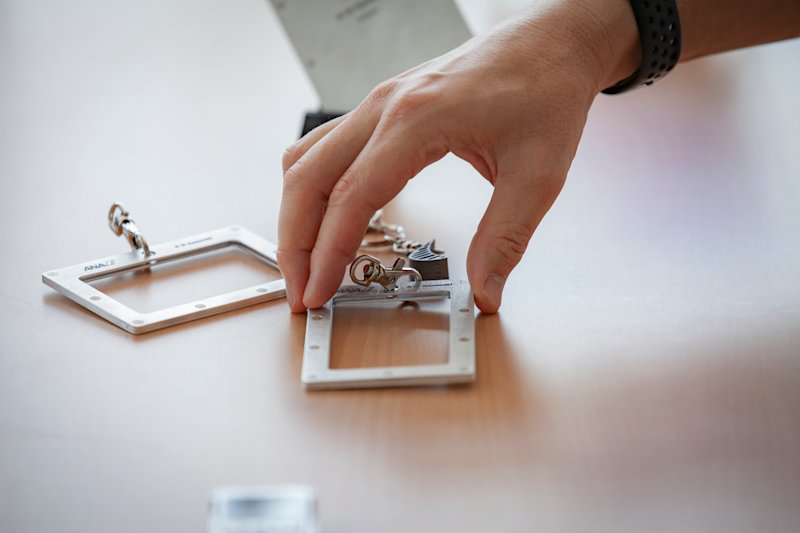

After a year and a half of preparation by ANA and Kawasaki for their upcycle project, several key products were created – keychains made from the engine blade of a Boeing 737, and card cases, tablet stands, and business card holders made from leftover materials generated when manufacturing the fuselages of the Boeing 767 and 777. Although these items are familiar everyday items, the more you touch them, the more you feel their energy. These tiny products incorporate technology that allows huge aircraft to fly tens of thousands of nautical miles through the sky.

Engineering & Maintenance Center

All Nippon Airways Co., LTD.

All Nippon Airways Co., LTD.

Fabrication Manufacturing Engineering Department

Manufacturing Group

Aerospace Manufacturing Division

Aerospace Systems Company,

Kawasaki Heavy Industries, Ltd.

Commercial Aircraft Business Management & Operation Department

Commercial Aircraft Program Management Group

Commercial Aircraft Business Division

Aerospace Systems Company,

Kawasaki Heavy Industries, Ltd.

Commercial Aircraft Business Management & Operation Department

Commercial Aircraft Program Management Group

Commercial Aircraft Business Division Aerospace Systems Company,

Kawasaki Heavy Industries, Ltd.

What can we do to revitalize the aviation industry?

Mr. Ikari of ANA, the proposer of this project, explains the products while pointing to the rivets of the card case:

Aircrafts have as few concave and convex surfaces as possible to reduce air resistance and increase fuel economy. When we feel the surface of this card case, we find that the rivet heads are completely embedded in the aluminum alloy plate surfaces, and no surfaces are uneven.

If you imagine a nail being driven into a plywood sheet, you will find that it is extremely difficult to drive nails to the same level as the base material without the heads protruding. Sometimes they may protrude slightly, or they may be driven too deep. High-precision processing technology is required to realize a completely flat surface. In the case of metallic materials, the difficulty increases. High-quality workmanship, where the rivet heads are completely flat with the base material, can be achieved because we have the technology and skill to manufacture aircraft parts. Mr. Fujihara of Kawasaki says:

An aircraft consists of millions of parts, which Kawasaki cannot manufacture alone. The manufacturing of aircraft parts is possible only with the cooperation of many partner companies. It is very meaningful to us that we can gain the cooperation of our partners to create products for this upcycle project

For example, high-precision three-dimensional digitalization technology and the manufacturing technology cultivated in the fabrication of jigs and tools, as well as the machining of difficult-to-cut materials by Nabeya Manufacturing, are all used in the processing of the engine blades for this keychain. Likewise, the creation of the card case and business card holder requires the expertise of Tenryu Aero Component, which handles all processing from the machining of parts made of aluminum alloy and composite materials, to surface treatment and painting, as well as fuselage assembly.

Clockwise from top left: B767 tablet stand, B737 engine blade keychain, B767/777 business card holder, and B767 card case

Mr. Kojima, who led the project together with Mr. Ikari, continues

I heard that rivets are manually driven into the Boeing 767 aircraft. Imagining that the same person who drove rivets into the Boeing 767 aircraft may have driven the rivets into this product in my hand – it’s deeply moving.

The unexpected byproduct of upcycling

One unique aspect of this project is that Kawasaki and its partner companies were involved from the brainstorming phase of these products

In our ordinary work, we ask manufacturing partners to fabricate as specified in the drawings. But this time, we asked them to try and create something from the given material. Our partner companies became keenly interested in the project and agreed to this totally different approach. I also heard that it led to an increase in motivation within their day-to-day work, as well.

The aforementioned riveted section incorporates several ideas from Tenryu Aero Component to realize completely flat surfaces. Through the exchange of ideas, project members started to see surplus materials in a different light.

Everyone came up with various ideas, and I also began to look at leftover and surplus materials in a different way. I started to explore the possibility of future products – any material has the potential to be used for something useful instead of being discarded. I think this project has created new value, not just for the products, but for us working in the aviation industry.

This project started with the aim of creating one solution to environmental concerns, introducing a product for aviation enthusiasts, and revitalizing the airline industry and its contributing regions. However, through this process, we ourselves were greatly inspired.

Because most of our clients are corporations, we have few opportunities to create products for general consumers. Unlike our day-to-day work of creating products accurately from drawings, we thought of ways to bring joy to everyday people, which allowed us to approach our products from a different perspective. This opportunity was incredibly valuable for us.

Through this project, I hope many people become interested in the unique products that Kawasaki and partner companies offer. I believe we can accomplish even more in partnership with ANA.

For the next phase of this project, Mr. Ikari has already started to outline a concrete vision.

We do not simply want to be a system of transportation. We want to increase the number of people interacting with each other by creating 'mechanisms' that stimulate demand for travel and make people want to travel. We hope that more people will visit Kakamigahara City in Gifu Prefecture when they find out these products are manufactured there. For the next phase of our project, we also plan to develop this product as a hometown tax return gift as a mechanism for people to experience Kakamigahara without having to visit the place in person. We would like to continue to create various 'mechanisms' for regional development that only an airline company like us can provide.

The upcycle project created by ANA and Kawasaki Heavy Industries is an endeavor with the potential of bringing greater value both to those who create products, as well as those who consume them. The challenge has just begun. We hope this newfound potential will spread its wings and continue to fly boldly forward.

《Notice of Product Restock》

We are pleased to announce the restock of our upcycled product that sold out almost immediately upon its initial release. The restock will be available for purchase on "ANA mall" starting from September 29, 2023 (Friday). For more details, please visit the "ANA mall " website.