Kawasaki’s Collaborative Hydraulic Equipment Business with the U.K. Spans a Quarter Century

In 1994, Kawasaki established its first development and manufacturing subsidiary in Europe, Kawasaki Precision Machinery (UK) Ltd. (KPM [UK]), which develops, manufactures and supplies hydraulic equipment and devices. Twenty-five years have passed, and KPM (UK) is now a prominent international supplier of hydraulic motors and pumps. In this issue of SCOPE, we bring you a story featuring how Kawasaki and the U.K. have cooperated with each other as “Joint-Growth” partners, and what the leaders’ visions are for the future of the business.

Kawasaki’s First Development and Manufacturing Base in Europe

The U.K. has long played an instrumental part in Kawasaki’s businesses. When Kawasaki was first founded as Kawasaki Tsukiji Shipyard in 1878, and also when the company embarked on the manufacture of rolling stock in 1906, it was technologies imported from the U.K. - the world’s leader in manufacturing - which supported those endeavors.

Even today, the British influence is evident in Kawasaki businesses. Hydraulic equipment and devices supplied by the Precision Machinery & Robot Company is one such example. KPM (UK) has been manufacturing and marketing these hydraulic motors and pumps at the Plymouth site in the U.K., as well as providing services in Europe and elsewhere since 1994.

The company, which celebrates its 25th year of operations in 2019, was originally a hydraulic motor plant owned by an American company, Vickers, Inc., which Kawasaki acquired at the end of 1993. Long before the acquisition, a relationship existed between Kawasaki and Vickers. It began in 1963, when Kawasaki decided to apply to their domestic products hydraulic motor technology used in Staffa hydraulic radial piston motors for marine vessels, which the Vickers plant had been manufacturing. Subsequently, KPM (UK) was established, with operations commencing in January 1994.

The decision to acquire the plant, establishing Kawasaki’s first manufacturing base in the U.K., as well as in Europe, was based on the corporate motto “Joint-Growth” (growing together), proposed by Hiroshi Oba, the then president of Kawasaki.

The Japanese portion of the production of Staffa motors was later transferred to KPM (UK), making the subsidiary Kawasaki’s sole manufacturer of Staffa motors. Today, Staffa motor is one of two pillar businesses of KPM (UK). The other is the manufacture, assembly, customization, sales and marketing of axial piston motors and pumps, which are developed in Japan and exported to Europe and elsewhere.

The scope of applications of these products is wide-ships, construction equipment, agricultural equipment, manufacturing machinery, and many more. Today, they are used worldwide, proving that the collaborative business between Japan and the U.K. is seeing great outcomes a quarter century later. What are the types of progress has “Joint-Growth” achieved, and where is the collaboration going?

Three Main Products of KPM (UK)

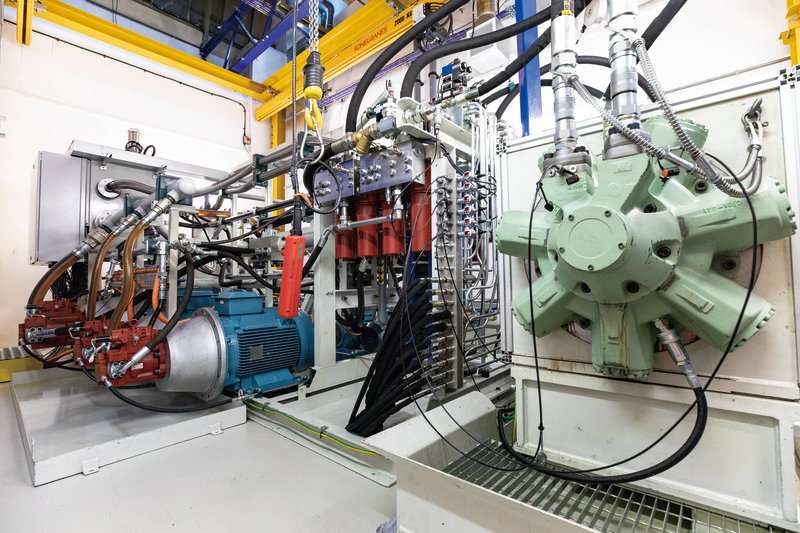

A radial piston motor developed in the U.K. in 1955, characterized by low-speed, high-torque operation, and robust durability. Although the main applications for the motor include winches and the steering gear of ships, it is now being applied to injection molding machinery for synthetic resins, metal press machines, and tunnel boring machines as well

