Toyota × Kawasaki: Achieving carbon neutrality with hydrogen

Hydrogen is attracting a great deal of attention as a future-oriented approach to realizing carbon neutrality. Free from carbon dioxide (CO2) emissions when utilized, hydrogen shows real potential as the ultimate clean energy. Since the early 1990s, Toyota Motor Corporation has focused efforts on research and development of hydrogen technologies, and these efforts paid off in 2014 when Toyota launched the Mirai, the first-ever mass-produced fuel cell vehicle installed with a compressed hydrogen storage tank. Since 2016, Toyota has stepped up its efforts to develop a hydrogen engine as well. Kawasaki has been involved in hydrogen technology development for approximately 40 years, and, in the last decade, has focused on hydrogen’s potential as a next-generation energy. Combining the technological prowess and overall capabilities it has honed over many years, the Kawasaki Group is developing core technologies to establish an integrated hydrogen supply chain, encompassing all aspects from production to transportation, storage and utilization. What is hydrogen’s role in realizing a carbon-neutral world? This is the question that was posed to key persons working on hydrogen projects at Toyota and Kawasaki.

Note: We take steps to prevent the spread of infection, including mask-wearing and social distancing when carrying out interviews and photography

General Manager

Hydrogen Fundamental Development Div.

Hydeogen Business Field, CV Company

Project General Manager

New Business Planning Div.

Business Development Group

Assistant Manager

H2 Engine Development Group

Hydrogen System Products Development Dept.

Hydrogen System Products Development Div.

Hydrogen Buisiness Field, CV Company

Manager, Section 2

Business Development Dept.

Project Group

Hydrogen Strategy Division

Assistant Manager, Section 1

Project Promotion Dept.

Project Group

Hydrogen Strategy Division

How Toyota and Kawasaki’s hydrogen initiatives started

It was more than 40 years ago, back in 1978, when Kawasaki delivered a liquefied hydrogen rocket engine combustion test facility to the University of Tokyo Noshiro Rocket Testing Center in Akita Prefecture. Almost 10 years later, in 1987, we installed liquefied hydrogen fuel storage tanks at the Tanegashima Space Center in Kagoshima Prefecture. Since then, we have continued to accumulate knowledge about the handling of liquefied hydrogen, and in 2010, we proposed a concept for a hydrogen energy supply chain. We continue to make company-wide efforts to harness the potential of hydrogen for achieving carbon neutrality.

There’s actually a very interesting story that dates back to the time that Toyota started development of fuel cells.

It was 1992 and we had just launched a project for fuel cells using hydrogen. You might recall that it was around this time that the entire auto industry was starting to come under pressure to address energy issues, such as the adoption of the Zero-Emission Vehicle (ZEV) requirement by the State of California in 1990.

I heard from a senior colleague that in 1994, Kenya Nakamura*1 wrote a letter to Masanao Shiomi, one of Toyota’s managing directors at the time, and set out the vital importance of hydrogen, writing that, “The combination of nickel-metal hydride batteries and fuel cells may well be the final piece of the puzzle.”

*1: The designer of the first Toyota Crown and master engineer who laid the foundations for Toyota’s development and production systems

Back around 2000, it was briefly mentioned in the Kyoto Protocol (adopted at COP3), but otherwise the issue of CO2 emissions wasn’t really on people’s radars. Even back then, though, was your company already involved in developing hydrogen technologies?

Yes. Today we’re engaged in discussions that look ahead to 2030 or even as far forward as 2050, but already back in the 1990s, our predecessors had an inkling of what the future held in store.

I joined the company in 2000 when there were two major trends in seeking to make vehicles more fuel-efficient for the 21st century: hybrids, as epitomized by the Prius, and diesel vehicles. We were also working on alternative fuels, and fuel cells are of course an important technology in that field. At Toyota, one of our beliefs is that “Environmentally friendly vehicles can only truly have a significant positive impact if they are widely used,” so we were all trying our best to somehow develop a mass-producible vehicle.

