Fujita Health University and Kawasaki Collaborate on Smart Hospital with Service Robots

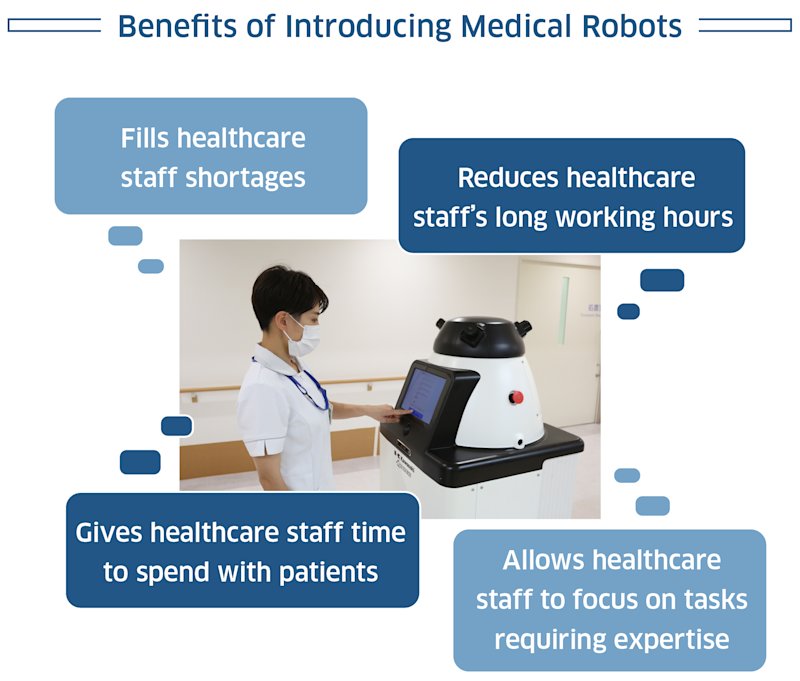

Japan’s declining birthrate and aging population are projected to further increase the demand for advanced medical care. Against this backdrop, the use of robots is one of the most anticipated solutions for streamlining operations and increasing the time healthcare professionals can spend attending to patients.

Is it really possible for people and robots to provide healthcare together? If so, which healthcare services? Fujita Health University and Kawasaki are now conducting demonstration tests on robot functions aimed at jumpstarting the future. This article examines the challenge of introducing robots to healthcare settings, where changes occur all the time and which were said to be unconducive to robots.

Demonstration Testing at One of Japan’s Largest University Hospitals

Fujita Health University, and its associated hospital, are located in Toyoake City, Aichi Prefecture, southeast of Nagoya City. Fujita Health University Hospital is one of the largest hospitals in Japan with 40 clinical departments, an average of 3,200 outpatients per day, 1,376 inpatient beds, and 13,500 surgeries per year.

It is here that Fujita Health University and Kawasaki are jointly conducting demonstration tests of the “Near-Future Mobility Service Robot for Healthcare Operations.” The Phase 3 demonstration test began in August 2022. The Prototype 03 service robot developed for this phase is expected to be the model that will be introduced to the market, possibly already within Japanese fiscal year 2022 (FY2022; April 2022-March 2023).

