The 3000 Series Debuts on Kobe New Transit's Rokko Liner

Subdued blue-green train cars travel quietly through the city of Kobe. The new model cars are part of the Rokko Island Line (commonly known as the “Rokko Liner”), which has provided the connection between downtown Kobe and Rokko Island for more than 30 years since it started operation in 1990. Detailed consideration and wisdom of the engineers are behind the design of the cars, which incorporate many of the ideas reflecting the fascinating city of Kobe and comprise a part of the lives of the citizens in a natural manner.

Designed to Foster a Feeling That the Rokko Liner is Part of Everyday Life

On August 31, 2018, Kobe New Transit inaugurated the use of the 3000 Series train cars on the Rokko Island Line (commonly known as “Rokko Liner”), connecting Sumiyoshi in Kobe City and Marine Park Station on Rokko Island, a man-made island with a population of about 20,000. This was the first time since this automated guideway transit (AGT) system opened in 1990 that the cars had had a model changeover. By the end of fiscal 2023, a total of 44 cars (11 sets of four-car trains) will be replaced by the 3000 Series model.

The development of the new train was entrusted to Kawasaki, which had developed the preceding 1000 Series. As a starting point in formulating the design concept, Kawasaki’s project team conducted a fact-finding study on the perceived benefits of living on Rokko Island and using the Rokko Liner. This was done by organizing a web-based survey of 121 users, and holding “Co-creation Conferences” with an additional four users representing different age groups.

Based on the survey results, the team came to the conclusion that the new trains needed to foster a feeling in the users that the Rokko Liner is as much a part of everyday life as watching the beautiful dawns and sunsets from their seaside homes, or the sense of relief they experience when crossing the bridge on the way home. As a result, the train was designed to resemble a smart-looking ship, as passengers “sail” to and from Rokko Island across the sea aboard the Rokko Liner, and as a theme color, a subdued blue-green inspired by Kobe’s iconic oldest gaslamp was selected.

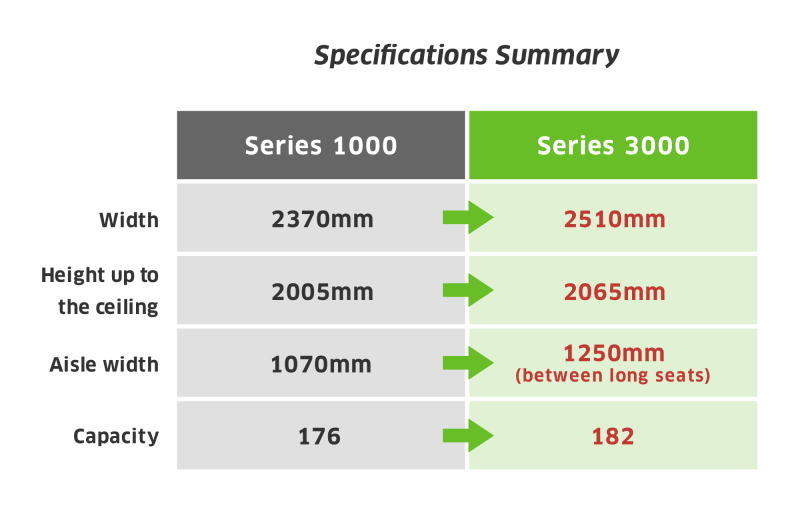

Also, to make the ride more comfortable and pleasant, many ideas were incorporated, such as increasing the width of the train by 14 cm on the aisle side to make it roomier, and introducing seats with openings in the backrests to allow more light to come in from the windows.

New Levels of Safety and Comfort Attained

The new cars have large windows that allow passengers to view beautiful scenery and to enjoy a brighter ambiance. Windows facing private residences along the railway are instantly switchable to privacy (frosted) glass. Moreover, in order to ensure both safety and comfort, security cameras are installed on each end of the cars, and plasma-cluster ion air purifiers help to create a hygienic environment.

A Compact Space Packed with State-of-the-art Technology

Because the 3000 Series has higher ceilings, increased width, and a lowered floor to make the train roomier, space allocated to train equipment was greatly reduced. Also, the same lineup of equipment as that for the typical 18- to 20-meter long car needed to be squeezed into this eight-meter long car. Therefore, the shapes of the equipment and their layout were re-designed, resulting in more compact and higher-performing equipment that is as effective as that of previous models.