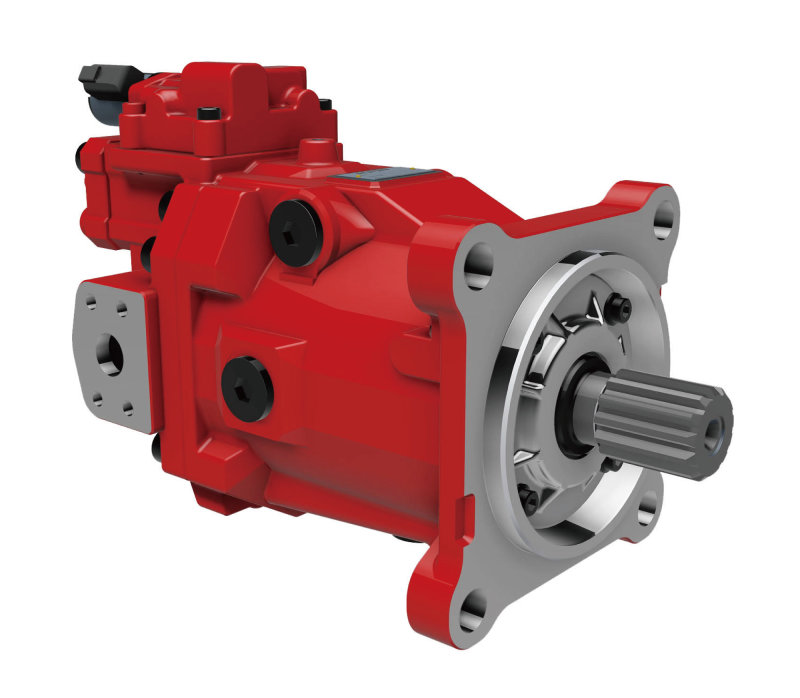

Kawasaki’s axial piston pumps are developed based on its proprietary technologies. Outfitted with hydraulic motors, the pumps are applied to a wide variety of machinery, including construction, agricultural, and manufacturing equipment

Axial piston motors of the same type as the pumps, in which the hydraulic cylinders are configured parallel to the rotation shaft. These are high-speed, high-torque, variable-pressure motors that accommodate downsizing, and are used for the same purposes as hydraulic pumps

Staffa Motors: Originated in the U.K., Evolved via the Kawasaki Method

Plymouth is a port city on the southern coast of Devon County in England, located 300 km south-west of London, with a population of 264,200. It is known as the port from which the Pilgrim Fathers departed for the United States aboard the Mayflower in 1620. It is also known as a port which served as a base for Sir Francis Drake, an English admiral, and it continues to be a major base for the British Navy. After the industrial revolution and up to the 1950s, the city flourished as a shipbuilding center.

The 280-member headquarters and plant are situated 10 km north-west of Plymouth’s center, along the River Tamar which flows into Plymouth Sound, a bay on the English Channel.

The plant was first built in the latter half of 1950s by a British machine tool manufacturing firm. The firm was later sold to another company, which decided in 1982 to produce hydraulic radial piston motors - the Staffa motor.

Development of the Staffa motor dates back to 1955. It became especially popular in the shipbuilding sector because of its remarkable features: low speed, high-torque design; low occurrence of failures; low maintenance; and robust durability. Deck machinery, offshore winches, plastic injection molding machines, and drill rigs are among the main applications of the motor.

The company which had owned the plant was renamed twice during merger and acquisition, and the present owner, KPM (UK), is the world’s exclusive developer and manufacturer of Staffa motors. It is a top-selling brand in hydraulic motors for marine and industrial applications. KPM (UK) boasts a production output of 7,500 units per year, which is achieved through a two-shift production system. This product accounts for 35% of its total sales.

Steve Clarke, Product Development Manager, who leads research and development of Staffa motors at KPM (UK), comments, “Our biggest mission is to maintain our No.1 status in the marine machinery market, both today and in the future. The Staffa motor is often considered to be a product built on an obsolete technology, product built on an obsolete technology, so investments in new research and development are imperative if we are to maintain superior market competitiveness.”

