In the Near Future, Hydrogen Power Generation Will be a Trump Card in Reducing CO₂ Emissions

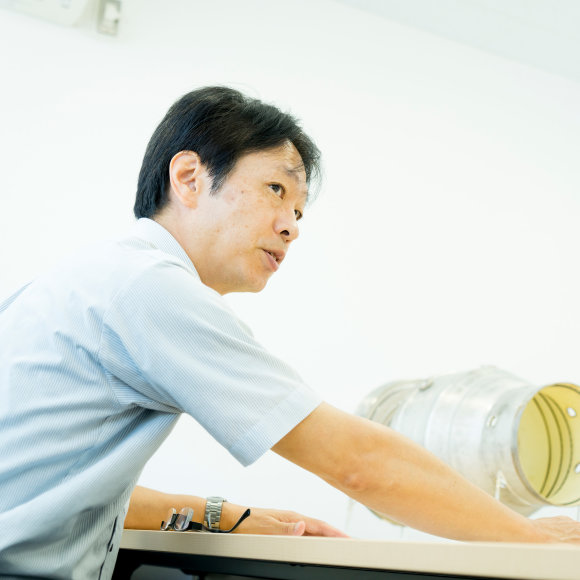

Hydrogen is a clean energy with a key role for the future. Using hydrogen as fuel to generate electricity, hydrogen gas turbines are the focus in order to realize a hydrogen-based society. These stories describe the generation of hydrogen power as addressed by Kawasaki, a company with abundant achievements in the development and production of gas turbines utilizing natural gas. We interviewed Motohiko Nishimura, Associate Officer in Hydrogen Project Development Center.

The Idea of Storing Energy in the Form of Hydrogen

Hydrogen is the ultimate clean energy source. Like electricity, hydrogen is a secondary energy source, but the biggest difference between electricity and hydrogen is that hydrogen can be transported over long distances and stored. By contrast, it is a general principle that electricity must be used immediately upon being generated. To this end, large-scale power system lines must be constructed in order to transmit the electricity to the areas where it is consumed, and it is impractical to transmit electricity over very long distances such as from overseas countries to Japan. Furthermore, the electric power stored in batteries declines continuously over time due to natural discharge, whereas hydrogen can be stored for long periods in tanks, as a result of which hydrogen has high temporal flexibility of storage. This high degree of spatio-temporal freedom is one of hydrogen’s biggest advantages as an energy source.

Hydrogen Gas Turbine TechnologyCan Make a Huge Contribution to Reducing CO2 Emissions

Due to the launch of fuel-cell vehicles, the utilization of hydrogen as a fuel for automobiles is attracting a great deal of attention. When fuel-cell vehicles and electric vehicles are compared, the driving range of the former is over five times greater than that of the latter. Moreover, it takes several hours for an electric battery to charge, while a hydrogen fuel cell can be fully charged in three minutes.

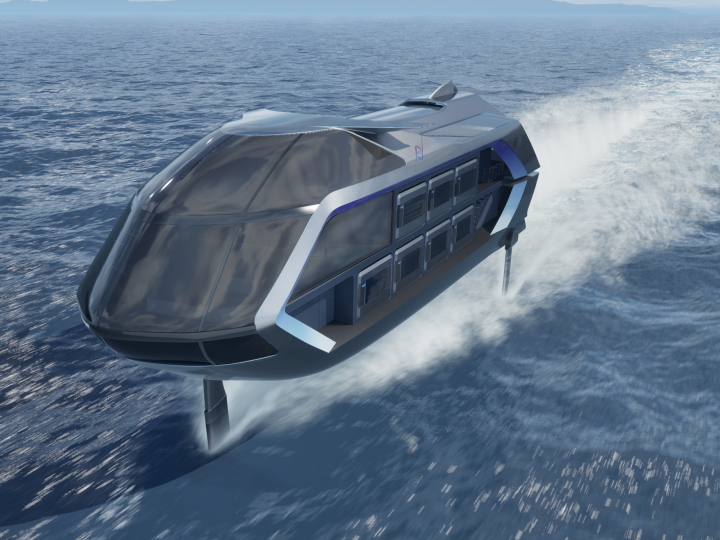

At power stations where electricity is generated, a huge amount of energy is used. How would the situation be if the fuel for power stations were hydrogen? In that case, we would achieve immediate progress in reducing CO2 emission. For example, in the case of using the hydrogen carrier ships we envision to transport hydrogen, just two tanker loads of hydrogen would supply enough fuel to power three million fuel-cell vehicles. And if hydrogen gas turbines were installed at a large-scale power plant (1GW), the same volume of hydrogen could be used. So the impact of utilizing hydrogen for power generation could be very large. In the future, if the hydrogen supply volume could be increased so that hydrogen power generation would become a mainstream power source, this situation would tend to drive down hydrogen costs, which would also lead to a reduction in fuel costs for fuel-cell vehicles.

