Under the slogan “Your Idea Can Change Society and Our Company,” the Business Idea Challenge (BIC) was established at the Kawasaki Group in order to solicit ideas with great business potential. We are using this program to develop personnel who will boldly transform the status quo and infuse our corporate culture with a spirit of challenge. Currently, the business models of three ideas that have been submitted are undergoing feasibility reviews, after which they will receive further reviews and funding consideration with the goal of commercialization.

This program was launched in April 2020 to accelerate open innovation initiatives at the Kawasaki Group and to broadly solicit unpursued business ideas that are unconstrained by our existing products and businesses, but still leverage the strengths of the submitters and the Group. These ideas will be adopted to develop a variety of new products and businesses that accommodate rapid changes in market environments and customer needs. To that end, as needed, we plan to collaborate with both start-up ventures and major companies.

Using agile development methodology, in which product/service planning and reviews are repeated in short cycles, we plan to achieve efficient and speedy creation of new added value. Another aspect of BIC is to strengthen entrepreneurship among submitters by offering the financial accounting and business strategy education needed for creating new business models, so that they become resources for Kawasaki’s sustainable growth.

In the first year since the call for ideas began, 178 ideas have been submitted. Currently, the business models of three of the submitted ideas are undergoing a review phase which will last about six months. If they are approved for further consideration, the Company will grant one year’s worth of activity funds to the submitters to advance the ideas toward commercialization, the progress of which will be subject to ongoing review.

Comfortable Mobility for Daily Use with Low Center of Gravity that Keeps Riders from Falling: The Electric Three-wheeled “noslisu”

This three-wheel vehicle was developed to provide a safe, comfortable, and easy-to-use means of mobility to senior citizens and those living in areas with inadequate public transportation systems, to improve their quality of life. There are two types to choose from: an electric vehicle type that requires no pedaling or a power-assisted bicycle type. It offers a smooth and safe ride with a low risk of falling off, and because of its low center of gravity, it is slip-safe even when transporting heavy goods on a rainy day. It is planned to be put on the market in the latter half of FY2022.

(Submitters: Advanced Development Department, Research & Development Division, Motorcycle & Engine Company, and others)

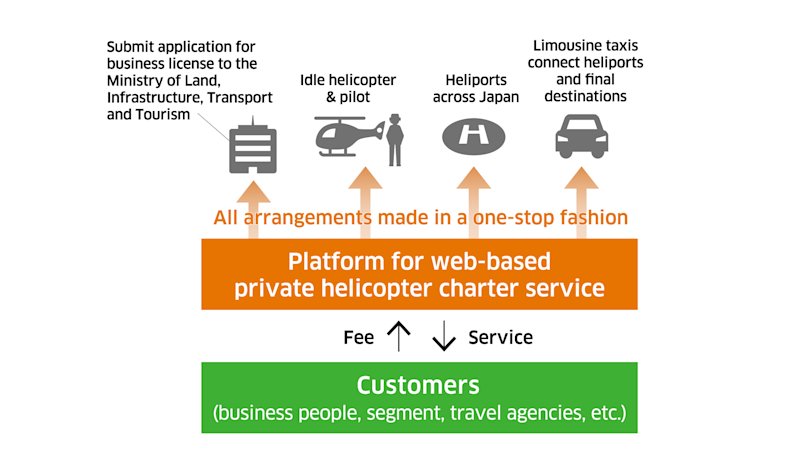

A Convenient Flight Service Utilizing Helicopters That Are Often Left Idle: “Web-based Helicopter Charter Service”

Statistics show that, on average, a helicopter in Japan flies less than one hour per day. This web-based service will connect these underutilized helicopters with consumers who wish to charter helicopters. Backed by its highly-trusted helicopter production and maintenance capabilities, Kawasaki will play an integral role in connecting these two parties.

By making all flight-related arrangements in a one-stop fashion, Kawasaki can improve both the business environment for helicopter operators and customer convenience.

(Submitters: Helicopter Department of the Marketing and Sales Division, Aerospace Systems Company, Helicopter Project Group of the Aerospace Business Division, Aerospace Systems Company, and others )

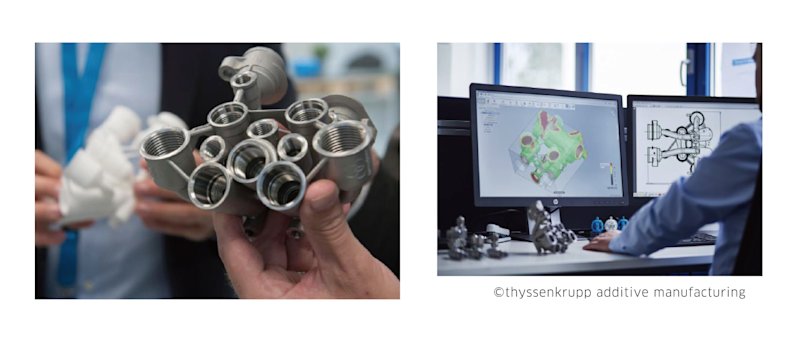

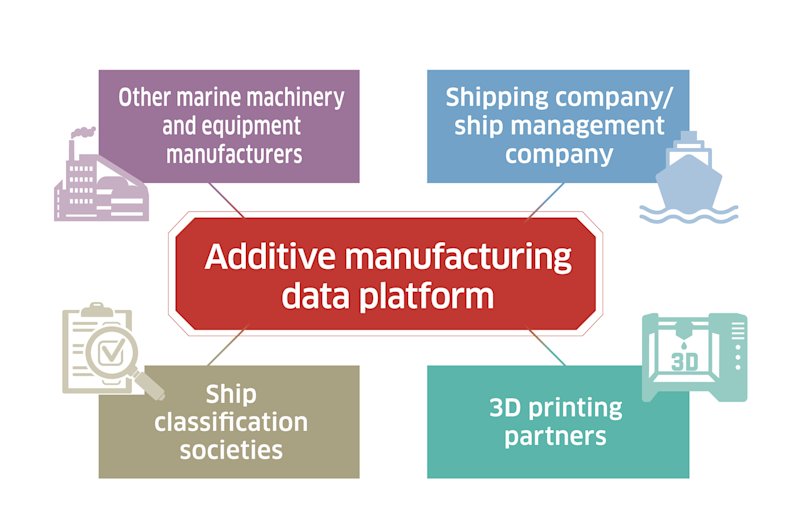

A Platform that Promotes a Transition from Physical Transport of Goods to Data Transfer, Made Possible by a 3D Metal Printer: “Marine Repair”

About 116,000 merchant vessels are in operation around the world. If a ship breaks down during a voyage, spare parts have to be shipped to the nearest port, which is a time-consuming and costly process.

Marine Repair is a service that will offer a data platform for several partnering companies with 3D printing systems for marine applications which are located near seaports, enabling them to manufacture genuine 3D-printed parts on the spot. A consortium, of which Kawasaki is a member, has been selected by the Maritime and Port Authority of Singapore to participate in a program advancing the use of 3D printers, and a demonstration to verify the efficacy of 3D-printed parts is scheduled to be conducted soon.

(Submitters: Marine Machinery Sales Department, Marketing & Sales Division, Energy Solution & Marine Engineering Company, and others)