H&V (Horizontal and Vertical) Shield Machine Drives Forward Challenging Underground Construction Projects

Shield machines excavate the soil for underground tunnels using rotating cutters located at the front of steel units. This invention has been used for roughly 200 years, and now an excavation method using two shield machines in parallel, called the H&V shield tunneling method, is in practical use. Begun in 2013, a Tokyo Metropolitan Government Sewage Bureau project to construct pipelines to drain rainwater overflow from the Tachiaigawa River (in Shinagawa, Tokyo) to the Keihin Canal saw the world’s first implementation of the H&V shield tunneling spiral excavation method. The key player was Kawasaki, and its technological prowess was proved by the delivery record of about 1,400 shield machines that contributed to making possible another world’s first.

Kawasaki Achieves World’s First Spiral Excavation by H&V Shield Tunneling Method

Shield machines excavate underground tunnels using rotating cutters located at the front of these steel units. As a result of impressive technical advancements over the last 200 years, very complex projects can now be carried out using two shield machines designed to work in tandem ― an excavation method called the “H&V Shield Tunneling Method.”

Begun in 2013, a Tokyo Metropolitan Government Sewage Bureau project to construct pipelines for draining rainwater overflow from the Tachiaigawa River (in Shinagawa, Tokyo) to the Keihin Canal saw the world’s first implementation of this H&V Shield Tunneling “spiral excavation” method. In this type of excavation, two shield machines are initially configured either side-by-side (horizontal configuration) or one on top of the other (vertical configuration). As they move forward, however, they spiral to alternate from a horizontal to a vertical configuration or vice versa. In the rainwater overflow drainage project, the machines excavated with their positions changing from the horizontal to the vertical settings.

Each machine is 5.85 m in diameter and weighs about 400 t. Amazingly enough, these gigantic machines were able to follow the meandering of the river as they excavated, maintaining an extremely narrow, 9-cm space between them. Key to this success was the “flexible joint mechanism” of the pins. It enables each machine to move helically around an axis to achieve spiral excavation, while the two machines stay connected. The previous connection was a fixed one, allowing the rear bodies to move only in the same direction.

To date, Kawasaki has delivered 1,400 units of shield machines for both domestic and international tunneling projects. Some of them were used in constructing the Channel Tunnel beneath the Strait of Dover between the UK and France, which the American Society of Civil Engineers recognizes as one of the top 10 civil engineering achievements of the 20th century in the railway category. Kawasaki’s technological prowess contributed to making possible another “world’s first”.

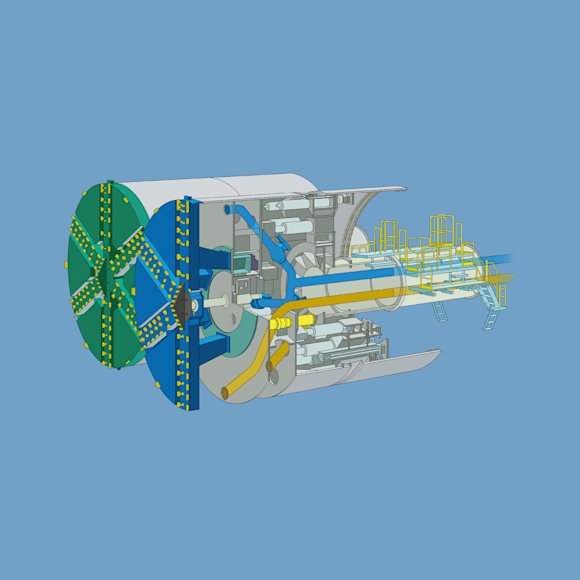

Flexible Joint Mechanism of the Connecting Pins that Made Spiraling Possible

In this rainwater overflow drainage project, the machine to the right advances upward and to the left, gradually achieving a vertical configuration. Because the machine had to be articulated at 3.9 degrees and perform three-dimensional movements, development of a flexible joint mechanism was essential. The two shield machines, placed in horizontal configuration in the departure shaft, perform spiral excavation for about 137 m, then change their position to a vertical configuration and excavate a further 600 m.

