Environmental impact assessment of CO₂ capture technology using solid sorbent at a thermal power plant in Wyoming (U.S.)

Kawasaki has conducted assessment of the environmental impact of CO₂ capture technology using solid sorbent. The project, carried out at the Integrated Test Center (ITC) adjacent to the Dry Fork coal-fired power plant in the U.S. state of Wyoming, began in 2023 and continued for about one year.

This initiative was commissioned by Japan's Ministry of the Environmen, Government of Japan under its Development Project of Integrated Demonstration Facility and Supply Chain for Sustainable CCUS (*1) and jointly carried out by Kawasaki Heavy Industries and the Japan Carbon Frontier Organization (JCOAL).

Wyoming features wide expanses of land and abundant natural resources, which are utilized by its thriving power generation industry. The Dry Fork coal-fired power plant, which served as the evaluation testing site, is one of the power stations located there. The ITC, a technology development facility situated within the vast premises of Dry Fork, provides exhaust gas from the power plant to researchers aiming to develop carbon dioxide capture, utilization, and storage (CCUS) technology (*2). Kawasaki Heavy Industries built a 115-square-meter CO2 separation and capture technology demonstration facility (post-combustion capture [PCC] demonstration facility (*3)) for testing purposes.

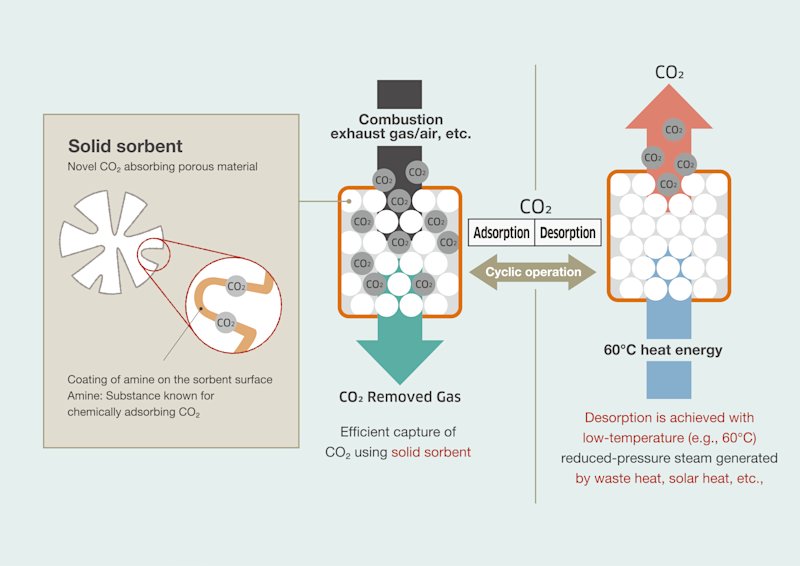

In this demonstration, we first send the combustion exhaust gas emitted from the Dry Fork coal-fired power plant to the PCC demonstration facility, which uses solid sorbent, to capture CO2. We then examine whether the exhaust gas emitted into the atmosphere following the CO2 capture contains any components derived from the solid sorbent. This involves a method in which we examine multiple locations around the demonstration facility to find out if any components derived from the solid sorbent can be detected, and if so, how much, and assess their impact on water quality and the environment.

The CO2 capture demonstration processes approximately 1,000 cubic meters of exhaust gas per hour. One of the major features of Kawasaki Heavy Industries’ PCC technology is that it can desorb CO2 at the low temperature of 60°C, while conventional methods require temperatures of over 100°C. This allows us to utilize the waste heat from the power plant and reduce the CO2 capture costs.

Kawasaki has achieved positive outcomes from this demonstration testing and environmental impact assessment. We will contribute to building a carbon-neutral society by promoting the practical implementation and widespread adoption of solid sorbent CO2 separation and capture technology.

(*1) The Ministry of the Environment Development Project of Integrated Demonstration Facility and Supply Chain for Sustainable CCUS

One of the CCUS initiatives undertaken by the Ministry of the Environment with the goal of achieving the widespread adoption of CCUS technology in society and instilling environmental awareness by 2030. To achieve these goals, the project seeks to establish commercial-scale CO2 capture technologies, as well as technologies that can effectively utilize this CO2, and create demonstration facilities and supply chains to enable their practical deployment by constructing a model for a decarbonized and sustainable society.

(*2) CCUS

The abbreviation "CCUS" stands for “carbon dioxide capture, utilization, and storage.” This technology separates and captures the CO2 found in the exhaust gas produced by thermal power plants and factories, as well as the CO2 in the atmosphere. This captured CO2 can then be used as a resource for cultivating crops and manufacturing chemical products, or be stored in stable formations underground.

(*3)PCC

Post-combustion capture. Refers to the technique of separating and capturing CO2 from exhaust gases in factories with high CO2 concentrations.