First-ever attempt in Japan to capture CO₂ from exhaust gas generated by a coal-fired power station. Initiative aimed at generating cleaner energy

Kawasaki has established a pilot-scale CO₂ capture facility that uses solid sorbent. The post-combustion capture (PCC) facility, built on the premises of the Maizuru Power Station in Kyoto Prefecture run by Kansai Electric Power Co., Inc., began operations in 2023. With the cooperation of Kansai Electric Power and the Research Institute of Innovative Technology for the Earth (RITE), we are conducting demonstration testing of the CO₂ capture system at this PCC facility.

This is the first demonstration in Japan that solid sorbent is applied to capture CO2 from actual combustion exhaust gas at a thermal power plant. We are examining the performance of our PCC technology and collecting a variety of test data in order to assess its operational stability and economic viability, with an eye towards future implementation.

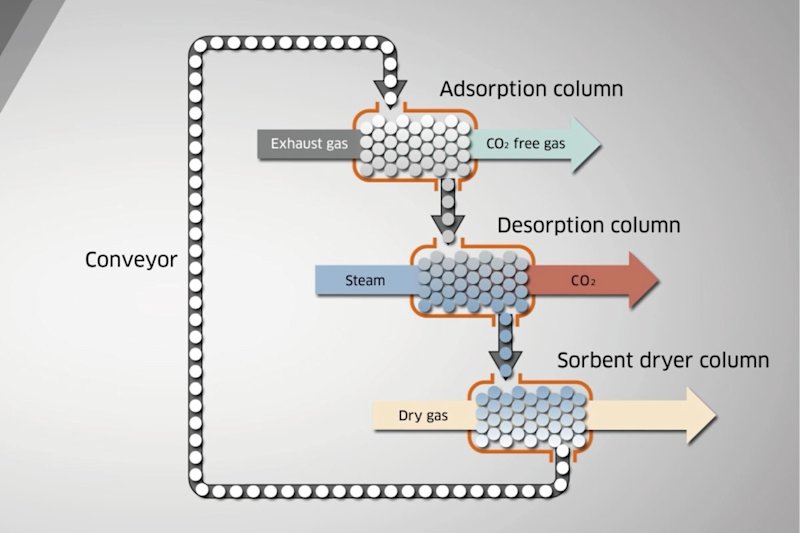

The key technoklogy adopted in the demonstration facility is a PCC moving-bed mechanism. The system consists of three columns: an adsorption column, in which the CO2 in the exhaust gas is adsorbed by solid sorbent particles; a desorption column, in which the adsorbed CO2 is extracted and collected as gas; and a sorbent dryer column, in which the moisture remaining in the solid sorbent particles is removed. Solid sorbent particles containing CO2-absorptive compound (amine) will circulate through the three columns, allowing the system to continuously capture CO2 and facilitating the addition or replacement of these particles. This system is suitable for use in large-scale plants, and widespread adoption is expected once it has been put into practical use.

During the demonstration at Maizuru Power Station, about 40 tons of CO2 are captured daily from the power plant’s combustion exhaust gas. One of the major features of Kawasaki’s PCC technology is that it can desorb CO2 at the low temperature of 60℃, while conventional methods require temperatures of over 100℃. This makes it possible to desorb CO2 by utilizing the power plant's waste heat. In addition to reducing costs, this method also allows us to establish an efficient system for facilitating the reuse of energy within the company.

This demonstration is an important step toward putting our technology into practical use. Kawasaki hopes to collect a large amount of operation data through this project and expand the scale of our facilities in order to promote the implementation of this technology throughout our society. We aim to significantly reduce CO2 emissions across our locations and contribute to building a carbon-neutral society.