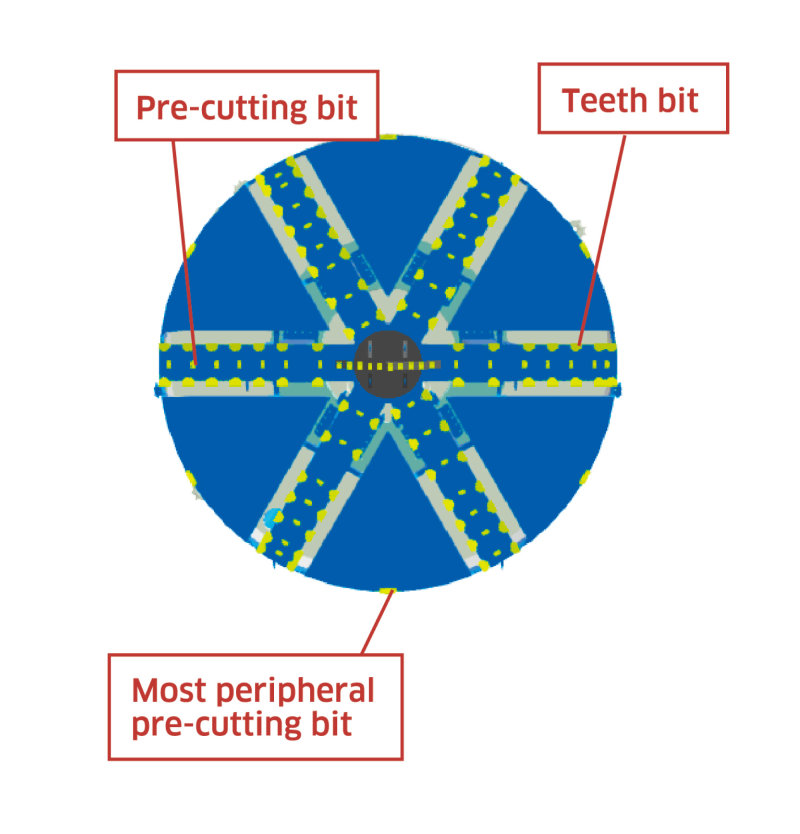

Cutter head

The shapes of the face plate and the excavation cutter bits are designed to accommodate the geological features of the site and the hardness of the soil. The fact that the chips mounted on the cutter are made of carbide is indicative of the challenges involved in excavating earth with varied geological features, soil properties, and pressures.

Shield jack

In the shield tunneling method, the tunnel wall structures (segments) are built to the rear of the shield machine as it advances. Shield jacks apply force to the assembled segments to push the machine forward.

Slewing bearing

This bearing transmits power from the cutter-driving electric motor to rotate the cutter head.

Articulation jack

This jack supports excavation of curved tunnels by allowing the anterior body of the machine to flex.

Working deck

This area within the machine permits workers to perform segment assembly and other tasks. Even when the machine is spiraling, the angle of the working space floor changes (up to 90 degrees) so that the deck remains level.

Cutter-driving electric motor

The shield machine is equipped with six reduction gear motors to drive the cutter, which rotates at 0.82 rpm.

Slurry feed and discharge pipes

A partition is installed toward the anterior of the front body (in the case of a sealed machine). In the slurry shield tunneling method, slurry prepared at the ground plant is fed into the chamber (via the slurry feed line) to counteract the ground water pressure, thereby stabilizing the surrounding soil. Excavated soil is discharged to the ground plant after being sucked up by a pump installed on the carrier behind the machine (via the slurry discharge line).

Project to Accommodate Challenging Urban Restrictions

The site for constructing two 5-m diameter pipelines under the Tachiaigawa River for draining excess rainwater is approximately 778-m long. The pipelines will take up rainwater overflow to prevent flooding in the vicinity and contamination from sewage coming from the “combined sewage system.” The excavation under the river first required the shield machines to go under the revetment pilings near the departure shaft. It also necessitated that the machines maintain an excavation path of less than 8 m to stay within the river’s width. It was a challenging project with many restrictions to deal with. However, thanks to Kawasaki’s shield machines which are capable of spiraling, coupled with robust project management by Shimizu Corporation, the excavation, which began in March 2018, was completed in July 2019.

Section 3

Quality Assurance Department of Quality Assurance Division

Energy System & Plant Engineering Company

Kawasaki Heavy Industries, Ltd.

Tunneling Equipment Department

Energy System & Plant Engineering Company

Kawasaki Heavy Industries, Ltd.