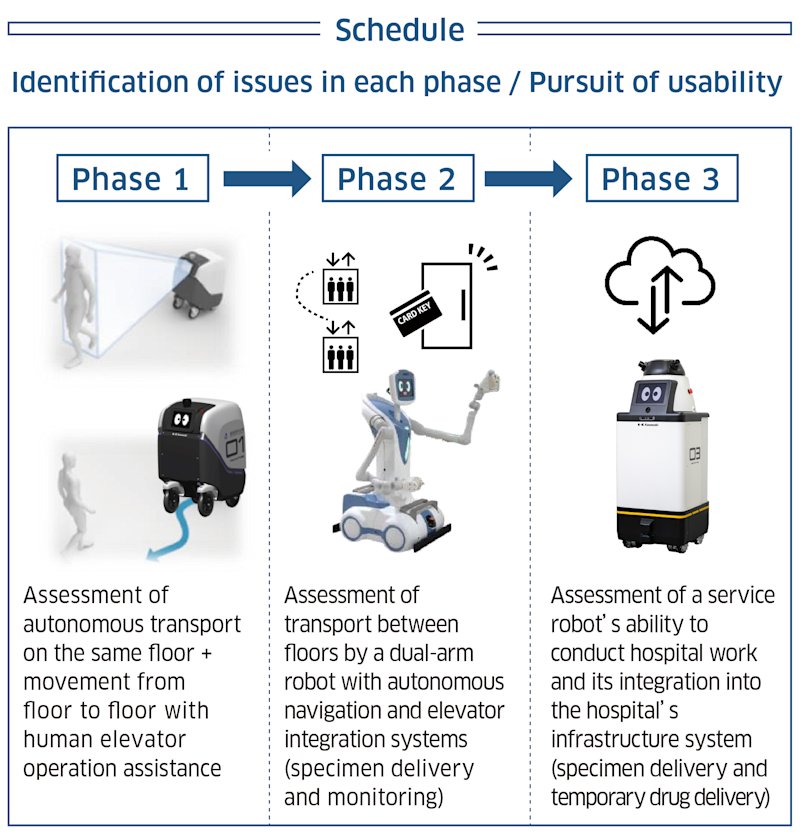

Demonstration testing has been carried out in Phases 1 to 3. In each phase, the team developed hypotheses related to the challenges underlying the needs of healthcare professionals and reconciled the technical requirements with these hypotheses. The robot and the operating applications necessary for the demonstration testing were then prototyped and subject to demonstration tests to further identify the hurdles and functional requirements.

PHASE 1 Identifying Hurdles to Using Robots for the Last Mile in Hospitals

[Phase 1 October 2021]

Phase 1 identified hurdles in sample delivery encountered by the Prototype 01 service robot. It was tested whether this robot could take test specimens from staff stations in two wards on one floor, transport them to the laboratory on another floor using the elevator, and return to the staff stations. The robot developed was square, four-wheeled, and box-shaped with a display monitor on the front that shows facial expressions and information.

According to project member Atsushi Ogura, deputy general manager of Kawasaki’s Global Marketing & Sales Department, the service robot was originally conceptualized to solve the “last mile problem” faced by the logistics industry due to labor shortages.

“We wondered if the service robot could be used in hospitals to reduce the workload of healthcare workers and streamline operations, and that is how we got the idea for the demonstration testing. Fujita Health University has a smart hospital vision for actualizing Society 5.0, and has installed Kawasaki’s automated robotic PCR testing system, as well as Japan’s first surgical robot hinotoriTM. The University has expressed great anticipations for this demonstration testing.”

In Phase 1, the tests found three hurdles needing to be cleared:

(1) Moving between floors

Establishing a method for the robot to self-operate an elevator and move between floors and a method for safely riding an elevator with humans

(2) Stable autonomous navigation

Ensuring stable navigation on routes where obstacles such as carts used by nurses and beds are frequently moved around

(3) Obtaining indoor location information

Establishing an easy method for knowing the robot’s current location

PHASE 2 Discovering the Ideal Width of 55 Centimeters or that of a Person’s Shoulder

[Phase 2 February 2022]

In Phase 2, the team deployed the dual-armed Prototype 02 service robot to test specimen retrieval and other functions, taking into account the challenges observed in Phase 1 demonstration testing.

Prototype 02 was set up to travel to and from staff stations in six wards across three floors and the laboratory, and to use its own arm to tap the IC card required for operating the elevator. The tests also included opening and closing the sliding doors of the treatment rooms in the buildings, taking pictures of patients without opening the curtains, and sending the pictures to the staff station.

One of the purposes of using Prototype 02, which has two arms and a display monitor that turns into a face, was to study how humans and a robot can communicate in healthcare settings. The test studied how facial expressions should be displayed, how the arms can be used to perform a range of transporting tasks, and how to conduct remote communication effectively.