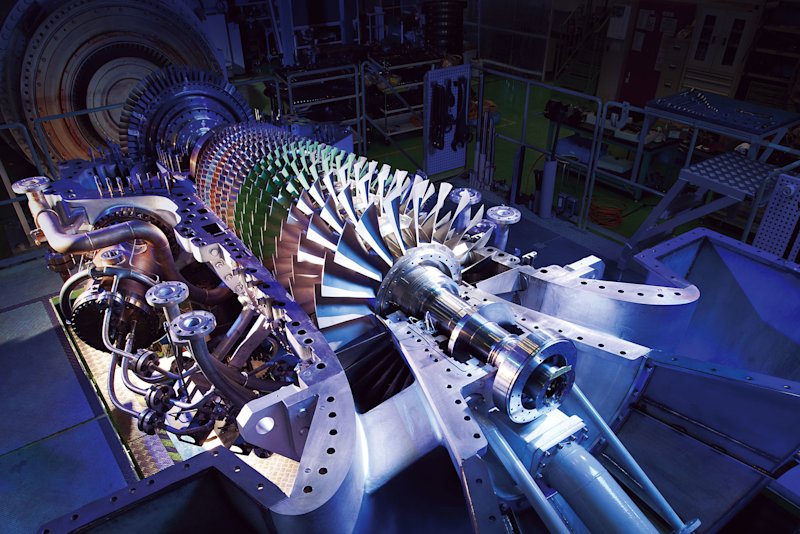

At Kawasaki, we have a long history of developing and manufacturing natural gas fueled gas turbines. Gas turbines are extremely versatile for use in generating electricity because the output of the turbines can be adjusted across a very wide range. Utilizing of this characteristic in the power generation field allows gas turbines to make a huge contribution to reducing CO2 emissions. Therefore we are currently working on the development of hydrogen-fueled gas turbines.

Resourcefully Managing Factorsthat are Conflict with Each Other

The difference between the conventional and hydrogen gas turbines is in the combustor. Kawasaki chose not to design a single-fuel combustor, but instead to proceed with the development of a combustor capable of burning natural gas, pure hydrogen and mixed fuel. However, it requires a cutting edge technology to burn pure and mixed fuel flexibly without causing failure or malfunction. This is because there are three major conflicting factors, combustion stability, burnout prevention and increase/decrease in the emission of NOx (a kind of air pollutant), that all need to be taken into account when changing mixture ratio of hydrogen and natural gas. It is very difficult to design a combustor with specifications that balance each of these factors and keep them all within their regulated values. In order to realize this goal through iterative improvements, we are performing analysis using computer simulations, trying out various designs, and bringing the combustor closer and closer to its ideal form.

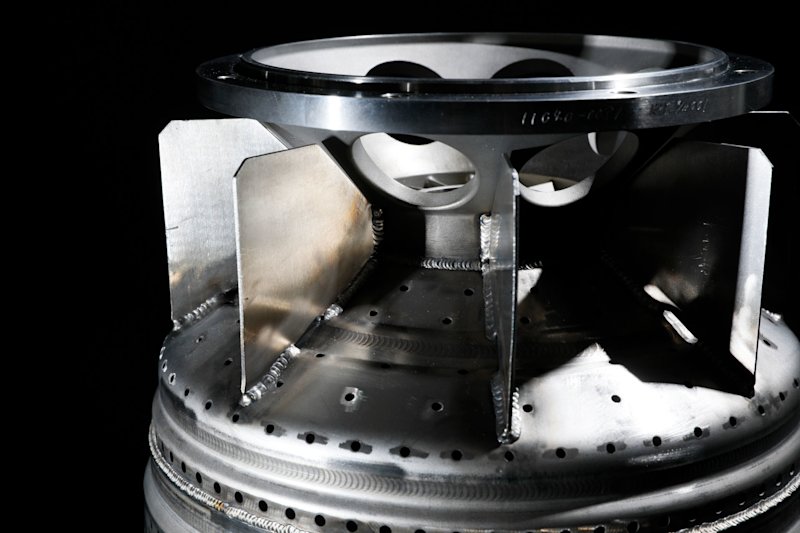

The burner is partially modified to be capable of fuelling any concentration of hydrogen-natural gas mixture, as well as pure hydrogen

