro to move its arms.

Low-Power Motors Adopted for Operations Free of Safety-Fencing

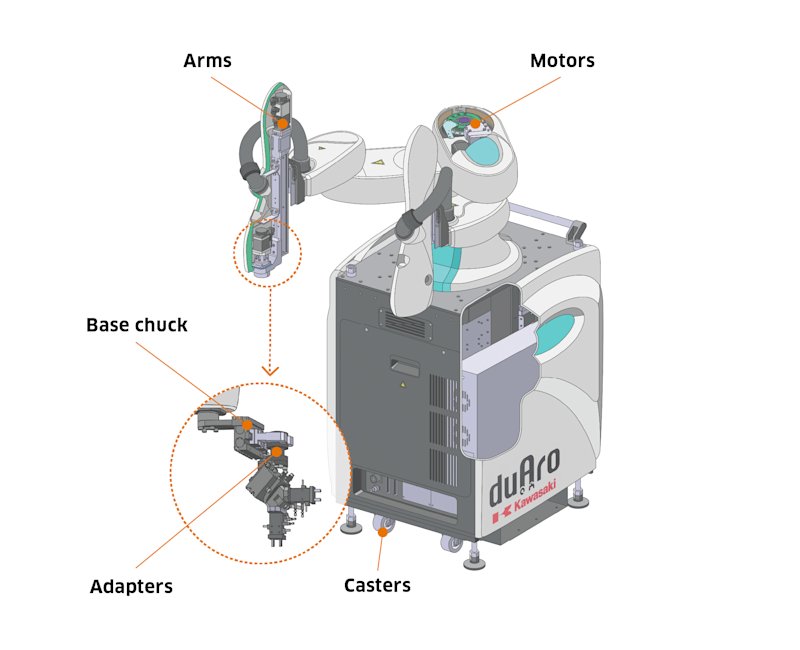

The arms are driven by motors mounted on their “shoulders,” “elbows,” and “hands,” and their movements are controlled by changing the number of the motors’ revolutions.

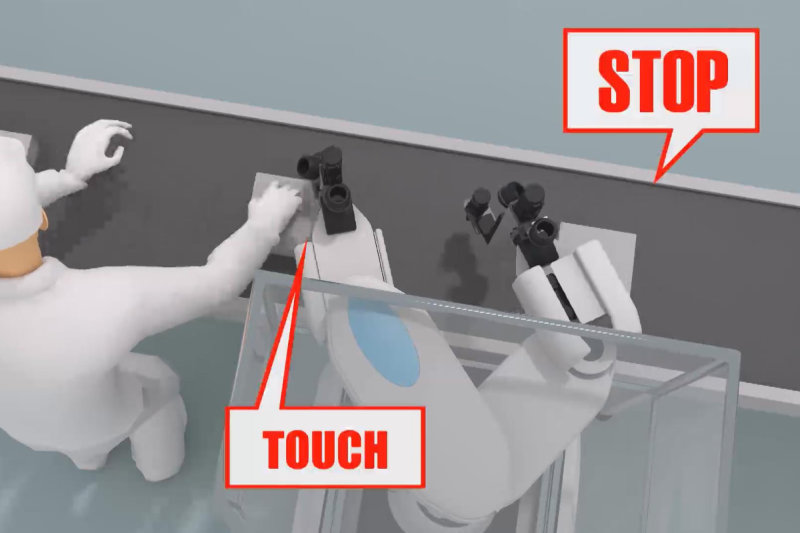

The arms, padded with soft material, can be configured to move at different speeds in different zones; setting the low-speed areas at either side of the robot, where human workers might approach, allows the robot to move slowly in those two areas while it operates at high speed in the center zone. The robot is also equipped with sophisticated safety measures, including a collision detection feature which instantly stops any arm movement when people come in contact with the robot and the impact is detected.

Existing Tools Are Also Usable

Tools that customers have been using are attachable to the duAro, using base chucks and adapters. An impressive lineup of accessories is additional proof that Kawasaki is committed to accommodating the needs of customers hoping to robotize human tasks expeditiously.

Automated Smoothing of Horizontal and Vertical Movements

The arms of the duAro are movable in horizontal and also z-axis (up and down) directions, and each arm is capable of lifting a workpiece of up to 2 kg. The movement in the z-axis direction can be taught through direct teaching, and the smooth up/down movement of the arms is achieved by features such as measurement of the weight of the jigs attached to the end effectors.

Casters

The platform is equipped with casters and can be moved simply by pulling the handle, which allows for easy change of location by a single worker.

FA System Section 1

FA System Department

FA and Clean Group, Robot Division

Precision Machinery and Robot Company

Kawasaki Heavy Industries, Ltd.