The “Joint-Growth” collaborative approach underpins the never-ending improvements and launch of new motors.

Clarke states, “Staffa motor parts that were developed in the 60s and 70s can be replaced with new parts redesigned by Kawasaki, and new mechanical motion detection and control systems can be integrated. This will show that the Staffa motors’ superior reliability ensures operation for years to come, and that combined with Kawasaki’s quality, efficiency, and usability, it is a motor with remarkable benefits rolled into one.”

At the plant’s testing section for new products, operational tests are being conducted for a high-speed Staffa motor, which will be a dramatic improvement of one of its main features. KPM (UK) also is positioning the new Staffa motor to accommodate needs in industrial machinery markets other than marine applications, such as injection molding machinery for synthetic resins.

Localizing and Optimizing Japan-Made Pumps/Motors in the U.K.

KPM (UK) takes a different marketing approach to hydraulic axial piston pumps and motors than it does to Staffa motors. While Staffa motors are developed and manufactured by KPM (UK) and exported from the U.K. worldwide, axial piston pumps are developed by Kawasaki in Japan, and core parts (rotary group) are exported to KPM (UK) under the Kawasaki brand. The main role of KPM (UK) in this business, which accounts for more than 50% of its total sales, is therefore manufacture and assembly for its customers.

Because axial piston pumps and motors are compact and come in a variety of types, they are applied to a wide range of equipment-from excavators (their main application) to mobile construction machinery (other than excavators), mobile agricultural machinery, and other industrial machinery. KPM (UK) is therefore tasked with meeting diverse customization and localization needs. The number of sales is about 5,000 pumps and 3,000 motors per year for excavators, and about 18,000 pumps for non-excavator machinery.

John Glover, Application Engineering Manager at KPM (UK), who is in charge of the mobile product application engineering, comments, “It is very important to ascertain the specific requirements of our customers, and to meet those needs as much as possible by communicating closely with the design division in Japan. Currently, we are increasing our product portfolio by introducing new products.”

U.K.-based Kawasaki Brand Accommodates Customers Around the World

Another factor that contributes to achieving “Joint-Growth” is the sharing of knowledge in a highly transparent manner among the design divisions at both Kawasaki in Japan and at KPM (UK) and the sales force in the U.K.

Regarding this three-way collaboration, John Boote, Senior Manager for Sales & Marketing at KPM (UK) comments, “Our prominent customers in the construction and agricultural machinery sectors are Volvo of Sweden, JCB of the U.K., John Deere and New Holland of the United States, and other multinationals. Their diverse requirements are accommodated not only through cooperation among engineers at KPM (UK) but also by involving the development divisions in Japan, so as to collaboratively resolve challenges. This cooperative relationship is a significant advantage in our growth.”

KMP (UK) made a leap forward in its hydraulic pump and motor business by securing a major contract for Volvo’s construction machinery in the year 2000. Boote explains that the collaboration between the design divisions in Japan and the U.K. played a vital role in such sales activities.

For the last several years, KPM (UK) has been promoting its products through advertisements featuring the Kawasaki brand image, which have proven effective. Kawasaki is well-recognized as a cutting-edge global leader in two-wheelers and high-speed trains in the EU and nearby markets, and this high-profile image serves to assure potential customers that Kawasaki will supply hydraulic products that best meet their requirements, just as it does in the motorcycle and rolling stock sectors.

Kawasaki Precision Machinery (UK) Ltd.

Optimal Solution Achieved by Dividing Responsibilities and Coordinating Japan and the U.K.

Although KPM (UK) seems to operate two separate businesses (U.K.-made Staffa motors and Japan-made hydraulic pumps and motors), Glover, who is in charge of design in the hydraulic pump and motor division, says, “I communicate with my counterpart in the Staffa motor division, Steve (Clarke), on a daily basis. That’s because although we are in charge of different projects, we have the same procedure for coordinating the sales and the manufacturing divisions.”

Martin Cunniff, Operations Director, who oversees all business operations at KPM (UK) comments, “In the manufacturing of hydraulic pumps and motors, assembly can now be accomplished by following the instructions on the LCD monitor in front of you. We are currently introducing the same systems for manufacturing Staffa motors.”

