Ever since it developed Japan’s first industrial robot, Kawasaki has blazed a trail through many uncharted terrains laying the foundations of the robotics industry.

Industrial robots have become indispensable in modern manufacturing. Japanese industrial robots command a majority share of the world market, and as a major robotics center Japan supports manufacturing around the world.

In alliance with Unimation, a US company founded by Dr. Joseph Engelberger, who is called the father of industrial robots, Kawasaki succeeded in producing the first Japan-made industrial robot in 1969. Robots were increasingly adopted by major automakers in the 1970s, and this led Japan down the road toward becoming a major player in industrial robots.

Various uses for robots have been tested at the facilities of Kawasaki, and the knowledge gained has allowed adaptation to a wide range of industrial fields. For example, the automated operations system for machine tools developed at the Akashi Works in 1971 was the first test utilization of industrial robots for the automation of mechanical processing. At one point there were over 200 robot manufacturers, but competition caused a convergence to the remaining manufacturers, which all share a common trait: it is a drive to seek new areas for applying robotics technology, much like Kawasaki did during the period of rapid growth in robotics. In that sense, development of industrial robots at Kawasaki helped form the DNA of the robotics industry for all of Japan.

First Japanese Industrial Robot Unimate 2000

Kawasaki signed a technical partnership agreement with the US company Unimation in 1968, and launched the first Japanese commercial production of industrial robots in 1969.

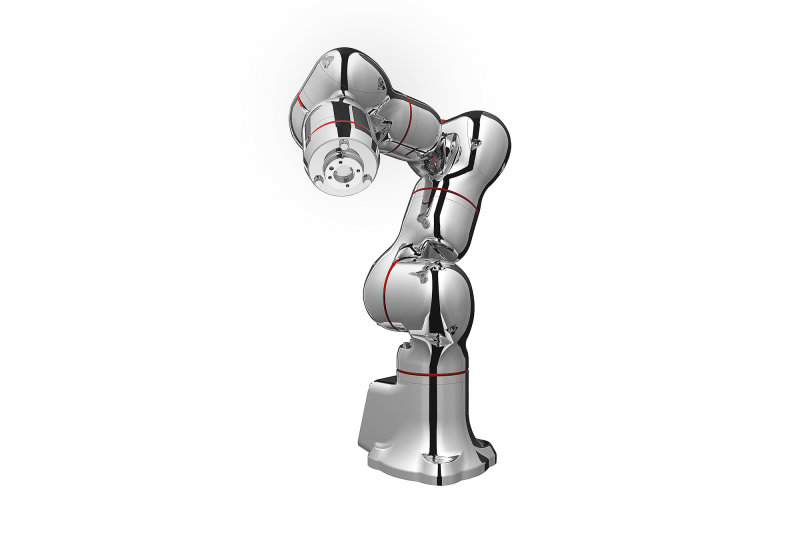

Clean Robot NT Series

Designed for semi-conductor manufacturing in cleanrooms, where not even a speck of dust can be allowed, this horizontal articulated robot is used in wafer transport. A unique drive mechanism provides high accuracy and stiffness, as well as smooth movement.

Vertical articulated welding robot. Greatly shortened cycle time by lightening the arm, using a high-output high-speed compact motor, and implementing the latest anti-vibration control technology. In addition, it internally houses cables and hoses within the arm, thereby eliminating interference with neighboring robots and peripheral equipment.

High-Speed Picking Robot Y Series

Two compact models with a maximum payload capacity of 2 kg or 3 kg support safe, high-speed, high-accuracy transport. These models can be used in a wide variety of applications, from production lines for food products, pharmaceuticals, and cosmetics, to electronic equipment.

Spot Welding Robot B Series

Medical and Pharmaceutical Robot MS005N

Kawasaki is now a pioneer in the field of medical treatment and health care, where demand is increasing for automated operations performed by robots. This model works to prevent workplace errors and intrusion of microbes that can occur with the intervention of human personnel, and it prevents infection from the handling of high potency active pharmaceuticals such as anti-cancer drugs. Its stainless steel construction gives the MS005N high resistance to medicinal liquids, provides easy cleaning, and remains highly sanitary.

Industrial robots combine technologies such as mechanics, electronics, computers, servo- motors and sensors, and they are supported by implementation, production and workplace technologies, thereby wielding much power in the industrial arena. Backed by this combination of forces, Kawasaki’s robotics business is guided by a philosophy of human-oriented manufacturing, where harsh and demanding tasks are left to robots while the human workforce concentrates on other operations.