How the automotive and heavy industries view hydrogen today

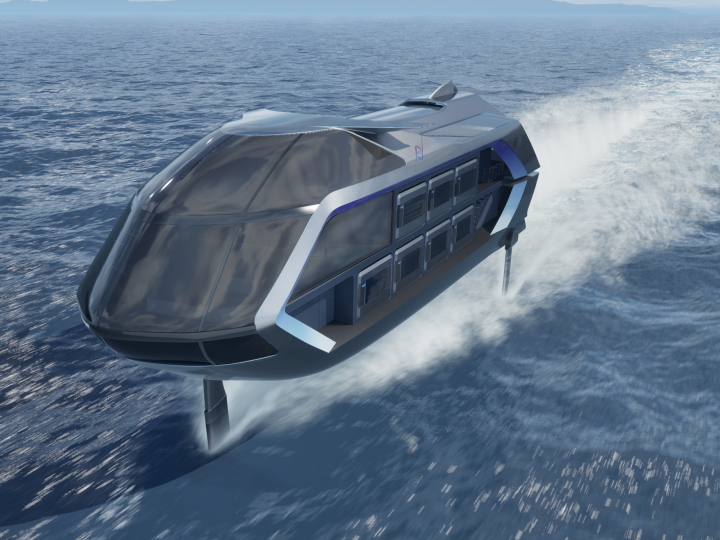

Kawasaki is developing its own technologies in the four-phase processes of hydrogen: production, transportation, storage and utilization. For utilization, we have taken the hydrogen combustion technologies that we originally developed for gas turbines and are trying to adapt them for use in aircraft, shipping, and motorcycle engines, so that they can be applied to our various products.

In the areas of production, transportation and storage too, with the support of the Japanese and Australian governments, we are working in collaboration with six other companies—Iwatani, Shell Japan, J-POWER, Marubeni, ENEOS, and Kawasaki Kisen Kaisha—to build a hydrogen supply chain. Our efforts include a world-first demonstration project involving the production of hydrogen from abundant brown coal (lignite) in Australia and the transportation of liquefied hydrogen to Japan in the world’s first liquefied hydrogen carrier Suiso Frontier.

In terms of usage, hydrogen can be used as is, or as hydrocarbons or electricity created from hydrogen. These different forms of use are suited or unsuited for different purposes, so the optimal solution will depend on the end use or application.

Take fuel cell electric vehicles (FCEV), for example. They are one way that everyday people can use hydrogen. The hydrogen engine we’re working on currently is another example. The range of available options has continued to expand over the past decade, and we still don’t know which one is best. That’s why we believe it’s important not to declare “This is the one,” but to instead carry on our work without narrowing down the options. One thing that we can say for certain is that it’s impossible for one company alone to create a hydrogen-based society if, as we believe, we need to pursue a multi-pathway approach.

The Hydrogen Council was launched in 2017 with 13 companies as founding members, and today the council has grown to have a membership of more than 140 companies. Toyota has been leading the foundations for this organization, serving as the inaugural co-chair.

Many different companies realized that they needed to do something to be ready for the future and that they needed a forum for discussion. That forum became the Hydrogen Council. The Japan Hydrogen Association (JH2A) also provides such a function. These are forums where companies that need assistance or possess technology that can help others can get together and exchange opinions.

What is the Japan Hydrogen Association?

The Japan Hydrogen Association (JH2A) is an organization that seeks to promote the formation of hydrogen supply chains, through global partnerships in the hydrogen sector and open, cross-industry initiatives. It was established in 2020 with the purpose of building a hydrogen society at an early stage through the realization of social implementation projects.

In just over two years since JH2A was launched, the organization has grown from a membership of 88 companies to more than 300 today. As a private-sector-led organization, it focuses on what is needed for future social implementation and commercialization, and works backwards from there.

What is unique about this organization is that it provides a forum for companies that would normally be rivals in, for example, the production of water electrolyzers (a method of producing hydrogen by electrolyzing water), to come together and exchange ideas. It really is effective in bringing companies together around a single table. Another unique feature of JH2A is that it tries to find solutions that connect upstream and downstream sectors, from the power companies that supply electricity, through to the supply chain that produces and delivers hydrogen from this electricity, and end users.