Such advancement in the manufacturing process cannot be achieved merely by applying Japanese production systems to those in the U.K. KPM (UK) is now gearing up for the fourth industrial revolution, known as “Industry 4.0,” whereby high-mix, low-volume production of high-value-added products can be done in a timely and highly-efficient manner by utilizing the Internet of Things (IoT) and artificial intelligence (AI). This “smart manufacturing” is being explored particularly by German and other European companies.

Cunniff elaborates, “European manufacturers - our customers - are working on reforms to achieve Industry 4.0. We, too, are upgrading not only our production systems but also the entire operational system.”

These initiatives at KPM (UK) are communicated to Japan. Masaki Onishi, who assumed the post of Managing Director at KPM (UK) in April 2018, explains, “We do have an agreement that in terms of product development, the U.K. team leads the Staffa motor projects, and the Japanese team, hydraulic pumps and motors. However, the people in charge of developing these products in Japan and the U.K. are communicating closely. Looking back over the last 25 years, we pursued ‘Joint-Growth’ by taking approaches that were suitable for each country individually and, at the same time, made efforts to coordinate with each other. We would like to apply this procedure to Information and Communication Technology (ICT) initiatives and human resources development, as well as to management, in order to achieve effective collaboration.”

140 Years of Kawasaki’s Tie with the U.K.

Since its founding 140 years ago, Kawasaki has had a connection to the U.K.

It was British technologies which supported the launching of several of our new businesses in the initial years. In conjunction with Rolls-Royce, we have been developing turbofan engines for passenger aircraft and gas turbines for ships, as well as supplying tunnel boring machines for the Channel Tunnel which opened in 1991, to name a few. And for a 1996 ceremony in Japan marking Kawasaki’s centennial of incorporation, then prime minister Margaret Thatcher gave a special lecture.

Such history makes the establishment of KPM (UK) as Kawasaki’s first development and manufacturing base in the U.K. and Europe 25 years ago the natural outcome of such a long-time relationship.

General Manager

Kawasaki Precision Machinery (UK), Ltd.

Japan-U.K. Collaboration to Continue, to Keep Achieving “Joint-Growth”

KPM (UK) marked its 25th year of operations in 2019. We have undergone significant changes in the last quarter century. For example, our current product portfolio is very different from that of 25 years ago. Initially, we only had Staffa motors, but Kawasaki’s hydraulic pumps and motors were later added, and we now have many variants of Staffa motors as well.

Over the years, sales have increased with fluctuations; we experienced a major dip in 2009 resulting from the global financial crisis, and a subsequent sharp recovery in 2010/2011. This experience has driven us to diversify our product offering, by increasing customer value and growing our industrial and agricultural market share.

Our primary clients, namely European and American manufacturers, are focused on transitioning to Industry 4.0, compelling us to accommodate the ensuing changes. Although some analysts view Brexit as being a potential business opportunity, as opposed to being merely a risk, it is still a factor which necessitates changes on our part.

At such times, we must focus on employee engagement and development, because unless employees are equipped to transform with these changes, we will not be able to keep up. This is aligned with Kawasaki`s “Changing forward” cultural reform. I have a slogan, “develop people first, products next.” We are offering training programs geared to all levels of employees and for all types of work.

We have been awarded accreditation against the Investors in People Standard, the international standard for personnel management, given to companies which make significant investments in personnel development.

Kawasaki`s Japanese management culture has supported KPM (UK)’s engaging working environment.This has contributed to creating an attractive workplace and providing a high retention rate of employees. Other companies tend to be less focused on long-term personnel development.

Looking back, we can say that our favorable relationship with major clients like JCB and Volvo is attributable to Kawasaki’s superior brand power, technology, and products. Kawasaki, in turn, respected the superiority of Staffa motors’ brand power, technology, and products.

Current MD, Masaki Onishi, is someone who experienced an interesting turn of fate, as he began working for KPM (UK) as an engineer 20 years ago, just when KPM (UK) decided to supply Kawasaki’s hydraulic products. We hope to continue achieving “Joint-Growth” in the upcoming period of change by working closely together.

Kawasaki Precision Machinery (UK) Ltd.

Kawasaki Precision Machinery (UK) Ltd.

Sales & Marketing

Kawasaki Precision Machinery (UK) Ltd.

Kawasaki Precision Machinery (UK) Ltd.

Kawasaki Precision Machinery (UK) Ltd.