A SocietyWhere We Use Hydrogenin our Daily Lives isJust Around the Corner

We receive many inquiries from other companies and factories along the lines of, “We wish to reduce our CO2 emissions; can you develop a hydrogen gas turbine to help us do this?” or “Can’t we use hydrogen with an existing gas turbine?” For example, electricity costs can be reduced by generating electricity in house using hydrogen produced as a byproduct of various factory processes. Today many of our customers both in Japan and overseas are seeking to take advantage of such possibilities.

In fact, we have established a project to begin demonstrational operation using a wet method combustor in Kobe from the start of 2018. We are planning to generate electricity by burning hydrogen and to provide this electricity to neighboring public facilities. Moreover, as gas turbine power generation can provide heat too, this project will be designed “to supply combined heat and power,” and it will be the world’s first trial of such a system in an urban setting.*1

*1: We are planning to conduct this demonstrational operation in Kobe as part of “Development of Smart Community Technology by Utilization of Hydrogen CGS,” a 2015–2017 New Energy and Industrial Technology Development Organization (NEDO) Task-Setting Type Industrial Technology Development Subsidized Project

With this technology, the fuel is divided into small amounts by ejecting from tiny nozzles roughly the diameter of the core of a mechanical pencil. We call this next-generation type burner technology “Micromix”

The Birth of a New Technology Featuring“7 Times”Flame Propagation SpeedPlus High Combustion Temperature

Hydrogen burns with a flame velocity about 7 times faster than that of natural gas and also at a higher combustion temperature. For this reason, technically, burners that use hydrogen need to overcome a range of problems such as fuel nozzle burnout, unstable combustion, and increasing NOx emission. In practice, this means that advanced technology is required in order to develop a combustor that can cope with the characteristics of hydrogen combustion.

For instance, in order to protect the fuel nozzle from the high flame temperature, the nozzle is coated with a ceramic. Also, in response to the issue of increasing NOx emission with higher flame temperature, we inject water to lower the flame temperature, but in fact this worsens the fuel economy. So we developed pure hydrogen fueled Dry Low NOx combustion technology as a totally new idea to overcome this issue. The principle is to subdivide the fuel and eject it from tiny nozzles roughly the diameter of the core of a mechanical pencil, so that the fuel burns in a “microflame.” As a result, we call this technology “Micromix.” With the Micromix combustor, it is possible to burn 100% pure hydrogen while suppressing NOx emission without water injection. As a result, the realization of CO2 zero-emission power generation is now just around the corner.*2

*2:The results of the present research were obtained based on the following research. In FY 2014 and 2015, this research was conducted as a Cross-ministerial Strategic Innovation Promotion Program (SIP) and “Energy Carrier” project supported by the Council for Science, Technology and Innovation (CSTI) (Funding agency: JST). Since FY 2016, this research has been conducted as “Research and Development of Hydrogen Gas Turbine Combustion Technology,” a Hydrogen Utilization Leadership Research and Development Project—Large-Scale Hydrogen Utilization Technology Research and Development, an outsourced project of the national research and development corporation New Energy and Industrial Technology Development Organization (NEDO).

“Make it Possible to Do What Couldn’t be Done”

The thing that has been most important to me ever since I was a young engineer is “to make it possible to do what couldn’t be done.” I believe this is a very important consideration from the standpoints of differentiating Kawasaki from other manufacturers and also of how we respond to the market’s needs. Today we are increasingly involved not only with people inside and outside of the company in Japan but also internationally. Since the creation of the hydrogen supply chain is such a huge and challenging project, we wish to act in partnership and cooperation with concerned government agencies and corporations spurred on by our wish to make progress toward the realization of the hydrogen society.

Deputy General Manager

Hydrogen Project Development Center

Corporate Technology Division

Kawasaki Heavy Industries, Ltd.