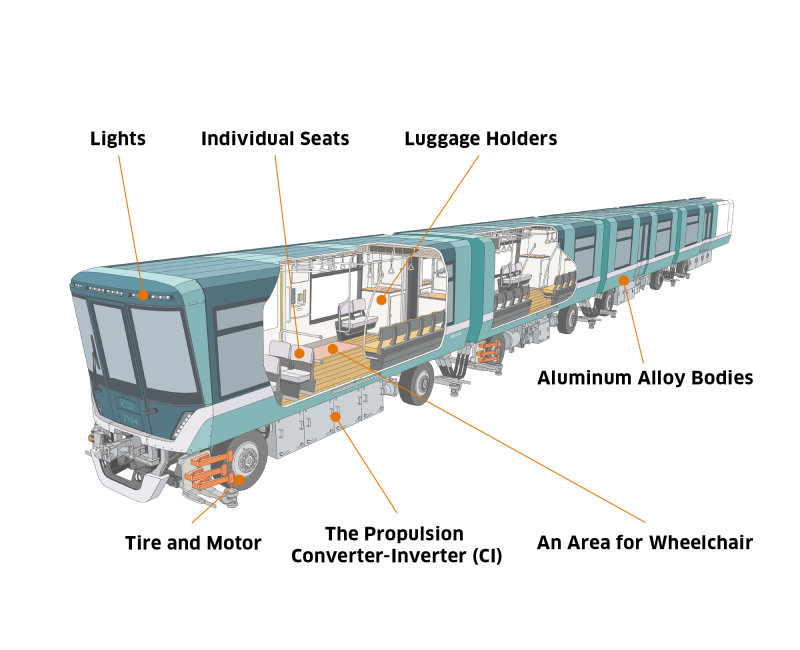

The Propulsion Converter-Inverter (CI)

The propulsion inverter accelerates or decelerates the train by changing the voltage and frequency delivered to the motor. The inverter uses the cutting-edge silicon carbide (SiC) technology adopted by the most recent series of Shinkansen (“bullet trains”). Compared to conventional silicon (Si) power modules, the SiC power module is energy-saving because it requires no cooling fans. It also contributes to lowering noise, downsizing, reducing weight, and making maintenance easier. Our application of SiC in the inverter of an AGT system was the first in Japan.

Soft-beam Lighting Illuminates Kobe at Night

To express the warm feeling of going home where your family awaits you, the cars are outfitted with a row of lights above the front window, inspired by torch light. The lights are also intended to enhance visibility from afar and give a different look from the cars’ daytime appearance, to make the railway line look more attractive.

Individual Seats Permit More Light to Enter

Seats of the 3000 Series are separated individually, with openings under the backrest to let more light from the windows come through.

The Secret of the Luggage Holders

The luggage holders in the corners are covered with wood and have handrails. Inside this cubical space, a variety of control equipment is installed-an ingenious way to squeeze equipment into a compact area without compromising the usability of the car.

An Area for Wheelchair Users in Every Car

A section of the floor is painted, designating a space reserved for wheelchairs and baby strollers. The floor of the cars is lower than in the 1000 Series to create barrier-free accessibility from the platform to the train.

Aluminum Alloy Bodies

Because the paint on the cars’ exteriors is designed to blend well with the surroundings, aluminum alloy, which possesses superior coatability, was used for the bodies instead of stainless steel. The material was also chosen because of its good workability and the ease with which it can be lightened, in order to clear the strict weight limits of the rubber-wheeled AGT trains, where a great deal of equipment is installed in a compact space.

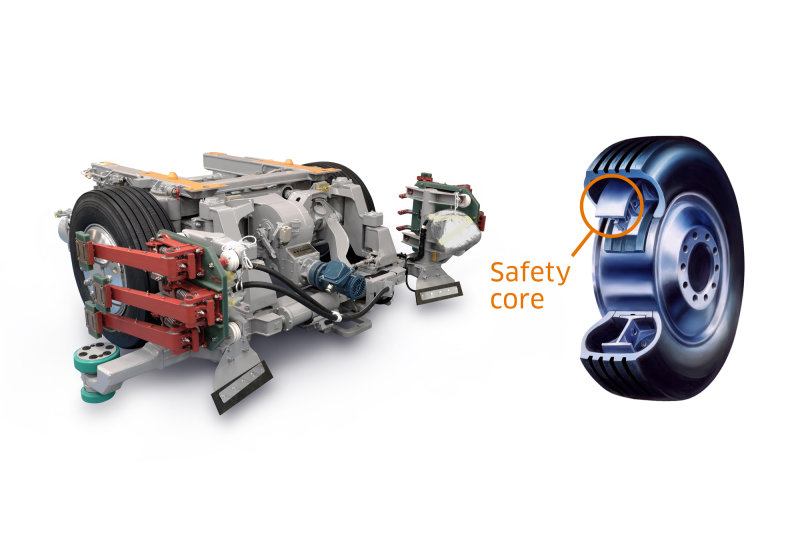

New Tire and Motor Achieve Lower Noise than the 1000 Series

Nitrogen-filled tubeless rubber tires equipped with safety cores are installed on the bogie for improved riding comfort and reduced noise. Also, the motor's cooling fan was redesigned, resulting in a 7 dB reduction in motor noise compared to the 1000 Series because of the fan’s reduced aerodynamic noise.

Domestic Bogie Engineering Section

Domestic Engineering Department

Domestic Project Division

Rolling Stock Company

Kawasaki Heavy Industries, Ltd.

Domestic Bogie Engineering Section

Domestic Engineering Department

Domestic Project Division

Rolling Stock Company

Kawasaki Heavy Industries, Ltd.

Design Section

Engineering Planning Department

Domestic Project Division

Rolling Stock Company

Kawasaki Heavy Industries, Ltd.