If I could add one other thing—people tend to worry that hydrogen is dangerous or that it will actually increase costs. We need to overcome such concerns by working together and sharing our collective wisdom. In this sense, we expect JH2A to fulfill this function. It has the potential to bring together companies that would normally be competitors and lets them brainstorm potential collaboration for achieving their goals.

Hydrogen kickstarts Toyota-Kawasaki collaboration

In 2021, Toyota used hydrogen produced from brown coal, or lignite, an untapped natural resource from Australia, for some of its fuel in the Super Taikyu race series. This Australian hydrogen was produced and air-transported by J-Power, with Kawasaki and Iwatani working together to transport it to the Suzuka Circuit.

I really get the sense that the Super Taikyu series is a brilliant showcase for hydrogen technologies. Normally, hydrogen is something that people can’t really see or feel, but hydrogen-powered mobility zooming around the Super Taikyu circuit makes it real for everyone who could see it. It really supercharges awareness of hydrogen among the public, and it’s something that Toyota could do.

Almost all customers are familiar with Toyota products. That’s why Toyota has such a vital role to play in boosting public awareness about what hydrogen is and making people more aware of its safety and so on.

The great thing about automobiles is that they are such a familiar presence for everyone. If cars were to run on hydrogen, everyone would try to picture where you can fill up with hydrogen, where it is produced, and who transports it. That’s why cars can play a role in helping people to understand and accept how hydrogen can become a part of daily life.

If we simply ran cars using hydrogen engines, it wouldn’t leave much of an impression on people, but showcasing hydrogen-powered engines in the Super Taikyu series makes it easier to appreciate how hydrogen is produced and transported. That’s how we can start to get people used to having hydrogen in their lives.

Another thing that strikes me from watching the Super Taikyu races is the speed of development. The first demonstration test vehicle was a Corolla implemented with a hydrogen-powered engine. Since then, you have made efforts to increase the cruising range and are now working on storing liquefied hydrogen onboard. You are jumping from one development to the next with truly amazing speed.

For the Super Taikyu series, we implemented a cycle where the “seeds” planted in the vehicle for the first race were immediately collected and transplanted to incorporate improvements in the car to be used in the next race a couple of months down the line. This is what we refer to as “agile development.” Although the Super Taikyu vehicles are racing models, they actually include many technologies that have commercial potential, and the experience we gain from racing is put into the development of commercial vehicles.

It’s really amazing that you’re able to incorporate improvements within the space of two or three races. With the building of an energy supply chain, a timeline of at least 10 years will be needed. It’s completely different from the lead times for car manufacturing, but I think we should take note of the sense of speed and urgency that characterizes Toyota’s development activities.

On the other hand, though, what Kawasaki does in taking a long-term perspective also comes with its own set of difficulties and challenges. Whether it’s LNG or hydrogen, you stay focused on what may be a far-off goal and keep moving forwards. That presents challenges that we don’t experience in our work, and it probably can’t be achieved without a clear vision, concept, and sense of mission.

In the case of LNG transport vessels, as well as other areas, we have predecessors at the company who found success by believing firmly that “This is the answer” and pursuing that belief. Given that we deal with product lineups over 10 and even 20-year time spans, it is the successes of our forebears that give us the confidence to say, “Don’t worry, this is the right way.”

Incidentally, for the 2023 season of the Super Taikyu series, we are planning to cooperate with Iwatani and J-Power to transport hydrogen from Australia using the liquefied hydrogen carrier and deliver it to the Toyota team.

We will race using a GR Corolla fitted with a hydrogen direct injection engine powered by Kawasaki-supplied hydrogen. This season, we will introduce a racecar fueled by liquefied hydrogen, and I hope people will take notice and look forward to it!

Carbon neutrality promises a bright and happy future for all

Our goal is to realize carbon neutrality. Hydrogen is an indispensable part of achieving that goal, but we should always remember that it is just one part of a bigger picture. We need, therefore, to look at hydrogen in the context of other technological developments.