Like General Manager Ogura, Yusuke Kinugawa is a member of this project. He is an assistant manager in the Advanced Smart Mobility Supervisory Department’s System Development Department, which is in charge of developing the robot system. He explains that using Prototype 02 in Phase 2 revealed three more hurdles needing to be cleared:

(1) Smaller robot

Developing a smaller robot that can navigate stably without hitting obstacles and while giving way to patients in the hospital

(2) Robot compatibility with hospital infrastructure and equipment

Classifying which tasks the robot should handle and which it should not

(3) Optimization of compartment space

Creating a secure system for loading and unloading goods in little time

“A key discovery from Phase 2 was ‘55 centimeters.’ That’s roughly the shoulder width of an adult man. If the robot is kept within this width, it will be able to ride an elevator with humans while transporting goods designated by the hospital,” says Kinugawa.

PHASE 3 Fully Autonomous and Automated Travel: Readying for Commercial Production

[Phase 3 August 2022]

In Phase 3, the team developed and introduced a “nearly complete” service robot, taking stock of the two previous demonstration tests. The third prototype is box-shaped, similar to Prototype 01, measuring approximately 55 centimeters in both width and depth, and 140 centimeters in height.

Prototype 03 incorporates the following technologies:

(1) World-leading autonomous travel technology for stable navigation even during the daytime when the hospital is crowded

(2) Fully automated navigation and integration for riding an elevator with humans, which is made possible by smart elevators and automatic doors

(3) Smaller robot so hospital beds and patients in wheelchairs can move around it easily

(4) Indoor location information service iPNT-KTM developed by Kawasaki to visualize the robot’s current location

(5) Optimized compartment space that factors in specimen sizes and work efficiency

Now these technologies are undergoing detailed final-stage verifications.

Koichi Seto, project manager at Fujita Health University and head of the center for co-innovation, states that the dramatic progress made in Phase 3, which paved the way for commercial production, is due to Kawasaki’s outstanding ability to identify hurdles:

“We asked Kawasaki, as the robot developer, to list up the problems in healthcare settings that stand in the way of building a smart hospital. Kawasaki actively held meetings with a range of departments, including our Nursing Department, Laboratory Department, and Pharmacy Department, and created a list of challenges. Kawasaki not only adapted the robot’s functions to these challenges, but it went a step further and developed a robot with general applications. I was amazed and impressed by Kawasaki’s ability to do this.”

Robots Are a Key Component of Smart Hospitals

Service robots designed for healthcare operations are a key component of “smart hospitals.” Fujita Health University is making advanced efforts to build a smart hospital and has set targets in Fujita VISION 2030, which it announced in FY2022.

A smart hospital is one of the management strategies demanded of medical institutions, says Seto. For example, while electronic medical records and other uses of IT have become widespread, they are far from perfect in terms of streamlining the operations of healthcare workers, ensuring convenience for patients visiting the hospital, improving healthcare quality, and linking medical data and systems.

According to Seto, firstly, a smart hospital aims to improve and streamline healthcare operations. Secondly, it aims to achieve digital transformation (DX), including linking various types of data, with the objective of providing extensive high-quality medical services.

For example, DX of medical data envisions creating a uniform information infrastructure that covers health checkups to treatments, medications, and dietary habits.

“Fujita Health University Hospital is a core hospital in the region. In this sense, creating a platform for sharing patient data with local hospitals and clinics will also be an important goal of the Smart Hospital project.”

A big driver of the shift toward smart hospitals is the work-style reform for healthcare workers. From 2024, overtime hours will be capped, requiring phased improvements in the management of working conditions. Depending on the situation, Japan is also forecast to face a shortage of 200,000 nurses by 2025.*1

The automation of operations, or the introduction of robots, is expected to make a significant contribution to improving and streamlining healthcare operations in smart hospitals. The automation of testing work is gradually progressing, thanks to initiatives like the introduction of Kawasaki’s automated robotic PCR testing system. However, the task of transporting things, which is being studied in this project, is an area that has remained unaddressed.