This is because optimal solutions will likely change as peripheral technologies evolve. Carbon Capture and Storage (CCS) and Direct Air Capture (DAC) are two good examples of technologies that have the potential to bring about change if they can become more cost-effective and widespread. A significant breakthrough in how renewable energies are used would also have an impact. At Toyota, we are also working on carbon capture technologies, and we recognize that it will be essential to have a good technology mix to reach our goals. We shouldn’t be simply saying that coal and oil are bad; there is absolutely no need to narrow down our options for standing up to our real “enemy” of CO2.

To add to that—Japan is an island nation, with few natural resources and a challenging geological environment, but that’s exactly why I believe there must be something we can offer the rest of the world. I heard from an acquaintance that people overseas were initially doubtful about the transportation of coal and LNG, questioning why it needed to be transported in the first place. For resource-poor Japan, however, we have no option but to do so.

Kawasaki has consistently taken the lead in developing such energy transportation technologies, and by constantly refining and improving them, you have succeeded in spreading their use around the world. You could say that the unique challenges and circumstances in Japan have given rise to a solution that has the power to make the world of tomorrow a better place. I think that you are doing exactly the same in response to the challenge of transporting hydrogen, and through the combination of Kawasaki’s history and experience, you will surely be successful.

As I just mentioned, back in 2010, when Kawasaki started full-fledged work on liquefied hydrogen transportation and storage technologies, many people overseas were saying that it wasn’t possible or didn’t make good business sense. We were told that hydrogen could be made in any country using water electrolysis and there was no need for it to be transported. Today, however, people are asking to visit the Suiso Frontier, which is the world’s first liquefied hydrogen carrier and successfully completed a demonstration test to carry liquefied hydrogen by sea between Japan and Australia.

So you were right all along to believe in the option of transporting hydrogen. Incidentally, if we were asked what the key to creating a hydrogen society will be, we may be tempted to say that it’s technology. However, I believe the most important thing is actually to confirm whether everyone is indeed aiming for a hydrogen society. There could be many people who still perceive the path to carbon neutrality and a hydrogen society as somehow dangerous or requiring sacrifices. If we can think of the goal we should aim for as being a bright and happy future for all, then I believe we will naturally start heading in that direction.

To that end, the first step is to promote a proper understanding of the situation. What’s interesting about carbon neutrality is that, on the one hand, it’s a difficult challenge that must be tackled at the national level, but on the other hand, it’s also an issue that even small children can do something about. Simple things like switching off the electricity or recycling are good for the planet and lead to a better future. If everyone realizes this, they can find happiness in thinking, “I did something good for the planet today.” The accumulation of these small actions can help to change society.

Coming up with ways to achieve carbon neutrality and a hydrogen society is not something that anyone, not even the cleverest person, has an immediate answer for. We mustn’t expect one single person to find the answer. Rather, all of us should think together about what needs to be done. Unless we collect accurate information, think together, and try to find the right way forward, we will not achieve our ultimate goal.

Although we all share the same goal of carbon neutrality, the “right way forward” may be different depending on the country, region or community. The speed at which we realize our goals will also vary. I think that mutual respect is very important as we strive together to reach this goal.

The reality is that no one has achieved carbon neutrality yet. There is still no definitive solution, and even if there were, it would be different depending on the country, region and local culture. That’s why we must propose solutions for realizing carbon neutrality that are tailored to each region and community.

Shared passions and common goals

As a company, Toyota is good at using hydrogen. What we look to Kawasaki for is the transportation of hydrogen at a lower cost, so that we can increase the energy options available.

We will definitely provide the hydrogen, so please continue to increase your usage of it (laughs). Hydrogen use is not limited to vehicles, but has a range of applications, from various mobility scenarios to power generation and use in manufacturing plants. I hope we can continue to enhance our respective technologies and build markets for them.

We are already collaborating in the areas of transporting and using hydrogen through the Super Taikyu series. With Kawasaki manufacturing motorcycles, I would expect that there is even more we could do together, including the sharing of parts and components.

To achieve carbon neutrality, it will be vital to make progress in all phases of the value chain, from manufacturing to transportation, storage and use. Both Toyota and Kawasaki recognize the need to move beyond chicken-or-egg-type discussions because we share the same ultimate goal. I hope that, as colleagues and friends inspired by the same passion and ambition, we can work together for a carbon-neutral future, in a symbiotic relationship like flowers and bees.