Especially in large hospitals, inpatient testing and intravenous drug administration requires a tremendous amount of in-hospital logistics, including transporting specimens and picking up medication. Most of this work is currently done by nurses and assistants. If the work is simply transporting, does it have to be done by humans?

Seto says, “Services like medical examinations, treatments, and rehabilitation can be performed only by humans. Imagine if testing and transporting work could be substituted by robots whenever possible, and staff could devote themselves to enhancing healthcare services. This is what we mean by using medical resources thoughtfully and efficiently.”

*1:Ministry of Health, Labour and Welfare, “Mid-term Report of the Study Group on the Supply and Demand of Healthcare Workers and the Subcommittee on the Supply and Demand of Nursing Staff,” November 2019

Can Robots Adapt to the Constant Changes of a Healthcare Setting?

As the demonstration testing in Phases 1 to 3 has shown, a hospital environment can vary more than most people imagine. The bed configuration may change depending on the patient’s condition, or emergency equipment may be brought in, leaving no open space. Crowds of healthcare staff may block a robot’s field of vision. Nothing remains the same for even a moment. Humans adapt flexibly to all of these changes in their environment.

Existing service robots, however, do not yet have the technology to respond flexibly and agilely in an environment of constant change. Like industrial robots, service robots are adept at carrying things to the correct predetermined location, provided that the environment is not changing.

“While transporting things may sound like a simple task, from a quality standpoint, robots in healthcare settings have to be developed to be able to protect what they are carrying. The needs and challenges of healthcare settings are wide-ranging, and the deployment of a robot could actually have negative ramifications. That’s exactly why we have to customize the robot in a way that accounts for potential ramifications or challenges, optimize it based on the healthcare setting as a whole, and thereby create momentum for the widespread adoption of such robots.”

The latest demonstration testing of Prototype 03 has shown that it is ready for market launch. Kinugawa explains why this is highly significant:

“Most importantly, we were able to introduce a world-class level of autonomous and automated navigation technologies to healthcare settings, where changes are constantly occurring. Even as staff and patients come and go, the robot can be operated safely, autonomously, and automatically. The more data we accumulate, the more sophisticated, safer, and stabler the navigation technology will become.”

Robots Won’t Do Everything, But They Can Still Do Much More

Robots will not take over all human work. That said, there are still many areas that can be robotized. In order to reduce the workload of pharmacists and reduce dispensing errors, for example, Fujita Health University is preparing a system that uses electronic medical record data and Kawasaki’s robotic arm to pick up cancer drugs from the shelf and dispense them.

Seto describes the future of healthcare as one where staff and robots work side by side and serve patients together.

“First of all, hospital staff need to realize that robots are convenient. For that to happen, we have to deploy a certain number of robots and demonstrate their usefulness to various departments. Each individual healthcare staff member must be able to confirm, for him/herself, the value that robots can provide in healthcare. Once we get there, robots will become commonplace across the medical industry, and technological innovation surely will continue to accelerate as well.”

General Manager Ogura of Kawasaki is also focusing on using robots as solutions.

“We want to build an ecosystem in which our robots serve as a kind of platform, incorporating parts made by other companies to expand our robot’s functions and provide solutions to the various healthcare challenges. We intend to provide advice on the optimal number of robots to be deployed and what routes they should take based on movement and logistics data obtained from the indoor location information service iPNT-KTM. Kawasaki’s strength is not just providing robots, but also making proposals built around actual solutions.”

Robots back up healthcare staff and give them more time to focus on patients. It surely won’t be long before various healthcare needs and aspirations are firmly supported by robots.

Global Marketing & Sales Department

Advanced Smart Mobility Supervisory Department

Presidential Project Management Division

Kawasaki heavy industries, Ltd.

System Development Department

Advanced Smart Mobility Supervisory Department

Presidential Project Management Division

Kawasaki heavy industries, Ltd.

Center for Co-innovation

Innovation Promotion Division

Fujita Health University